Custom Fabrication

Metal bending services transform sheet and plate into functional shapes by applying controlled force along a defined line. The core objective is to achieve a target angle and radius while preserving strength and dimensional fidelity. This requires understanding how metals deform, where material stretches and compresses, and how to account for elastic recovery that occurs after unloading. The result is a bent steel part that fits and performs as designed.

At the heart of bending is the neutral axis, an internal layer that neither stretches nor compresses during the bend. Designers rely on bend allowance and bend deduction to predict the developed flat size so parts form to spec. The K factor, a ratio tied to the neutral axis shift, helps dial in these calculations for different materials and thicknesses. Getting this math right improves fit up and eliminates rework.

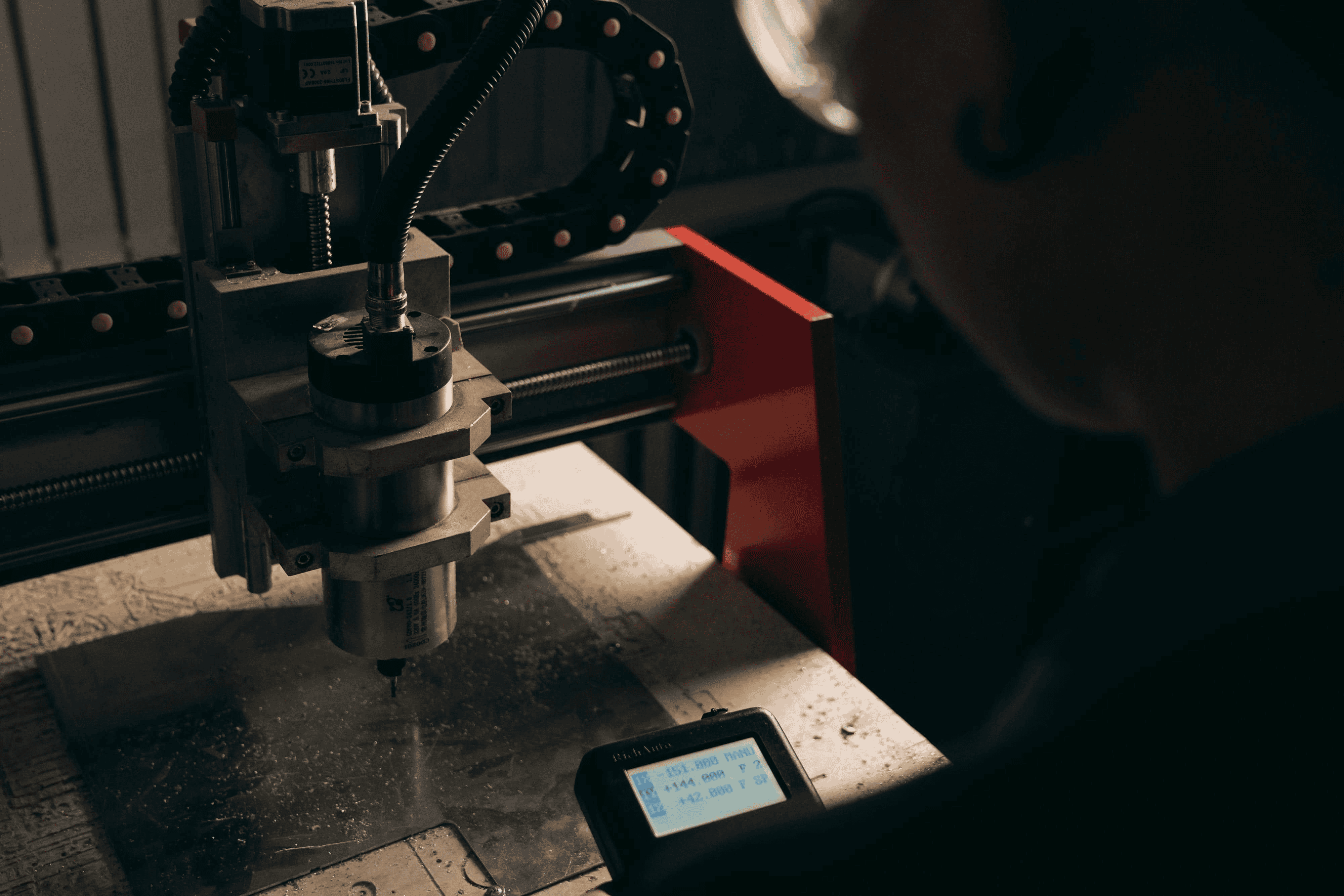

Metal bending services using a CNC press brake to form a bent steel plate with precise radius and angle control for consistent results

Material behavior drives choices in process and tooling. Low carbon steel like A36 bends easily with generous radii. Higher strength plate such as A572 or quenched and tempered grades demands larger inside radii to avoid cracking. Stainless steel work hardens and typically requires a larger die opening or a larger punch radius. All of this influences how to form a bent steel plate without defects.

Springback is the elastic rebound after the tooling releases. Thicker plate, higher strength steel, and larger radii tend to increase springback. Shops counter this with overbending angles, choosing tooling with the right punch radius, and sometimes by bottoming or coining to lock in the angle. Accurate angle sensors, CNC crowning, and consistent back gauge pressure also help maintain repeatability.

Grain direction matters, especially with thicker plate. Bending parallel to the rolling direction increases the risk of edge cracking on tight radii. When possible, orient bends perpendicular to grain or increase the inside radius. For critical parts, a quick coupon test can confirm safe limits before forming the full batch.

Most plate work happens on a press brake using air bending, bottoming, or coining. Air bending is the most common and flexible, using a punch and V die without fully seating the material. The angle is controlled by stroke depth, and a single setup covers many angles. Bottoming seats the material on the die shoulders for more stability with less springback. Coining compresses the bend line with high tonnage to lock the angle, often used for thin gauges when ultra tight tolerances are required.

Die selection is central to quality. As a rule of thumb, the V die opening for steel is often six to ten times the material thickness to balance tonnage and radius. A punch radius near one times thickness generally produces a robust inside radius for mild steel. For bent steel components that will see cyclic loads, larger radii reduce stress concentration and extend service life.

When plate gets thick or the profile is gentle, three roll or four roll bending creates arcs and cylinders that press brakes cannot efficiently achieve. Rolling produces smooth contours for tanks, guards, and structural shells. Complex parts may combine rolling and press brake operations, sequencing bends to avoid collisions and preserve datum features.

Design choices can make forming cleaner and faster:

Quality control centers on angle accuracy, flange length, flatness adjacent to the bend, and edge condition. Measuring with calibrated angle gauges or laser systems confirms output. Inspect for crazing, micro cracks at the edge, and thinning on the outside surface, particularly in high strength plate. For welded assemblies, verify that the bend geometry supports proper fit up without forcing, which can introduce residual stresses.

Yield strength, ductility, and thickness define how far steel can bend before damage. Cold forming preserves base material properties but requires respect for minimum radii. Hot forming can reduce force and risk of cracking, yet it may alter mechanical properties and typically needs post bend normalization or stress relief for critical applications.

Press brakes with CNC crowning and angle measurement deliver consistent angles across long flanges. Back gauge fingers and staged tooling reduce handling and cycle time. For bent steel plate with long legs, support arms and proper handling prevent distortion and scratches that affect downstream coating or assembly.

Bending plate involves high forces and heavy parts. Use lifting aids, verify clamp integrity, and keep hands clear of pinch points. Deburr edges and remove scale where the material contacts tooling to improve finish and extend tool life.

Knowing when to involve a professional shop can save time and material. If the part requires tight angles across long bends, multiple setups, or forming thicker plate that approaches tonnage limits, experienced operators, correct tooling, and CNC press brakes become essential. Tolerance stacking, springback variation, and safe handling are all managed best with calibrated equipment and proven process control.

If you need a partner to turn drawings into precise bent steel, our Fayetteville, Arkansas team can help. We handle one offs and production runs, validate bend deductions, and advise on reliefs, radii, and sequencing that make fabrication smoother. Explore our custom fabrication capabilities to see how forming integrates with cutting, welding, and finishing. For a deeper look at forming, cutting, and design support under one roof, review our fabrication services. If you are evaluating vendors, learn more about our approach, team, and quality standards at why choose OZK Customs.

When your project calls for a bent steel plate with reliable angles and clean edges, bring us your print or concept. We can recommend material grades, set inside radii that protect strength, and build forming programs that repeat from the first part to the last. Share the application and environment, and we will tune the process for the outcome you need.

Precision forming without the guesswork starts here. Our process combines solid math, smart tooling, and careful inspection, so your parts assemble right the first time and hold their shape in the field. Tell us about your timeline, volume, and finish requirements and we will shape a plan that fits your build.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn flat plate into strong, accurate parts? Our Fayetteville team forms steel with tight tolerances, clean edges, and predictable results. Share a print or concept and we will guide material, bend radii, reliefs, and finishing to deliver production quality parts built for the field.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com