Custom Fabrication

Architectural metal cladding is a protective and expressive outer layer for buildings. It shields the enclosure from rain and wind, controls heat flow, and sets the tone for the visual composition. Unlike load bearing construction, cladding acts as a skin that hangs on a subframe or backup wall, letting the enclosure perform while the facade reads crisp and intentional. Architects reach for metal when they want light weight assemblies, clean lines, fast installation, and a wide spectrum of colors and textures.

Architectural metal cladding facade detail with corrugated metal wall panels

At the assembly level, most projects choose between pressure equalized rainscreens and sealed barrier strategies. Rainscreens create a ventilated cavity that drains and dries. Barrier approaches depend on sealed joints and robust coatings. Either way, continuous insulation, air barriers, and careful transitions at openings do the heavy lifting for enclosure performance. Metal cladding finishes the composition, protects the layers beneath, and carries the design language across elevations.

Beyond weather protection, the right cladding mitigates thermal bridging with thermally broken clips and girts, keeps air leakage low at panel joints, and manages vapor with smart substrates and membranes. Success comes from marrying system selection with project climate, exposure, and maintenance needs. The last step is detailing corners, parapets, and penetrations so the facade reads consistent under close and distant views.

Aluminum remains a favorite for its low weight and extensive coil coated palettes. Galvanized and painted steel brings strength and crisp bend lines, with modern formulations resisting chalk and fade. Zinc and copper reward patient owners with evolving patina, while stainless offers a bright, resilient surface for coastal or high traffic zones. Finish options range from PVDF coil coat to anodized and powder coated looks, with embossed textures that diffuse reflections and limit oil canning.

Architectural corrugated metal panels deliver depth and rhythm at a compelling cost. Profile depth, rib spacing, and gauge control both aesthetics and span capability. When specified as corrugated metal wall panels, they can be structural or installed over sheathing, depending on the backup condition. Exposed fastener patterns can become part of the graphic language, while concealed fastener variants give a cleaner read with improved water management at laps.

Corrugated panels do more than dress a facade. Perforated versions manage sun and sightlines while keeping ventilation. Thicker gauges and deeper profiles reduce deflection, and clip systems allow movement to limit waviness. Specifying panel length to suit thermal expansion helps control joint alignment across long runs. At grade, robust base flashings and impact resistant gauges protect the envelope where traffic is highest.

Good details start at edges. Hemmed corners resist oil canning and hold lines true. Sill and head flashings must kick water clear of the wall and manage air seal transitions. Fastener type and spacing should match wind load calculations, and stainless or coated hardware prevents staining. Verify water, air, and structural performance data from panel testing, and field test mockups to fine tune joint design before full installation.

Architectural metal systems include panels, subframing, clips, fasteners, trims, and sealants that work together as one enclosure strategy. Thermally broken girts support panels over continuous insulation, while ventilated cavities keep the wall dry. Clear transitions at windows, doors, and parapets preserve the control layers. Coordination with glazing, signage, and lighting channels ensures attachments do not compromise the air or water barrier.

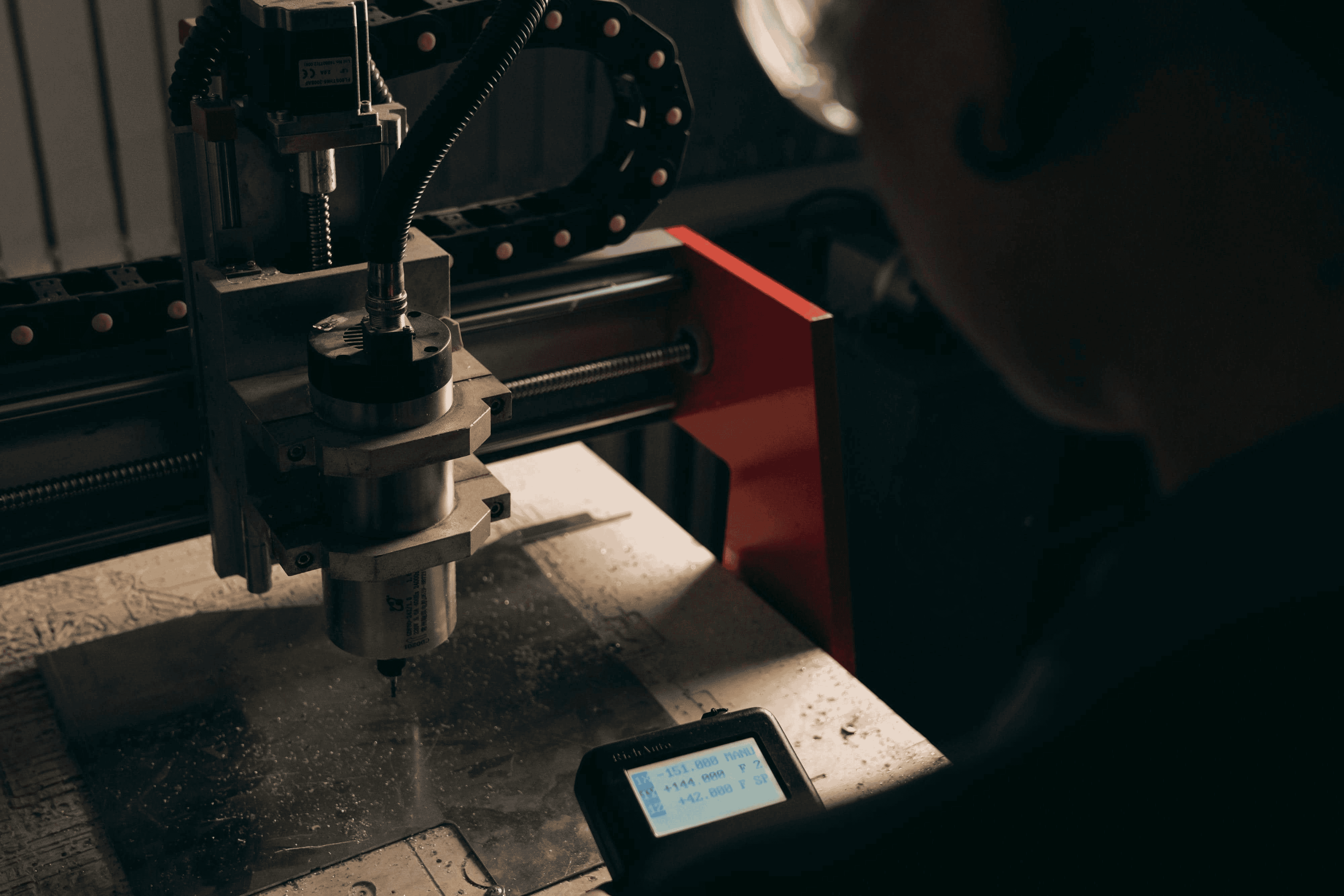

Digital workflows streamline delivery. Parametric modeling and panelization rules prevent awkward slivers and align ribs with datum lines. Shop drawings and nested cut files translate design intent into parts with tight tolerances. On site, sequencing and protection measures keep finishes pristine. With thoughtful planning, metal cladding becomes a durable, repairable surface that still looks sharp years after turnover.

Initial price is only part of the equation. Consider total cost of ownership, including cleaning cycles, expected coating life, and ease of replacement. PVDF finishes typically hold color and gloss for decades with basic washdowns. Where damage risk is higher, choose heavier gauges or modular panels that swap out without disturbing adjacent areas. A clear maintenance plan preserves warranties and protects the investment.

If your project requires custom trims, specialty brackets, or unique panel geometries, a fabrication partner can shorten the path from design to installation. OZK Customs supports architects, builders, and owners with precision CAD to part workflows, CNC routing, plasma cutting, and custom metal fabrication tailored to architectural cladding needs. Explore our custom fabrication capabilities, review our dedicated fabrication services, and see why choose OZK Customs for partner level collaboration from concept through mockup.

Whether you need corrugated profiles with precise trims, complex corners that resolve tricky geometries, or project mockups to validate seams and joints, we can help you move from schematic to shop ready with clarity and speed. Tell us about your facade goals, timeline, and finish targets, and our team in Fayetteville Arkansas will suggest a path that balances aesthetics, performance, and budget.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a concept sketch into fabricated reality? OZK Customs translates drawings into precise panels, trims, and brackets using CAD, CNC routing, and custom metal fabrication—then verifies fit with project mockups. Tell us about your facade, timeline, and finish targets, and we will quote fabrication and prototyping to move your building forward.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com