Custom Fabrication

Architectural metal cladding is a layered exterior system that protects structure, manages water, and defines visual character. Think of it as a rain jacket for a building that also sets the style. A typical assembly includes a ventilated cavity, air and water barrier, insulation, subframing, and a panel skin. The result is dry walls, stable interiors, and a facade with depth and shadow.

Architectural metal cladding on modern facade with aluminum panels in soft daylight

At its core, cladding separates weather from structure. A ventilated rainscreen promotes drainage and airflow so incidental moisture can escape. Panel geometry, joint design, and flashing details direct water out and away while allowing expansion and contraction. When specified correctly, these systems boost energy performance, extend service life, and lower maintenance.

Durability starts with metal selection and finish. Aluminum resists corrosion, keeps weight in check, and forms easily for crisp edges. Steel delivers high stiffness and impact resistance, especially in thicker gauges or with protective coatings. Zinc and copper bring natural patina, which can be stunning but requires thoughtful detailing. With alum cladding, designers often choose marine grade alloys and powder coat or anodize finishes for long term stability.

Wind loads, seismic movement, and thermal cycling drive fastening strategy. Concealed clips, continuous rails, and slotted holes let panels move without warping. Gaskets and back pans reinforce weather resistance where joints are open by design. Field replaceable panels aid future maintenance without tearing into the wall.

Cladding is a canvas. Flat plate panels create quiet planes while ribbed and corrugated profiles add rhythm and strength. Perforations can tune daylight and airflow and create patterns that shift from near to far. Aluminium metal cladding can be brush finished, anodized in rich tones, powder coated in long lasting colors, or printed for graphic expression. Depth comes from reveals, offsets, and folds that throw precise shadows across the elevation.

Aluminum is a go to for many facade applications due to strength to weight and corrosion resistance. The phrase alum cladding is commonly used to describe these systems. Alloy selection influences forming and longevity. Series like 3000 and 5000 are popular for facade applications, where salt exposure or industrial environments demand robust resistance. Thickness is tuned to panel size, stiffness, and wind pressure.

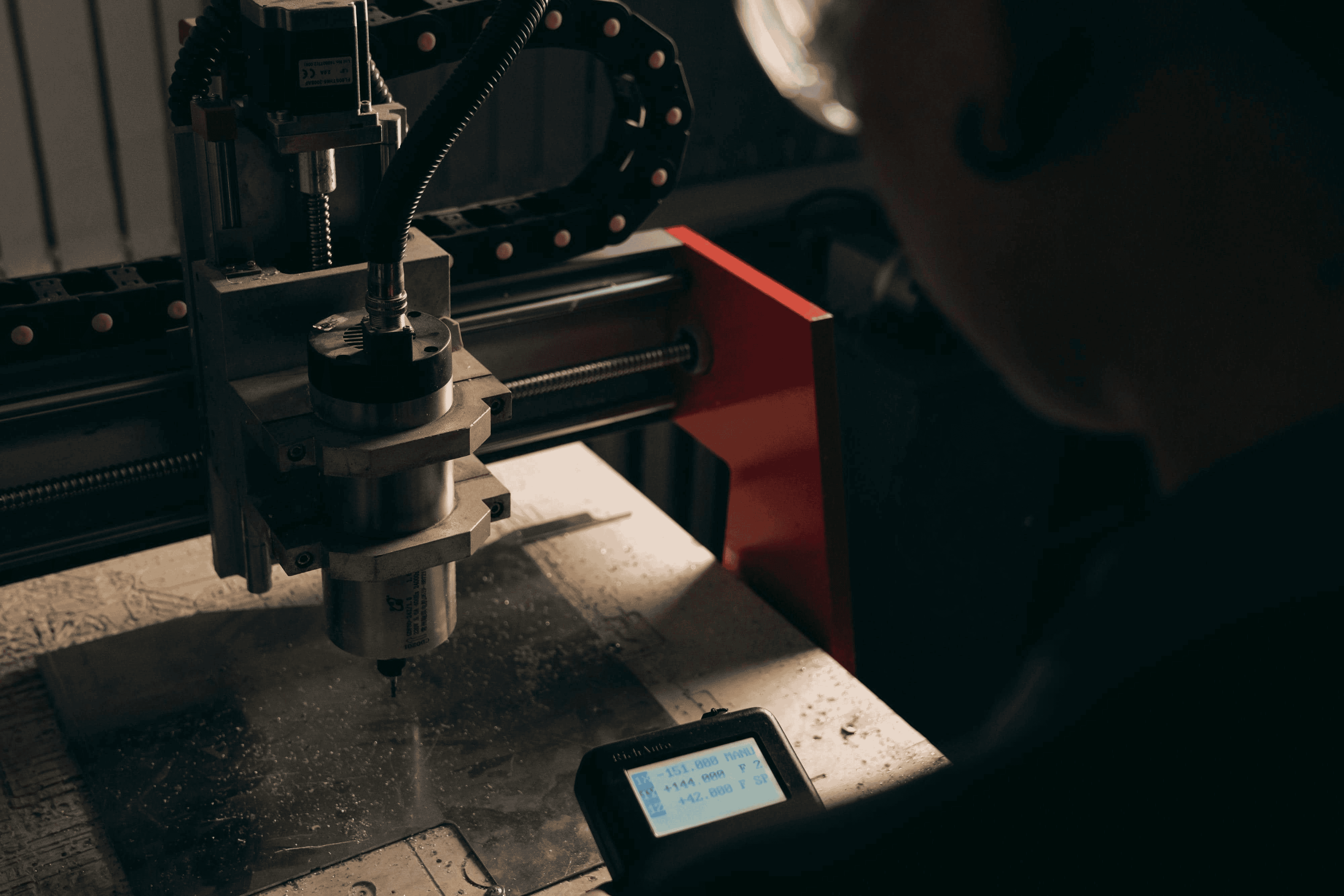

System types range from flat plate rainscreens to cassette panels with returned edges for stiffness. Composite panels sandwich a mineral core between aluminum skins for stable, smooth surfaces when allowed by code. Solid aluminum plate remains a favorite where fire performance and recyclability are priorities. Cladding aluminum often involves CNC cutting, precision bending, and tight tolerances on reveals to keep sightlines true.

Installation planning is everything. A continuous air and water barrier must be intact and properly flashed. Subframing aligns the facade plane and creates a ventilated cavity. Thermal breaks reduce heat transfer through fasteners and rails. Field measurements confirm as built conditions so panel batches arrive ready to fit.

Start with climate, exposure, and building use. Coastal sites push corrosion protection and hardware choice to the forefront. Freeze thaw cycles emphasize drainage and venting. Urban conditions may call for impact resistance and cleanable finishes. Confirm that finish warranties match the environmental demands and orientation of each elevation.

Detail the edges first. Corners, parapets, window returns, and base flashings reveal the discipline of a cladding package. Expansion joints at strategic intervals avoid oil canning and noise during temperature swings. Where open joints are desired, design a durable back pan or baffle that keeps water out of the wall while preserving the shadow line.

Testing and compliance guard the whole design. Look for assemblies that meet water penetration, structural, and fire propagation criteria as required by local codes. Mockups are invaluable. They validate joints, reveals, and color shifts in daylight before full production begins.

When it is time to turn drawings into real panels, precision fabrication makes the difference. OZK Customs supports cladding aluminum workflows with CAD to cut integration, brake formed edges that stay straight, and welds that blend cleanly for a crisp facade line. If you need engineered subframes, perforated features, or specialty brackets, our team can build them to spec and label assemblies for smooth site installation.

Explore our shop capabilities and see how we approach complex builds with custom fabrication. For a deeper look at materials, CNC processes, and finishing options, review our fabrication services. If you want to understand our philosophy and project delivery, read why choose OZK Customs. We operate from Fayetteville Arkansas, central to many project corridors, and we welcome architects, builders, and owners who expect disciplined craft and clear communication.

Your facade sets the tone for the entire building. Share your goals, performance needs, and drawings, and we will help transform them into aluminium metal cladding that installs cleanly and endures.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to translate a cladding concept into precision built panels and subframes? Talk with OZK Customs. Our team designs, fabricates, and installs aluminum and steel systems with CNC accuracy, clean welds, and field friendly details. Share your drawings or ideas and we will quote a solution that fits performance targets, timeline, and budget.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com