Custom Fabrication

Welding certification confirms a welder can deposit sound welds to a given procedure and position. Welding inspector certification focuses on evaluating those welds and the systems around them. A certified welding inspector protects safety, schedule, and cost by confirming compliance with codes, procedures, qualifications, and documentation before issues migrate into the field.

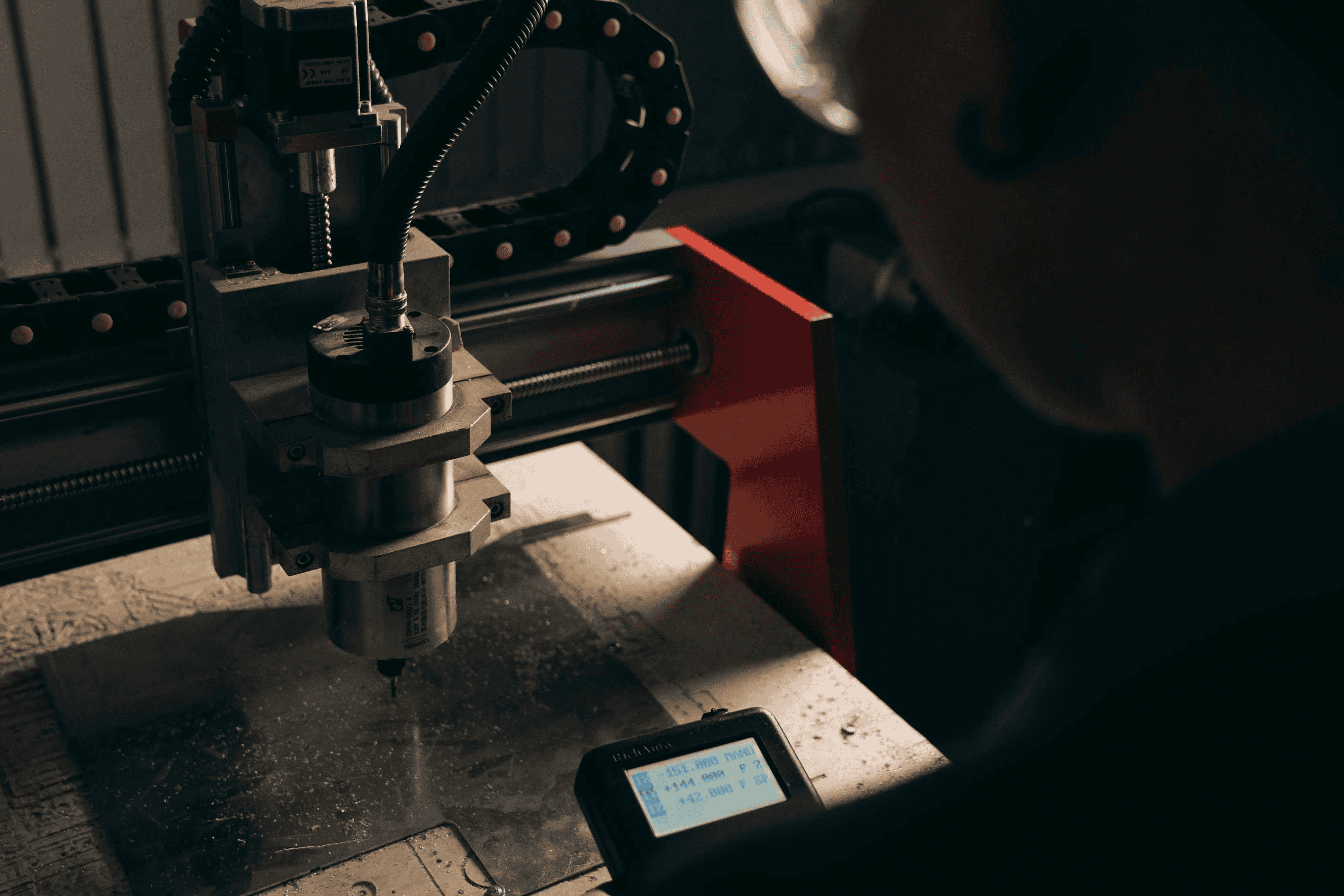

Certified welding inspector performing CWI inspection to AWS code in a fabrication shop

While many organizations issue welder performance qualifications, the American Welding Society sets the benchmark for inspector credentials. The aws certified welding inspector program validates knowledge of metallurgy, process variables, discontinuities, acceptance criteria, and inspection methods. In practice, cwi inspection work spans material verification, procedure and welder qualification review, fit up checks, visual examination, weld size measurement, and coordination of nondestructive testing.

CWI welding oversight is not about redoing the craft. It is about verifying that craft is executed within the boundaries of the specified code, procedure, and drawing set. The certified welding inspector becomes the objective voice on quality, ensuring traceability, documentation, and clear communication between engineering, production, and the client.

Certified welding inspector requirements are defined by AWS and include education and experience combinations, a recent vision test, and ethics compliance. Candidates with more education need fewer years of experience, while those with less formal schooling need more documented time in welding, inspection, or related work. A near visual acuity test and color differentiation capability are required, because inspection hinges on detecting small surface indications and reading color coded materials.

The aws cwi certification exam has three parts. Part A covers fundamentals such as welding processes, heat flow, materials, symbols, safety, and testing methods. Part B is practical, where you inspect plastic replicas, measure welds, calculate fillet sizes, and identify discontinuities using tools like gauges and calipers. Part C is code based, using a specific codebook selected for the exam. Many choose structural steel, but piping and sheet metal options exist. Time management and fluency with code navigation are key to success.

Initial certified welding inspector certification is valid for three years, with a renewal at years three and six. At nine years, recertification involves continuing education, points from professional development, or retesting. Maintaining skills through seminars, job rotations, and mentoring strengthens judgment, especially when balancing code minimums with project specific criteria and client expectations.

To pursue welding inspection certification, gather verifiable work history, training records, and references. If you do not yet meet the full requirement, the associate level credential can be a bridge. The CAWI allows you to work under a CWI inspector while you build experience toward full status.

Success on the certified welding inspector certification exam hinges on practice and familiarity with code layout. Learn table structures, definitions, and footnotes. During Part B, slow down, measure twice, and apply acceptance criteria exactly as written rather than by habit.

Many inspectors widen their scope with procedure qualification records, welder testing, and oversight of NDT. Experienced professionals may advance to SCWI, audit quality systems, or lead crews on complex builds where documentation and traceability are mission critical.

Here is how to become a certified welding inspector in a clear progression. Confirm eligibility against the published matrix, schedule an eye exam, and submit your application early to secure an exam date. Choose the codebook that matches your industry focus and practice navigating its clauses, tables, and figures. Build fundamentals through study guides and sample questions, then drill the Part B practical with gauges, inspection replicas, and timed sessions. On test day, bring permitted tools, plan your pacing, and read every question carefully.

The aws certified welding inspector credential opens doors across sectors. Structural steel, pipeline, pressure vessels, shipbuilding, and heavy equipment all rely on inspectors who can translate drawings and codes into clear acceptance decisions. A cwi certified welding inspector earns trust by documenting what was observed, not what was assumed, and by communicating findings in plain language that drives corrective action without inflaming the jobsite.

New inspectors benefit from shadowing veterans, developing a personal checklist, and reviewing rejected samples to calibrate their eye. Remember that cwi welding oversight is a systems job. You are evaluating procedures, qualifications, materials, fit up, weld execution, and post weld actions together, not in isolation. Strong inspectors learn the why behind each clause so they can apply judgment when the job throws unusual joints, positions, or constraints at them.

Ethics matter. A cwi inspector must be independent, consistent, and thorough. When schedule pressure grows, your role is to hold the line at the acceptance criteria that protects safety and performance. That is the value of welding inspection certification. It makes your decisions defensible in the field and in the record.

If you are planning a fabrication project that has to stand up to code reviews, start with a team that respects standards from day one. At OZK Customs in Fayetteville, Arkansas, our shop culture centers on clear procedures, material traceability, and inspection ready welds. Explore our custom fabrication capabilities, review our core fabrication services, and see why choose OZK for builds that align tightly with specification and documentation from kickoff through handoff.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to build with inspection grade quality? Talk with OZK Customs in Fayetteville, Arkansas about code guided fabrication, documented procedures, and inspection ready welds. Share your project details now and we will map a clean, standards aligned path from concept to handoff.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com