Custom Fabrication

Metal laser cutting services use concentrated light to melt or vaporize a narrow path through metal, guided by CNC motion control. Most shops run fiber lasers for excellent efficiency and speed on steel, stainless, and aluminum. Assist gases like oxygen, nitrogen, or shop air accelerate the cut and influence edge color and finish. The focused spot produces a narrow kerf, which improves detail, reduces waste, and supports close part nesting. With a stable setup and clean optics, consistent results are achievable across short runs and large batches.

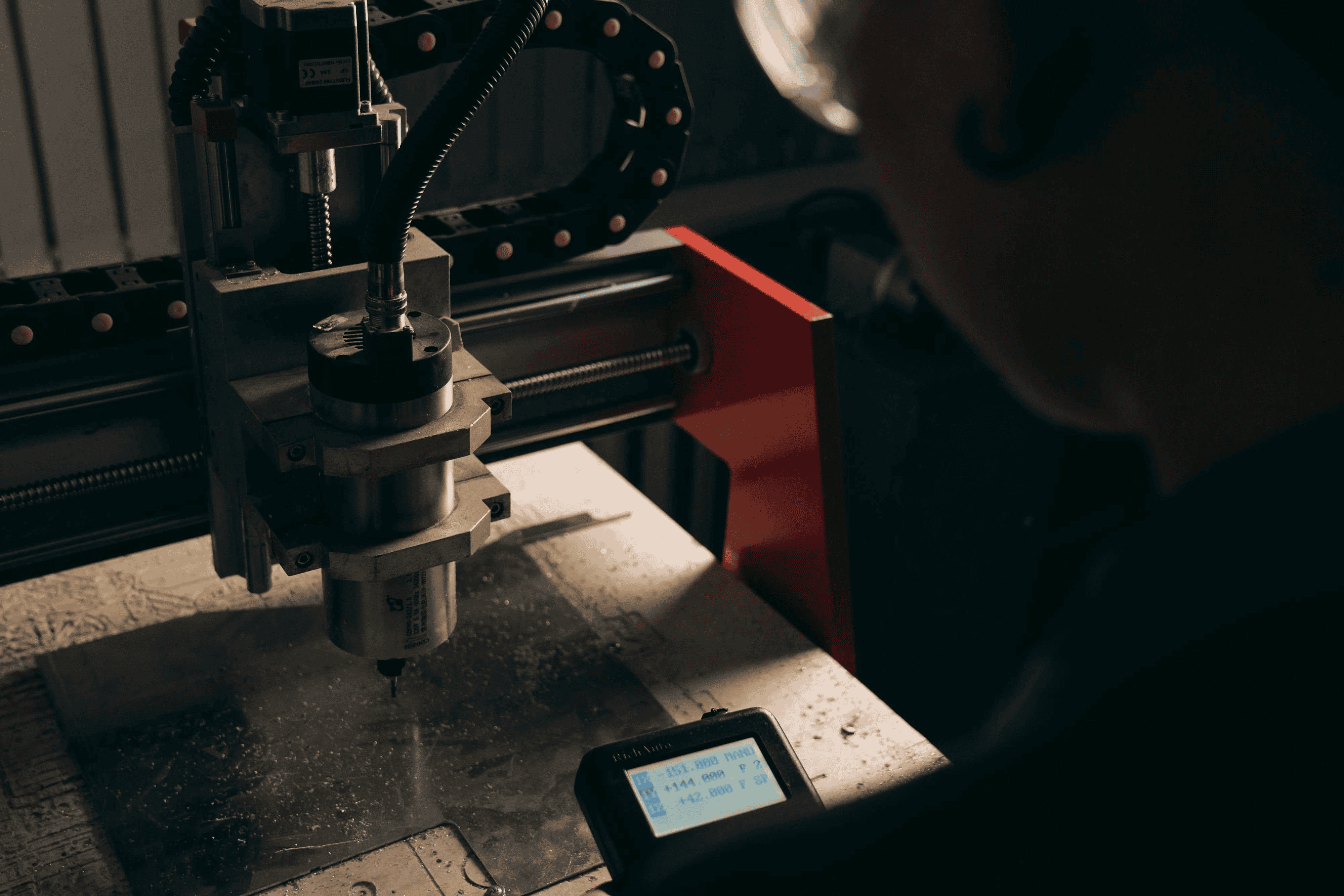

Close up of metal laser cutting services achieving tight tolerances on stainless sheet at OZK Customs Fayetteville Arkansas

Kerf is the material removed by the beam, often in the range of tenths of a millimeter depending on lens, nozzle, and material thickness. Because the beam is so small, lasers hold tight positional accuracy and produce fine internal features like slots and small holes. Heat affected zones remain minimal when parameters are tuned, which helps preserve material properties near the cut line. For most sheet projects, this process supports production level repeatability with predictable fit up during forming and welding.

CNC custom cutting describes computer controlled profiling across multiple processes, including laser, router, plasma, and waterjet. Each method shines in specific scenarios. If you need fast turnaround on intricate sheet metal parts with tight hole to edge distances, laser is often the best fit. If you require thick plate, exotic alloys, or zero heat input, waterjet may be the better path. Plasma moves quickly on structural thicknesses with a lower entry cost. A router excels on non ferrous stock and composites with excellent surface finishes when proper tooling is used.

Consider the whole workflow, not just the cut. Laser parts usually need minimal deburring and arrive ready for forming or weld fixtures. Waterjet edges are cold cut but may require more cleanup. Plasma edges can have dross that needs removal. Router edges can be very smooth with the right feeds, speeds, and chip evacuation. For production parts, nesting efficiency and cycle time matter. Lasers typically provide the best combination of speed, detail, and material utilization for sheet goods.

Common laser materials include mild steel, stainless steel, and aluminum in a wide range of gauges. Nitrogen assist helps keep a bright edge on stainless, which is useful for visible panels. Oxygen assist can increase cutting speed on steel while leaving a darker oxide edge that is fine for painted components. If you plan to powder coat, a clean edge and light surface prep yield strong finishes. Always communicate final finishing steps so cut parameters prioritize edge quality over raw speed where it matters.

Metal routing services use a CNC router with end mills or specialty cutters to remove material mechanically. Routers are outstanding for aluminum plate, copper, brass, and many plastics. They can achieve excellent surface finishes, pocket features, and countersinks in one setup. Fixturing is important to prevent part movement, and correct chip load with sharp tooling limits burrs. Compared to laser on thin sheet, routing is usually slower on profiles but shines when parts need milled features or when materials are sensitive to heat.

If you work with composite skins, honeycomb panels, or laminated materials, a router gives strong edge control and supports diverse tool paths like chamfers and radius edges. For decorative panels and enclosures, routing delivers crisp countersinks and threaded inserts ready locations. When deciding between laser and router, match the process to the material, tolerances, edge requirements, and downstream operations like forming, welding, or anodizing.

Metal laser cutting services are often the fastest way to go from CAD to parts with excellent accuracy. When your project needs full fabrication support beyond cutting, look for a shop that can form, weld, and finish under one roof to avoid delays and alignment issues. Explore how our team approaches advanced cutting and assembly on the custom fabrication page.

For a deeper dive into capabilities like CNC routing, forming, and precision welding, review our fabrication services. If you want to see what sets our operation apart in quality control, communication, and delivery, visit why choose OZK Customs.

If you know your material, thickness, and finish, we can turn that plan into finished parts. Send DXF or STEP files, call out critical tolerances, and we will confirm the best process between laser, CNC custom cutting, or metal routing services. Our shop in Fayetteville Arkansas can cut, form, and weld your components into complete assemblies, then finish and test before handoff. Whether you need one prototype or a production run, our team delivers parts that fit on the first try and integrate cleanly into your build.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready for production grade parts without guesswork? Send your drawings and goals. OZK Customs will review your files, confirm tolerances, optimize nesting, and provide a clear quote with timelines. From single prototypes to full batches, we deliver accurate cuts and finished assemblies that fit right the first time.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com