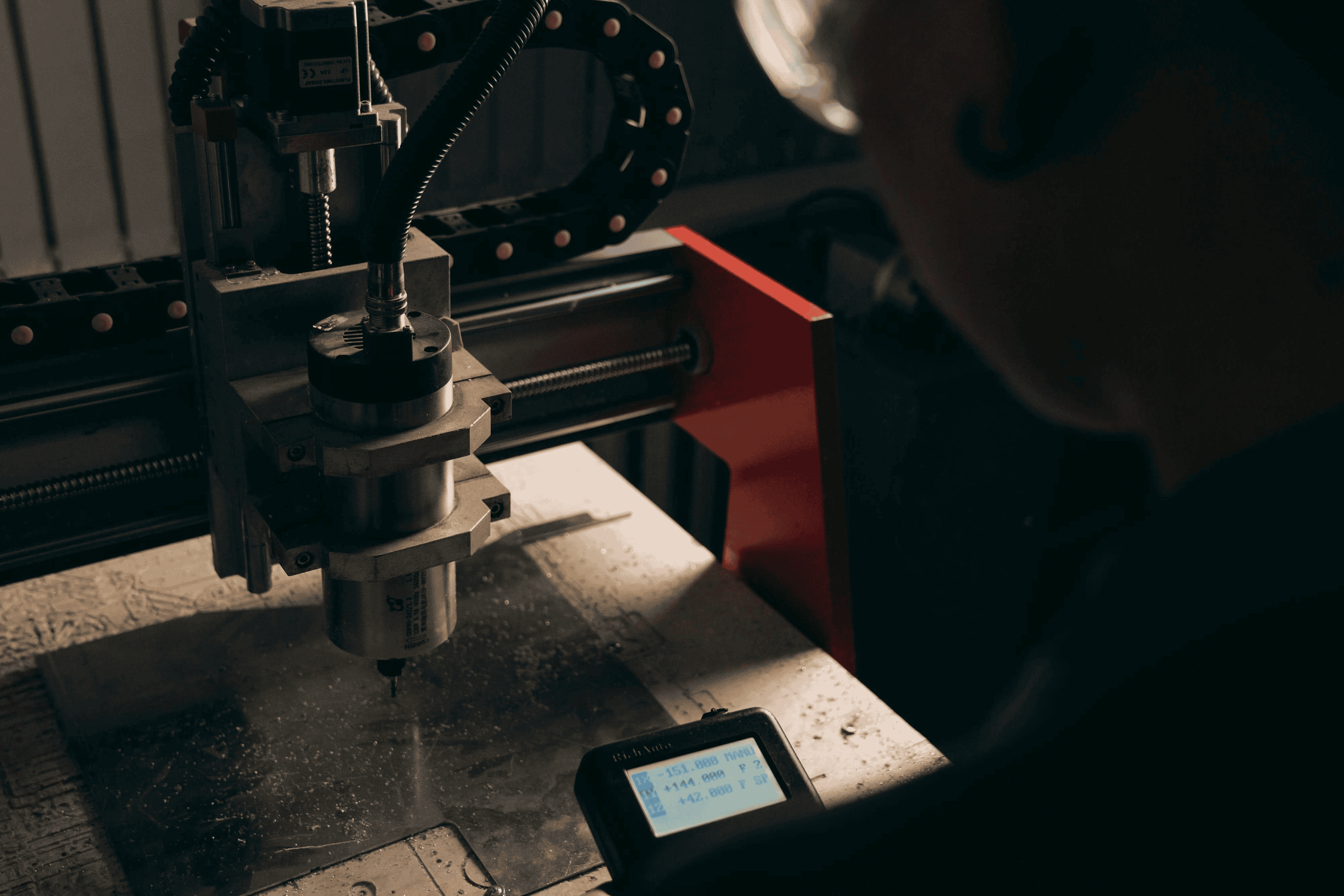

Custom Fabrication

Metal machining services span a family of subtractive processes that shape raw stock into accurate components. Core methods include milling for prismatic geometry, turning for round features, drilling and tapping for threaded holes, and grinding for tight surface finishes. Advanced shops also use electrical discharge machining for hard metals and intricate internal corners. The right mix is selected by tolerance targets, surface finish, material hardness, and production volume.

Precision depends on more than the machine. Workholding must resist vibration, chip evacuation must stay consistent, and thermal growth must be controlled so the last part matches the first. Toolpath strategies vary by feature type. A rigid roughing pass removes bulk material, then finishing passes dial in size and surface quality. Coolant delivery and tool coatings help manage heat and wear so edges stay crisp and dimensions stay stable.

Material choice drives outcomes. Aluminum machines quickly and offers good strength to weight. Stainless steel resists corrosion but work hardens if feeds and speeds are not balanced. Titanium needs rigid setups and conservative chip loads to avoid chatter. No matter the alloy, success comes from stable fixturing, sharp tools, and a repeatable inspection plan.

Metal machining services and cnc plastic milling services at OZK Customs in Fayetteville Arkansas.

cnc plastic milling services and broader cnc plastic machining services follow the same fundamentals as metal work but with very different priorities. Most plastics have lower melting points and higher thermal expansion, so heat management is the first concern. Sharp uncoated tools, light stepovers, and generous chip loads help cut cleanly without rubbing. Air blast or mist can cool the cut while avoiding fluid that might stress crack certain polymers.

Not all plastics behave alike. Acetal machines cleanly and holds tight tolerances. ABS is friendly but can string if chips are not cleared. Acrylic needs polished cutters and careful entry to prevent crazing. UHMW and HDPE are tough yet flexible, which challenges flatness. High performance options like PEEK demand rigid setups and accurate temperature control to maintain size. Selecting the right cutter geometry and edge prep prevents burrs and delivers a consistent finish.

Fixturing strategy changes with polymers. A broad support surface prevents creep and bow. Vacuum fixtures help hold large sheets without clamp marks. Soft jaws spread clamping force and reduce imprinting. When threads are needed, metal inserts or formed threads often outperform cut threads by reducing risk of stress cracking. Annealing before or after machining can relieve internal stress for dimensionally stable parts.

Use razor sharp end mills with polished flutes to move chips out quickly. Lower spindle heat, moderate feed, and higher chip load than a rubbing cut will produce tight, glossy edges. Stepdown and stepover should be conservative to prevent deflection, with finishing passes that only skim material.

Support the entire workpiece where possible and avoid point loads. Add sacrificial layers to protect surfaces. For thin panels or covers, vacuum tables provide even holding force and reduce warp during contouring.

Surface gloss depends on cutter polish and final pass strategy. For tight holes, reaming and boring deliver better size control than a single drill. Tolerance stacks should consider thermal expansion, especially for parts that will see temperature swings in the field.

Whether the job is ten parts or ten thousand, process control keeps variation low. Measure critical features in process, not just at final inspection. Use gage pins, bore gages, and surface checks to catch drift early. For metals, deburr without rolling edges. For plastics, avoid aggressive media that can roughen surfaces or embed grit.

Design choices ease machining and improve durability. Include generous internal radii to match cutter sizes. Avoid thin walls that flex under clamping. If a part mates to metal, plan for inserts or bushings to carry load. When you need optical clarity in acrylic or tight flatness in an ABS cover, coordinate finish passes and post processing early in the quote.

If your application mixes polymer and metal parts, a single source that understands both domains reduces fit issues. Tolerance decisions should reflect real function, not just a datapoint on a print. Document inspection criteria so every lot meets the same standard.

When it is time to move from concept to chips, a team that blends metal machining services with polymer know how makes the difference. Explore our custom fabrication to see how we approach complex assemblies and one off parts with the same discipline.

For engineered parts that pair aluminum frames with machined acetal panels or clear acrylic doors, our Fayetteville Arkansas shop can plan fixtures, set cutters, and validate critical fits. Review our fabrication services for a deeper look at processes, materials, and finishing options that keep projects on schedule.

Curious about process, communication, and support from kickoff to handoff Read why choose OZK to understand how we plan builds, share progress, and deliver parts ready to install.

custom fabrication fabrication services why choose OZKWe're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a drawing into a part that fits first time Every day we deliver precise metal and plastic components with smart fixturing, clean edges, and dependable tolerances. Tell us what you need, and our Fayetteville Arkansas team will quote, schedule, and machine your parts with transparent updates. Submit the form to get a fast, accurate estimate.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com