Custom Fabrication

CNC metal machining is a digital manufacturing process where computer controlled tools shape metal into final geometry. The workflow begins with a solid model and a clean drawing, then CAM software generates toolpaths for milling, turning, or drilling. A metal cnc machine executes those paths with stable feeds and speeds so features land within tolerance. From simple brackets to complex housings, the result is consistent metal machining parts that match the print.

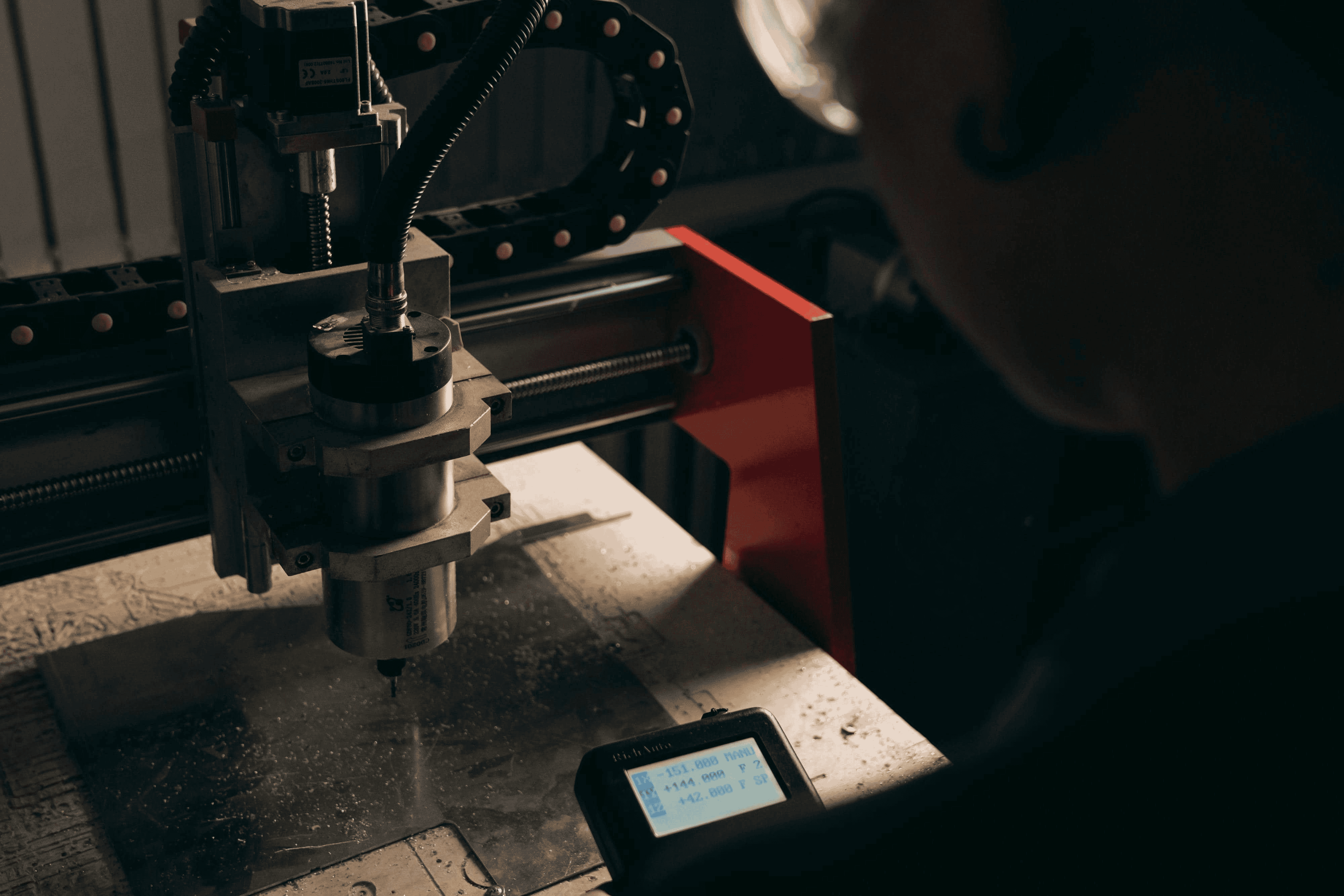

CNC metal machining services producing precision metal machining parts with surface finishes and tight tolerances

Modern shops combine operations to reduce setups. A five axis mill can cut multiple faces in one clamping, while a turn mill blends lathe work with live tooling for slots and holes. Probing on the machine verifies datums before cutting and checks critical dimensions after roughing and finishing. Inspection often includes calipers, micrometers, bore gauges, and coordinate measuring machines for higher accuracy.

Tolerances are the allowable size variation on a feature and they drive time and cost. General tolerances like plus or minus five thousandths of an inch are quick to hit, while tighter ranges require careful tool selection and lighter finishing passes. Surface roughness also matters. Fine finishes may call for smaller stepovers or dedicated reamers after drilling. Flatness and parallelism are controlled with stable fixturing and measured with surface plates or a CMM.

Material choice guides feeds, speeds, and tool wear. Aluminum machines quickly and suits prototypes and lightweight parts. Carbon steel and stainless steel cut slower and generate more heat but bring strength and corrosion resistance. Titanium demands rigid setups and sharp tooling. After machining, finishes such as anodizing, black oxide, zinc plating, or powder coating can add protection and a clean look. Threads may be cut or formed, with callouts matching standards like UNC or metric.

Clear manufacturing data reduces questions and lead time. A production ready drawing should call out dimensions, tolerances, thread specs, and any heat treatment or hardness. Notes for deburring, edge breaks, and surface finish keep expectations aligned. If a part mates to another component, include a reference assembly or key interface dimensions. When features are hard to measure, specify inspection method so reports match your needs.

Quoting reflects real process steps. Setup time covers fixturing and programming. Cycle time captures the actual cutting. Material cost depends on alloy, bar or plate size, and drop utilization. Secondary operations like tapping, reaming, broaching, or assembly add line items. Inspection levels range from basic checks to full dimensional reports with material certs and finish certs.

CNC steel fabrication blends machining with forming, laser or plasma cutting, and welding to deliver robust assemblies. Flat parts can be cut, bent, and then machined at critical interfaces to hold tight fits. Housings may start as a weldment and finish on the mill to square faces and bring bores on size. This hybrid approach keeps structural strength while achieving precision where it counts.

A solid CAD model streamlines this flow. Designers can add machining allowance on welded features, plan datums that survive fabrication, and include tabs or slots for accurate locating. Tooling plates and soft jaws help position parts consistently across batches. For critical bores or keyways, a finishing operation after coating preserves final dimensions.

Choosing the right partner for metal machining services hinges on capability and communication. Look for evidence of consistent tolerances on similar metals, the ability to run both prototype and production, and a clear plan for inspection and documentation. Ask how they manage fixtures, tool life, and dimensional drift over long runs. Confirm that the shop can work with your native CAD and preferred drawing standards.

Now, for builders who need precise brackets, racks, and structural components that marry style with strength, thoughtful machining meets real world use cases. OZK Customs integrates machining and fabrication for parts that bolt up cleanly on day one. Explore our in house and partner based workflow through our custom fabrication page, then review the breadth of fabrication services we apply to vehicle builds and overland gear. If you want to see how we approach outcomes and communication, visit why choose OZK Customs to understand our process and values.

Whether your print calls for cnc steel fabrication or a metal cnc machine workflow for aluminum, our team translates drawings into ready to install parts. That includes tight interfaces for roof racks, precision tabs for weldments, and machined pads that accept seals or bearings. We coordinate finishes so assemblies look sharp and resist corrosion in the wild.

Bring your design, material, and target tolerance, and we will help move it from a validated prototype to a repeatable production run. Our goal is simple. Metal machining parts that fit, function, and perform through thousands of miles.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready for precision parts that fit your vehicle build right the first time? Tell us about your timeline, material, and finish. OZK Customs will translate your drawings into production ready components and assemblies through our custom fabrication process.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com