Custom Fabrication

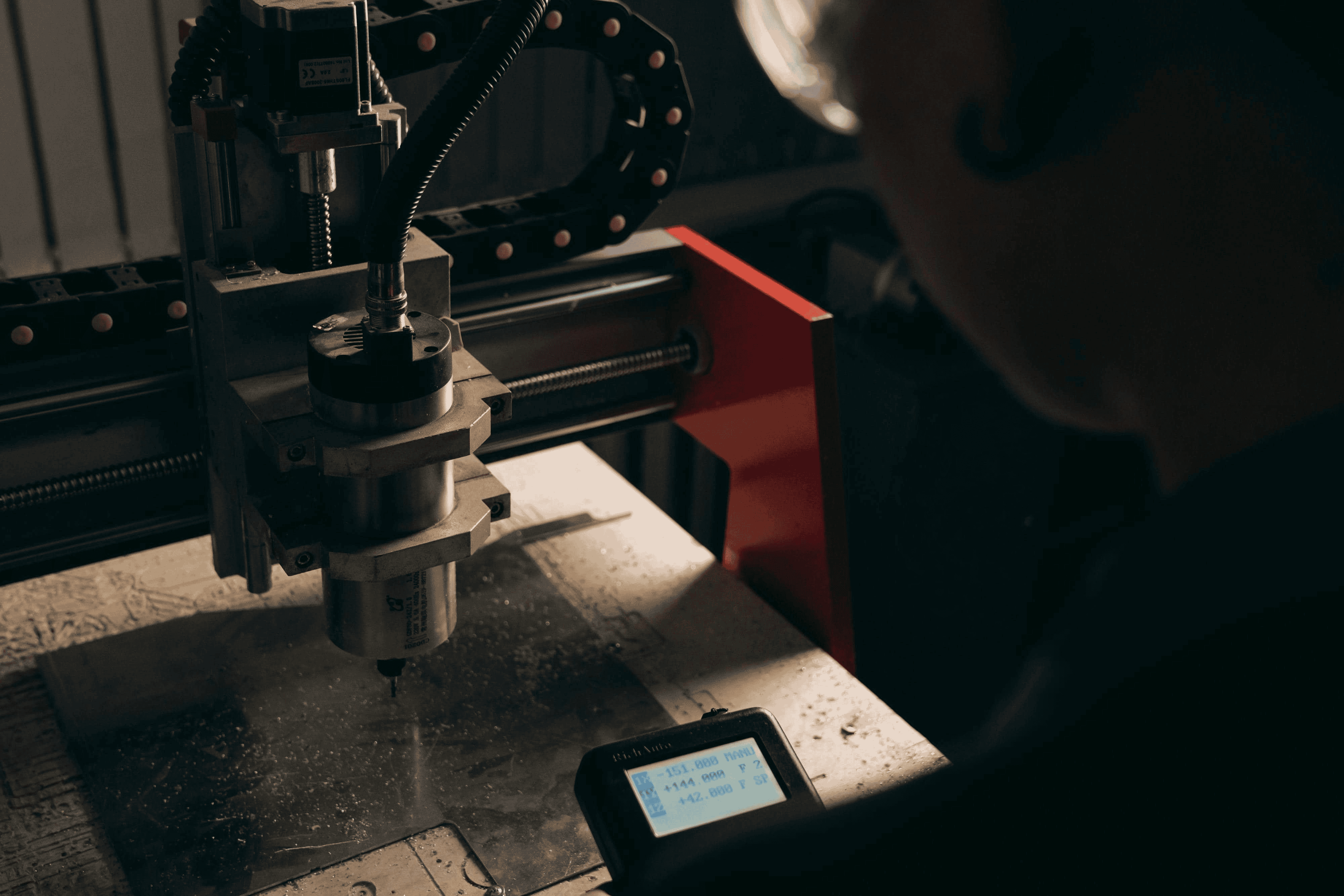

Metal machining services transform raw stock into accurate forms using cutting tools, motion control, and workholding. At the core are cnc machining services that split into cnc milling services for prismatic features and cnc turning services for cylindrical geometry. Many cnc manufacturing shops add grinding, broaching, threading, and deburring to deliver complete cnc machining parts that are ready for assembly.

Precision machining service depends on three pillars: process capability, tooling strategy, and inspection. Shops tune feeds, speeds, and coolant to match alloys. They choose end mills, drills, or inserts for tool life and surface finish. They validate results with calibrated inspection, often combining in process checks with final reports. The result is custom made machined parts that meet function, fit, and finish goals.

Metal machining services and CNC machining parts for custom precision components in Fayetteville Arkansas

Milling removes material with rotating tools while the part stays fixed. Turning spins the workpiece and brings tools into contact. Three to five axis platforms drive toolpaths that define complexity, cost, and speed. For many parts, 3 axis machining services cover flat planes, pockets, holes, and bosses with excellent repeatability. When undercuts or compound angles appear, multi axis strategies reduce setups and improve accuracy.

Tight tolerances demand planning. CNC close tolerance machining services often hold features within a few thousandths when geometry, material, and tool reach align. Heat can shift small parts during heavy cuts, so rough then finish passes stabilize size. Custom precision machining also accounts for runout, workholding clamping pressure, and probe offsets. Clear drawings with datum schemes and GD and T help cnc shops quote reliably.

Material selection shapes success. Aluminum machines quickly and suits rapid cnc machining. Stainless resists corrosion but work hardens, so tooling and coolant matter. Tool steels need rigid workholding. Copper alloys evacuate heat differently and can smear. The chosen finish also affects cost and schedule. As machined, bead blast, anodize, passivate, and plating change performance and appearance while adding operations to the routing.

CNC lathe machines for custom parts excel at shafts, bushings, pins, and threaded features. Add live tooling and you can mill flats, keyways, and cross holes in one setup. On the milling side, high speed strategies maintain chip thinning and consistent engagement, creating smooth walls and stable tool life. For simple brackets and plates, cnc cutting machines for custom parts deliver clean edges and repeatable holes.

CNC prototyping validates geometry, assembly stack ups, and fastener access before scaling. Rapid cnc services balance speed with adequate tolerance, making it easier to test and revise. Once validated, batch production locks fixtures and tool libraries, then tunes cycle times. When volumes climb, cnc secondary machining services handle deburring, tumbling, tapping, and marking to keep lines moving.

Quality blends measurement and documentation. Shops use digital calipers, micrometers, height gages, and coordinate measuring machines to verify critical features. Secondary ops like heat treat and coating shift dimensions, so allowance is built into the model or drawing. A strong precision machining service anticipates these shifts and plans compensation so final parts meet the print.

Sourcing starts with a clean model, readable drawings, and clear notes. Provide tolerances only where function requires them. Call out threads, edge breaks, and finish requirements. Ask for a cnc quote online from two or three vetted suppliers rather than many, to keep focus on quality. Many platforms now provide online machining quotes that compare price and lead time. Search results for cnc machine online and online cnc service can help you find suppliers, but vet capability through portfolios, certifications, and references.

Price is only one metric. Cheap cnc machining can cost more through scrap, delays, or rework. The best online cnc service or best online machine shop couples transparent pricing with engineering feedback, material traceability, and reliable packaging. When you evaluate cnc shops, look for responsive communication, sample inspection reports, and clear commitments on tolerances and finishes. If your builds are domestic or export controlled, confirm cnc machining usa capability and compliance.

Ongoing programs benefit from clear revision control and stable workholding strategies. When volumes repeat, fixture investment pays back quickly. For custom cnc parts that change frequently, modular fixtures and soft jaws keep setups flexible. Over time, long term relationships with cnc services mean better DFM suggestions and fewer surprises.

To integrate machined parts into larger assemblies, coordinate holes, slot locations, and thicknesses with mating components. When welding or forming follows, align tolerances so downstream work remains efficient. This is where fabrication and machining must work as one. If you need support aligning those steps, explore our custom fabrication approach for design and build continuity.

We regularly design brackets, mounts, and structural elements that pair machined interfaces with fabricated bodies. If your project requires plasma cut blanks, formed panels, and critical machined bores, you can see fabrication services that bridge cutting, forming, and finishing. For customers comparing partners, learn how we prioritize communication, documentation, and fit up on why choose OZK Customs.

By blending practical machining knowledge with fabrication experience, we help you move from concept to parts without friction. Whether you need rapid cnc machining for a prototype bracket or custom machining services for a production run, our team can scope the work, prepare revisions, and coordinate with proven suppliers. That means your project keeps momentum while protecting quality at every step.

Your parts should fit first time and stand up to use. Share your model and requirements, and we will guide materials, tolerances, finishes, and the right path through machining and fabrication. Start with our custom fabrication page, review the fabrication services we offer, and see why choose OZK Customs to understand how we deliver. From brackets and mounts to structural interfaces and precision inserts, we turn ideas into parts that work.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn drawings into durable parts and finished assemblies? OZK Customs integrates CAD design, custom metal fabrication, and precision machining coordination to deliver components that fit and function in the real world. Share your prints and priorities, and our team will guide materials, tolerances, and finishes, then manage machining and fabrication through to installation. Start your project today and get expert help from a shop that builds for adventure and performance.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com