Custom Fabrication

Metal laser cutting services and custom sheet metal fabrication for precision custom cut metals by OZK Customs

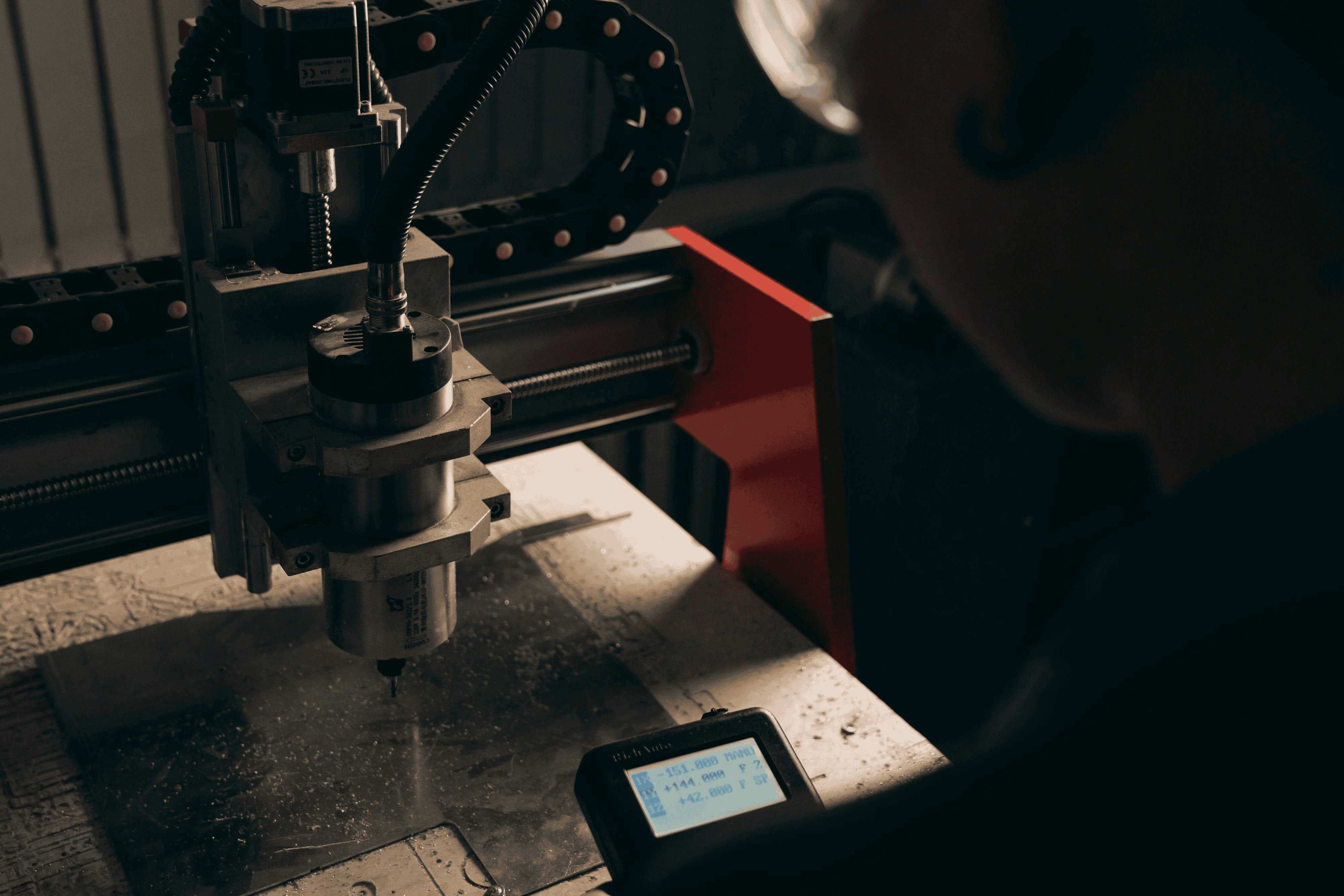

Metal laser cutting services center on directing a concentrated beam through metal to produce accurate profiles with repeatable tolerances. Fiber lasers excel at speed and edge quality on steel sheet fabrication and aluminum sheet fabrication, while also handling stainless with nitrogen assist for oxide free edges. Compared with waterjet and mechanical processes, laser cutting typically delivers a smaller kerf, a narrow heat affected zone, and superior throughput for custom cut sheet metal in thin to medium gauges.

Edge quality and tolerance depend on material, thickness, and setup. Thinner material allows faster feeds, tighter radii, and finer features for custom cut metal shapes. Thicker plate may require assist gas adjustments or multiple passes to keep cut integrity consistent. When choosing where to get metal cut, ask about cutting parameters, nesting software, and how the shop holds flatness after heat input, especially for custom cut steel plate or aluminum sheet metal fabrication.

Beyond cutting, sheet metal fabrication transforms flat stock into functional geometry. Press brakes achieve metal forming services like bends, hems, and jogs with controlled radii. Hardware insertion adds studs and standoffs. Welding unites assemblies for custom metal parts manufacturing, and post processing sets the look and performance. A capable sheet metal workshop moves seamlessly from laser programs to brakes, fixtures, weld cells, and finishing lines.

Laser is usually faster for custom sheet metal and delivers crisp edges, ideal for tight tab and slot features and sheet metal parts that will be formed later. Waterjet has no heat affected zone and can process thick or exotic materials, but it generally runs slower. For most custom metal fabrication prototype runs in common alloys, laser hits the sweet spot of speed, cost, and precision.

Expect typical laser tolerances in the low thousandths on thin gauges, loosening as thickness rises. Kerf width ranges by nozzle, lens, and material; tightly nested custom cut steel sheet benefits from consistent kerf compensation to maintain fit. Edge quality improves with clean optics, proper assist gas, and tuned parameters, which reduces secondary cleanup before custom metal part finishing.

Mild steel, stainless steel, and aluminum dominate custom metal manufacturing. Steel fabrication services cover hot rolled, cold rolled, and coated sheets. Aluminum custom fabrication often uses 5052 for forming and 6061 for structural pieces. Confirm your target bend radius and K factor during design so parts form accurately after cutting in sheetmetal fabrication.

A complete workflow for custom metal work usually begins with DFM feedback, then moves to programming, cutting, forming, and assembly. During sheet processing services, nesting software optimizes material yield, and labels track each component through the sheet metal machining and forming steps. After the laser, parts go to the press brake for metal forming services, where bend order and tooling selection protect surface finish and control springback on custom size sheet metal.

Secondary operations can include tapping, countersinking, and hardware installation for custom sheet metal fab. Welders use MIG or TIG depending on material and joint design, producing clean seams on custom metal pieces. Finishing options range from tumbling and graining to powder coat and anodize, all part of comprehensive fabrication services that tie performance to aesthetics. Proper deburring and edge break reduce injury risk and improve coating adhesion, a key step before custom metal part finishing.

For repeatability, choose datum features that survive the entire process, especially when post weld machining is required. If your product requires tight assembly, specify critical to quality dimensions and use gauges at inspection. Whether you are building a single custom metal fabrication prototype or a production run of custom metal parts, consistent checks keep results predictable.

Selecting custom sheet metal fabricators that make custom parts comes down to capability, capacity, and communication. Ask for examples that match your material and thickness, such as aluminum sheet metal fabrication for enclosures or steel plate cutting services near me for heavy brackets. Confirm the shop can hold your tolerances after forming and welding, not just at the cut table. Look for transparent lead times and process control from quote to shipment.

If your design is not final, request bend test coupons and a forming review. Provide flat patterns in DXF plus a STEP model for assemblies, and include bend lines, radii, and grain direction notes. Small changes like larger hole to edge distances or reliefs at corners can make custom sheet metal easier to form and help avoid cracking, especially in aluminum custom fabrication. When you need custom cut aluminum, custom cut steel, or mixed material builds, combine clear drawings with practical tolerances to balance cost and performance.

When buyers search phrases like where to get metal cut or custom cut steel sheet, they are seeking reliability more than anything. A quality focused shop will manage raw materials, traceability, and packaging so your sheet metal parts arrive flat, clean, and labeled. That same team should guide coatings and textures to match your environment, from salt spray resistant powder to anodized finishes.

We build that experience into every project. For complex brackets, racks, or vehicle components, our team handles laser cutting, bends, welds, hardware, and coatings under one roof, so your custom metal manufacturing stays on schedule. See our core capabilities in custom fabrication and explore the breadth of our fabrication services from CAD to finishing. Curious how we operate and what customers experience end to end? Learn more at why choose OZK Customs.

Ship us your prints and let us translate them into custom cut metals that form, fit, and finish as intended. Whether you need custom cut metal shapes for a pilot build or a scaled batch of steel sheet fabrication, we can produce, inspect, and package your order so it is ready to assemble on arrival.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a drawing into durable parts? Tell us your material, thickness, quantity, and finish goals. OZK Customs will quote quickly, engineer smartly, and deliver custom metal pieces that fit first time.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com