Custom Fabrication

Architectural metal cladding gives designers a crisp, repeatable surface with tight tolerances and a modern profile. It spans long runs, handles complex geometries, and offers a deep library of colors and textures that range from matte to high gloss to weathered looks. Paired with a ventilated cavity and continuous insulation, it creates a durable rainscreen that manages water and vapor while protecting the air barrier. Because panels are modular, crews can replace damaged sections without disturbing the entire facade. In commercial and industrial siding, this combination of precision, speed, and serviceability is hard to beat.

Profile selection drives both the look and the physics of a wall. Vertical metal siding panels shed water quickly, reduce horizontal ledge buildup, and visually stretch the building for a taller appearance. Common choices include standing seam, flush reveal, and ribbed profiles with either concealed or exposed fasteners. Commercial vertical metal siding often uses concealed fastening for a clean line and better control of water entry points. Panel width, rib spacing, and reveal depth influence light and shadow, so mockups are essential before you lock the specification.

A cladding system is only as good as the layers behind it. Start with a continuous air and water barrier, then add rigid insulation and a drained cavity sized for climate and exposure. Architectural metal cladding expands and contracts with temperature swings, so allow for movement at joints and terminations. In coastal or industrial environments, consider aluminum or stainless and specify high performance coatings for commercial metal siding panels. Fire and wind ratings must match the project’s risk category and local code, and fastener schedules should reflect calculated wind pressures, not just generic tables.

Upfront, commercial siding panels can price above some fiber or cement options, yet lifecycle economics often balance the ledger. Commercial steel siding delivers strength and impact resistance in loading zones and at grade, while aluminum saves weight at upper levels and reduces structural demands. Industrial metal siding tolerates forklifts, equipment scuffs, and repetitive wash downs where hygiene and durability matter. Maintenance typically consists of periodic cleaning and inspection of seams, sealants, and flashings, with panel level replacement when needed.

Success comes down to edges and penetrations. Focus on base of wall terminations with vented flashings that keep pests out and airflow moving. At openings, coordinate head, jamb, and sill flashings with the air barrier and define clear sequencing for the trades. Corners can be mitered, nested, or feature bespoke trims that align with panel reveals. Roof to wall and parapet transitions must control water while allowing for thermal movement. For commercial metal siding and industrial metal siding, specify gauges and sub framing that meet wind, impact, and deflection criteria without excessive fastener density.

Material selection should be project specific. Commercial steel siding is rugged and cost effective for distribution centers and school additions. Aluminum resists corrosion and is well suited for coastal projects and complex curve work. Stainless shines in aggressive environments that see chemicals or constant moisture. Finish systems like PVDF meet color retention targets and resist chalking, while textured embossing can reduce oil canning and add tactile interest to vertical metal siding.

Attachment strategies affect both schedule and performance. Z girts or thermal clips allow continuous insulation while anchoring commercial siding panels. Concealed fastener systems protect connections from weather and provide a refined look, while exposed fastener profiles can be economical for back of house elevations in industrial siding. Coordinate shop drawings so panel joints align with control joints, window lines, and expansion breaks. With careful layout, vertical metal siding can frame entrances, daylight zones, and signage bands with the precision of a millwork package.

Acoustics and interior comfort are easier to manage than most expect. The ventilated cavity of architectural metal cladding helps dissipate rain noise, and insulation layers control sound transmission. In mixed use properties, adding mineral wool behind commercial metal siding panels improves fire resistance and acoustic dampening in one move. Do not forget access provisions for future signage, lighting, and security devices; planned attachment points avoid messy retrofits later.

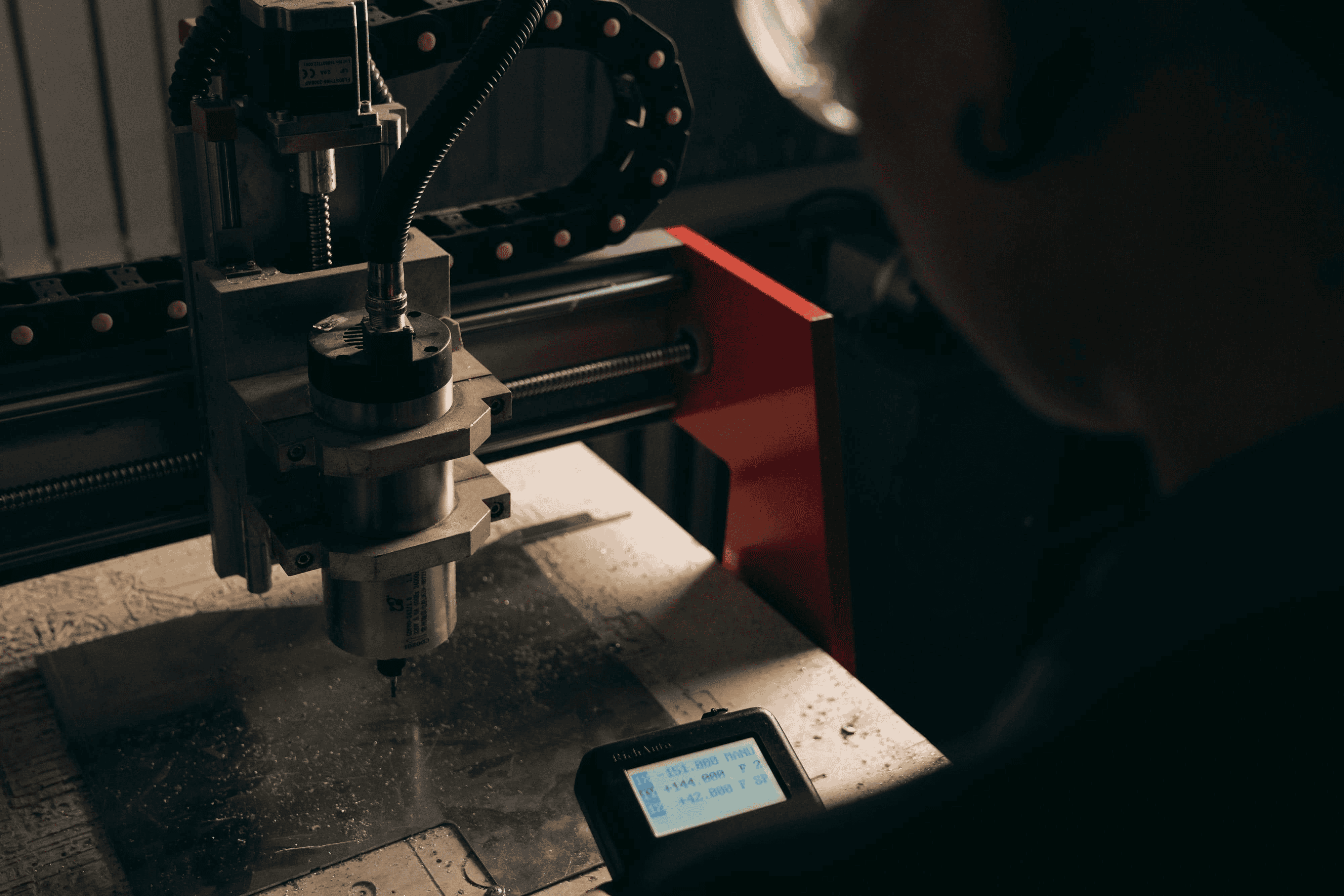

When your drawings are ready for takeoff, partner with a shop that can translate the detail into clean parts, accurate trims, and labeled kits. OZK Customs delivers design assist, shop drawings, and precise fabrication for architectural metal cladding, including vertical metal siding panels, corner closures, and custom flashings. Explore our custom fabrication to see how we handle complex profiles, specialty metals, and high finish standards built for commercial work.

If your project needs specialty brackets, sub framing, or one off profiles, our team can produce them quickly and ensure they fit the field conditions you face. Review our fabrication services to align scope and timelines early in preconstruction. Want to understand our process and track record before you award. Start with why choose OZK Customs for a look at our ethos, quality checks, and client experience.

OZK Customs is based in Fayetteville Arkansas and serves teams across the country. Bring us your section details and elevations for commercial vertical metal siding or industrial metal siding, and we will turn them into a build ready package that installs fast and looks right for years.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to move from spec to shop drawings to finished facade. OZK Customs fabricates custom metal cladding, trims, and attachment solutions that install clean and perform for decades. Tell us about your project and get a pricing path along with a build schedule.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com