Custom Fabrication

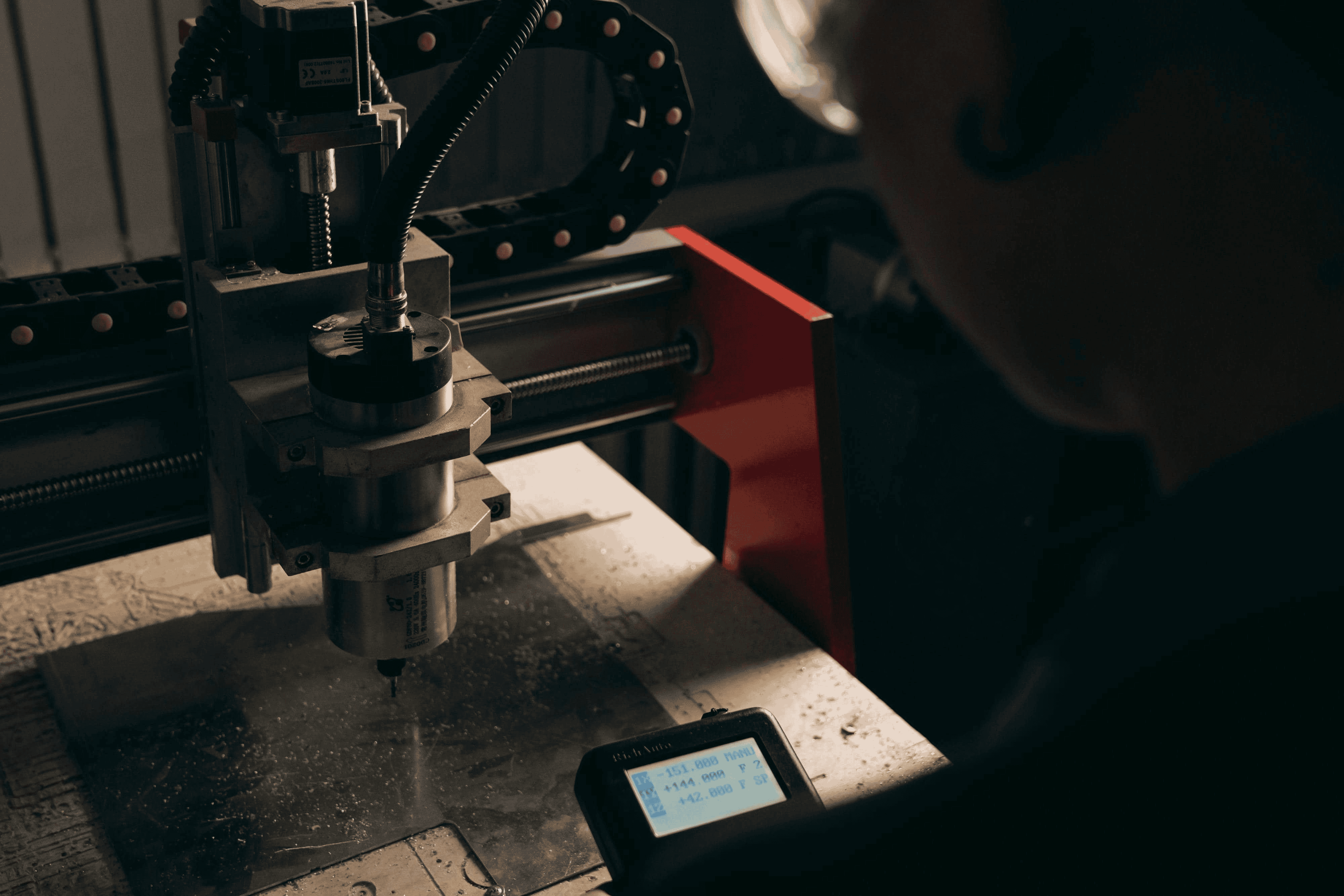

Laser cutting focuses a high energy beam through a lens to melt and eject material along a programmed path. A consistent focal spot, stable power, and a coaxial assist gas create a narrow kerf and crisp geometry. Compared with mechanical methods, the tool never contacts the workpiece, so small tabs, tight inside radii, and delicate features remain intact. The heat affected zone stays limited when parameters are dialed in, preserving strength and surface finish.

Metal laser cutting services rely on fiber or CO2 sources, with fiber lasers dominating for reflective alloys. Aluminium reflects more at typical wavelengths and moves heat quickly, so fiber sources paired with nitrogen or argon assist gas give cleaner edges and less oxidation. With the right optics, thin sheet cuts at high speed and thicker plate progresses with steady pierces and controlled feed.

Tolerances depend on thickness, alloy, and power. For thin laser cut aluminium sheet, positional accuracy in the range of a few thousandths of an inch is common, while thicker stock requires more generous allowances. Edge quality hinges on kerf stability, gas purity, and nozzle standoff. When tuned, parts arrive burr free and require minimal deburring.

Aluminium alloys vary widely. 5052 cuts smoothly and bends well, making it a favorite for enclosures and brackets. 6061 can deliver higher strength with heat treat, but requires careful cutting to prevent micro burring at the edge. Surface conditions matter too. Mill finish behaves differently than anodized or clad stock. Before ordering, confirm alloy temper, thickness, and any coatings to match cut charts and avoid surprises during forming.

For aluminium laser cutting, nitrogen is the go to assist gas for bright edges and a clean cosmetic line. Oxygen increases reactivity, which is useful for some steels but can discolor aluminium. Argon helps on thicker sections or where edge chemistry must stay controlled. Power, duty cycle, pierce time, and lead in strategy define results. Short, ramped pierces limit spatter. Smart lead outs reduce witness marks at the end of a contour. In multilingual specs you may also see aluminium laserschneiden to describe these same parameters.

Good geometry saves time and cost. Keep minimum hole diameters near material thickness or larger for roundness and quality. Allow reliefs at bend lines where features sit close to a brake. Space slots and tabs so heat dispersion remains even. Consider micro joints to hold parts in the nest for downstream handling. Etching and shallow engraving can add panel labels or bend references without secondary operations. These choices help a laser cut aluminum sheet assemble cleanly and look sharp.

Raw parts often need finishing to match the work environment. Light dross knocks off with a quick tumble or brush. Grain direction can be added to enhance appearance. Post processes like anodizing improve corrosion resistance and color matching, while powder coat adds durable texture. If parts will see vibration, deburr edges and break corners to reduce stress risers. For structural components, validate hole to bend distances and keep critical features outside the heat affected zone.

Automotive and mobility applications demand repeatability. Panels must align, brackets must hold loads, and ventilation patterns must stay consistent. That is where experienced programming, verified cut libraries, and controlled fixturing move the job from a drawing to a part that installs without fuss. When the work scales, nesting optimization and material utilization keep costs in check while maintaining delivery timelines.

If you are ready to move a CAD concept into real parts, our team can help with design for manufacturability, nest planning, and finishing. OZK Customs builds adventure vans, overland rigs, and commercial units that depend on precise aluminium components. We integrate laser cut parts into our systems and can support standalone cutting and fabrication projects as well. Explore our custom fabrication capabilities, review detailed fabrication services, and see why choose OZK Customs for quality you can measure. Whether you need a single laser cut aluminium sheet formed and finished or a full kit of brackets and panels, we will guide you from quote to delivery with clear communication and tight tolerances.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn CAD into parts that fit first time? Our team in Fayetteville crafts precise aluminium components for vans, overland rigs, and commercial builds. Share your drawings and tolerances, and we will quote manufacturing plus finishing to deliver installation ready parts.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com