Custom Fabrication

Typing welding shop near me usually means you need skilled hands on a specific metal job within driving distance. It might be a cracked aluminum bracket, a stainless tank modification, a steel bumper repair, or a custom fixture to speed up production. A strong shop pairs process know how with clean fit up, correct filler, and consistent heat control. That is how you get welds that hold up, look clean, and pass inspection.

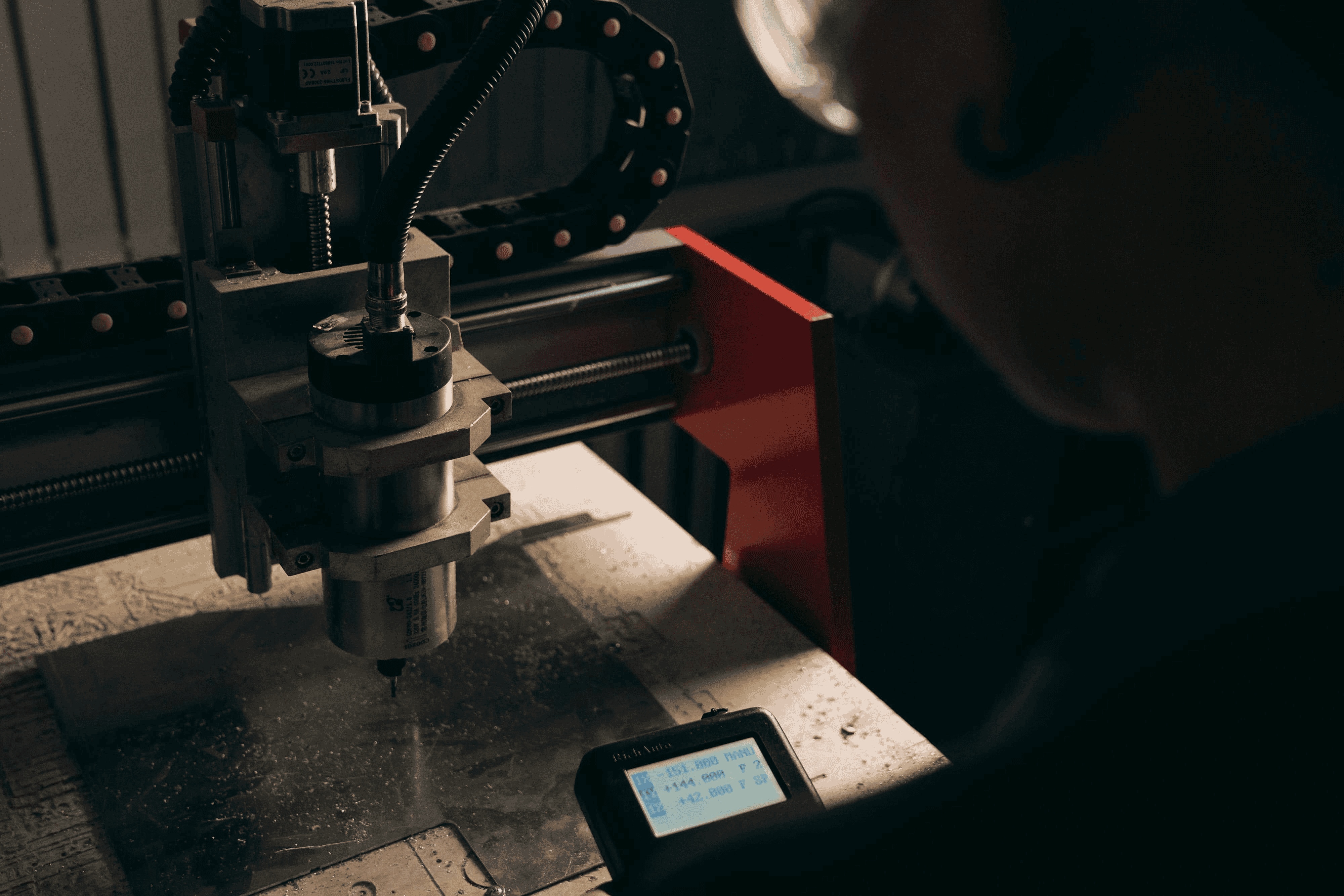

Custom welding near me at OZK Customs in Fayetteville Arkansas, precision TIG and MIG welding on steel aluminum and stainless for vehicles and fabrication projects

When you evaluate options, focus on process fit. TIG excels at thin gauge aluminum and stainless where appearance and precision matter. MIG is fast and efficient for many steel assemblies. Stick is common for field repairs and heavy plate. The right process is only part of the story. Fixturing, joint prep, and post weld finishing often determine whether your part fits, performs, and lasts.

Shops should state their comfort with steel, stainless, and aluminum, plus thickness ranges. Ask how they prevent distortion on long seams and whether they use back purging for stainless. Precision jobs require jigs or modular fixtures, careful tack sequencing, and measurement tools to keep flatness and squareness within spec. Expect clear discussion of tolerances, not just a verbal yes.

Quality control starts before the arc strikes. Good shops define joint geometry, bevels, root gaps, and clamp strategy. After welding, they may use visual inspection, dye penetrant for surface cracks, and bend or macro tests for procedure validation. For assemblies, functional checks and test fits help verify alignment before coating. Request photos or sample parts to see finish quality and consistency.

Finding custom welding near me or custom welding shops near me is only step one. The real work is aligning capability with your scope. Certifications matter when structural integrity or code compliance is involved. Ask about written procedures, approved filler metals, and shielding gas choices. Shops that document their approach usually deliver more predictable results.

Time and budget are also critical. Lead times are influenced by design clarity, material availability, and the number of heat cycles needed. Aluminum jobs may require more prep and post clean up. Complex stainless work benefits from purging and careful heat input, which adds hours but protects corrosion resistance. A transparent quote will itemize those steps so you understand cost drivers.

Visiting a shop in person helps. Look for clean prep areas, organized filler storage, and dedicated aluminum tools to avoid cross contamination. Observe how parts are staged and identified. Ask to see examples that resemble your project. The best predictor of success is a proven track record on similar work.

If you are in Northwest Arkansas, pairing local know how with strong fabrication capability shortens the path from idea to install. In Fayetteville Arkansas you can streamline projects by combining design support, fixturing, and precision welding under one roof. That is especially useful for vehicle integrations, off grid systems, and custom brackets where fit, strength, and appearance all matter.

OZK Customs builds adventure vehicles and fabricates the metal that makes them durable. Our team handles TIG on aluminum and stainless, MIG on steel, and the fixturing that keeps parts straight and true. Explore our custom fabrication to see how welding connects with cutting, forming, and finishing. For detailed capabilities, lead times, and materials we work with, review our fabrication services. Want to understand our approach and client experience before you book? Start with why choose OZK.

Whether you need a stainless tank modification, an aluminum roof rack mount, or a steel bumper repair, we will help map the right process and sequence for clean, strong results. Bring your drawings, photos, or a sample part. We will review tolerances, plan fixturing, and set a clear schedule that respects your timeline in Fayetteville and across Northwest Arkansas.

Make the search for a welding shop near me count. Share your project goals and constraints, and we will turn them into weld ready plans and a finished part that fits the first time.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to stop searching and start building? Tell us about your project and timeline. Our Fayetteville team will review your drawings, confirm materials and finishes, and deliver a clear plan with pricing. From precision TIG work to full vehicle integrations, OZK Customs turns ideas into road ready hardware.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com