Custom Fabrication

Architectural metal cladding is both shield and signature. It protects the primary wall, manages moisture and heat, and gives the facade its character. Done well, it integrates weather control layers, continuous insulation, and sub framing so panels can breathe while staying secure and straight. The result is a durable, serviceable exterior that looks refined for decades.

Architectural metal cladding and exterior wall panels on a modern facade with aluminum finish

Most architectural exterior wall panels land within rainscreen logic. A ventilated cavity sits in front of the air and water barrier and continuous insulation, allowing incidental water to drain and the wall to dry. Sub framing transfers wind and dead loads back to structure while maintaining thermal breaks to reduce bridging.

Common panel families include single skin profiled sheets, plate panels, composite metal panels, and standing seam. Single skin options range from ribbed and corrugated to custom brake formed profiles for crisp shadow lines. Plate panels use thicker aluminum or steel, offering flatness and depth for large modules. Composite metal panels sandwich a core between thin metal skins and often require tested assemblies for fire compliance. Standing seam systems create continuous vertical or horizontal lines with concealed clips that allow movement.

Material selection shapes lifespan and maintenance. Aluminum is light, corrosion resistant, and receptive to high performance coil coatings. Galvanized or coated steel brings strength and impact resistance. Zinc develops a protective patina and suits coastal or damp climates when detailed correctly. Copper evolves from bright to rich brown and eventually verdigris. Stainless offers exceptional corrosion resistance and a distinct sheen for high traffic or harsh environments.

Finishes broaden the palette. Fluoropolymer coil coatings deliver color stability and chalk resistance. Anodized aluminum gives a metallic, depth rich appearance and holds up well to abrasion. Brushed and bead blasted textures mute reflections and hide minor wear. Perforations and profiles add rhythm and transparency while enabling acoustic strategies when combined with liners.

A successful envelope resolves physics first, then form. Consider these drivers when evaluating architectural wall panels and architectural siding panels.

Attachment strategy sets the tone for speed and quality. Rails and hats create a plumb plane over uneven substrates. Factory punched parts help maintain joint consistency. Weather barrier and flashing sequencing matters more than anything. Through wall flashing at openings and transitions defends against water paths that would otherwise bypass the exterior line of defense.

Acoustics and comfort can be addressed with perforated single skin or composite faces paired with mineral wool or acoustic mats in the cavity. At the same time, solar reflectance and emissivity of finishes influence heat gain and reduce cooling loads in sunny climates.

Architectural siding is often specified along with other facade materials such as fiber cement, masonry, and glass. Thoughtful transitions between systems protect edges and simplify maintenance. Simple access paths for cleaning, such as lift points and panel removal strategies, extend the life of architectural exterior wall panels without elevating operating costs.

As you evaluate options, test samples under real light and viewing distances. A finish that looks perfect in a hand sample can behave differently at scale. Consider how the facade will age and what cleaning methods will be used. Document maintenance expectations, from gentle detergent wash schedules to periodic inspections of sealant free joints, clips, and fasteners.

Keep the air and water barrier continuous, integrate pan flashings at penetrations, and design rainscreen cavities with drainage and ventilation. Select thermally broken brackets to preserve R value while maintaining structural capacity. These fundamentals protect the building and anchor the performance of the cladding.

Confirm assembly testing and follow regional codes for height and proximity. Coordinate wind loads, pullout values, and seismic movement with the structural team. Use compatible materials to prevent galvanic corrosion and isolate dissimilar metals where needed.

Choose fluoropolymer coatings for color retention, anodized metal for a metallic effect, or textured plates to diffuse glare. Set realistic cleaning intervals based on climate and exposure. Detail corners and terminations to resist impact and channel water away.

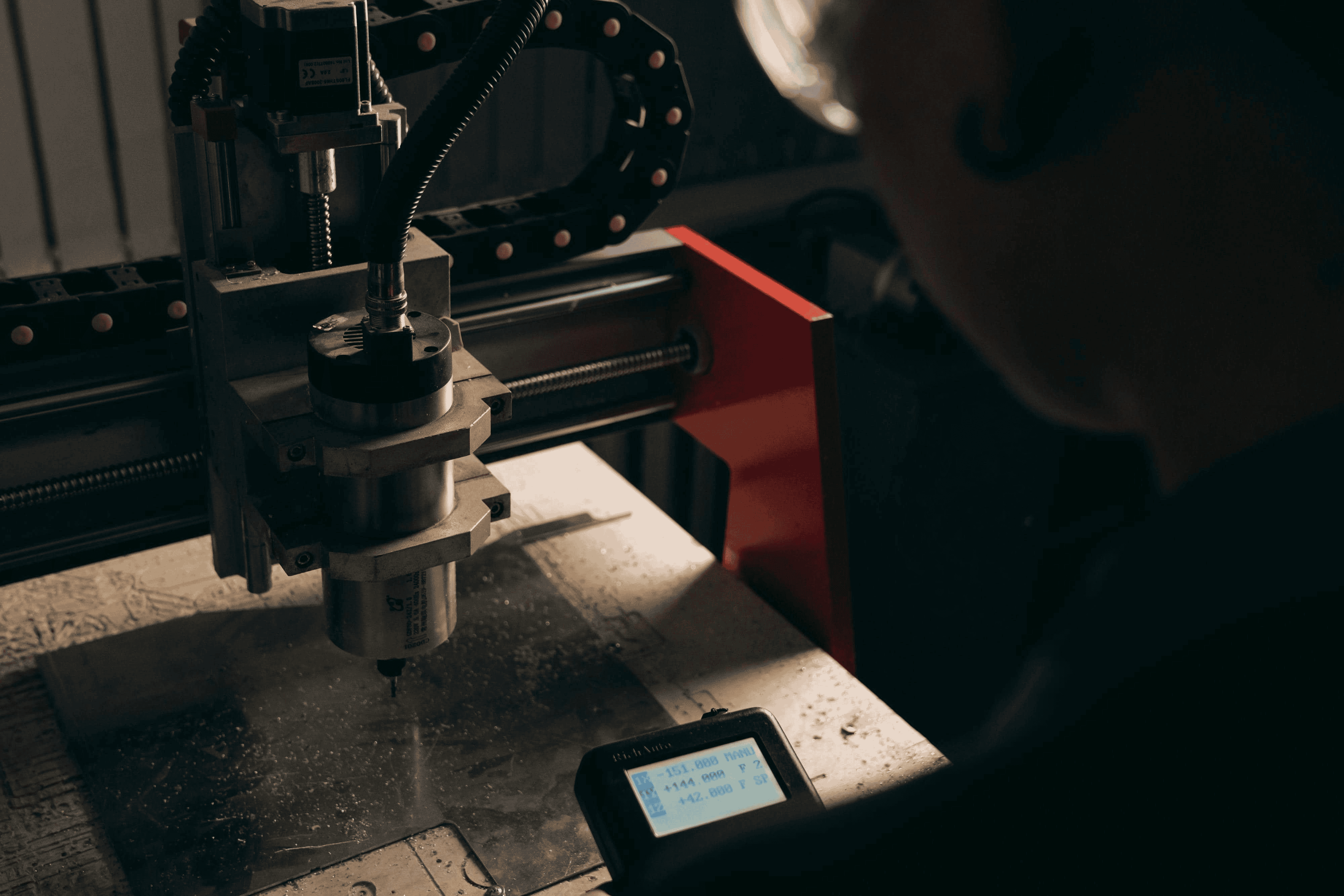

Within this complexity, fabrication quality drives outcomes. If your project needs precise brake forming, kitted sub framing, or custom profiles, explore our custom fabrication solutions. For a deeper view of how we cut, bend, and finish assemblies that fit right the first time, see our fabrication services. Curious about our process and team standards that keep projects on schedule, visit why choose OZK.

We partner with architects, builders, and owners to translate design intent into buildable, install ready packages. From shop drawings and CAD to precise metalwork and labeled kits, OZK Customs aligns aesthetics with installation efficiency. Based in Fayetteville Arkansas, we ship nationwide and support on site coordination so your architectural exterior wall panels install cleanly and perform as modeled.

Bring us your elevations and preferred materials. We will advise on thickness, module size, sub framing, and finish, then fabricate the components that make the facade work day one and year ten. When you are ready to move from inspiration to execution, our team will help you choose the right architectural siding panels and deliver the pieces that make your building stand out and stay protected.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn your concept into a buildable facade package? Tell us about your timeline, budget, and aesthetic. OZK Customs will translate your drawings into engineered, fabricated, and install ready components. Share your project details today and get a precise path from design to delivery.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com