Custom Fabrication

When people search for metal fabricators near me or fabrication work near me, they are usually balancing speed, price, and accuracy. The best fit depends on how complex your part is, which materials are involved, and how tightly you need to hold tolerances. Start by aligning the scope of your job with a shop’s core services. If your parts require CNC cutting, forming, precision fixturing, and clean welds, verify that the shop does those steps in house and not through a chain of subcontractors that can add risk.

Material expertise matters. Mild steel, stainless steel, and aluminum behave very differently during cutting and welding. Aluminum demands exceptional cleanliness and heat control. Stainless can distort if heat input is not managed. Ask about process controls, such as weld procedures, purge setups for stainless, and dedicated tools to avoid cross contamination.

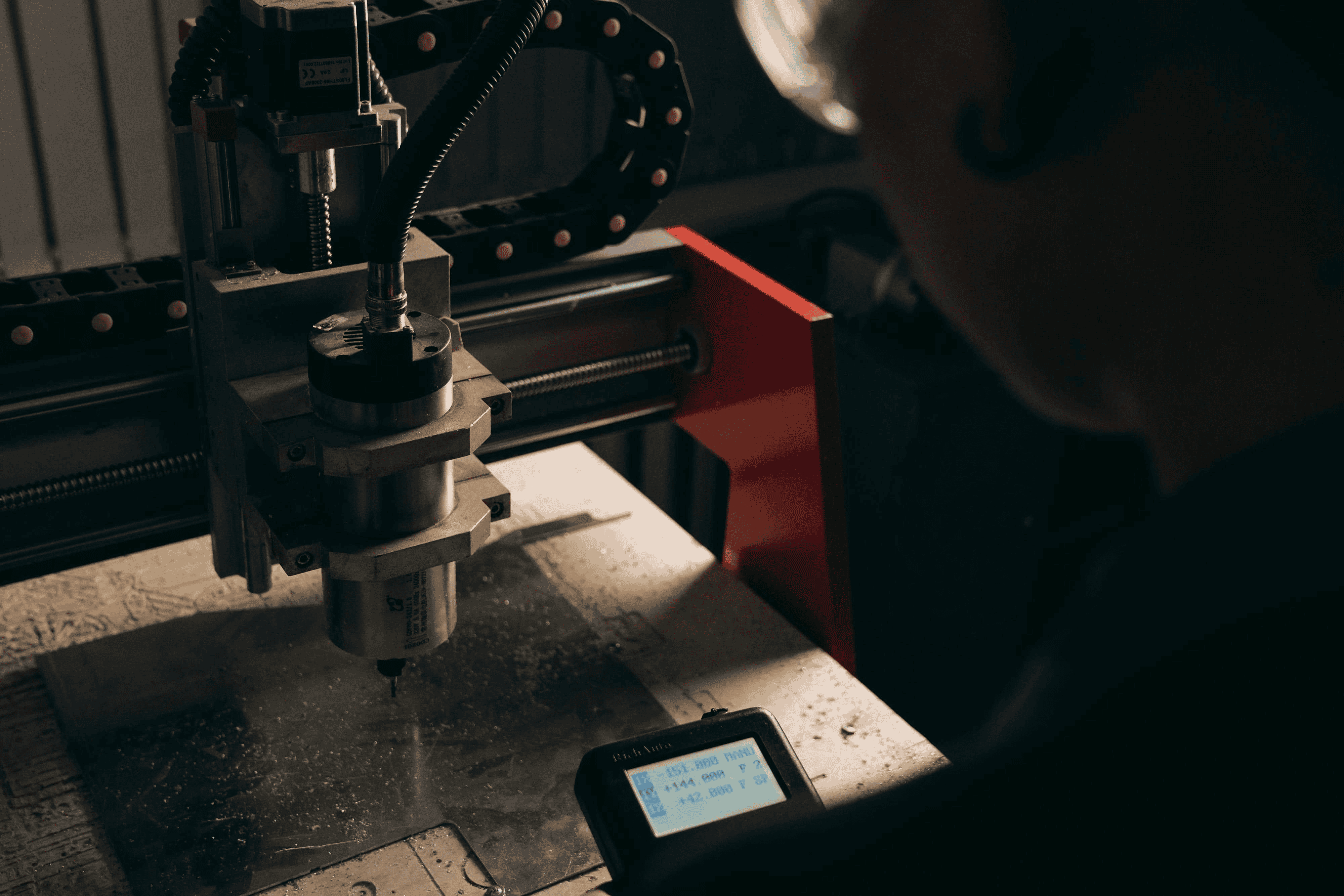

Cutting methods drive both edge quality and cost. Laser and waterjet produce crisp edges and fine features. Modern plasma is efficient for thicker plate. For tight assemblies, confirm the shop can hold the tolerances your drawings call out and can deburr and finish edges consistently. Request sample parts or a short run to validate real world capability.

Certification is a fast proxy for quality. Look for documented weld procedures, inspector sign off, and material traceability when required. Shops that measure before and after welding, and that record tolerances on a control plan, help reduce surprises during assembly. A repeatable quoting process that lists assumptions, materials, finishes, and delivery also signals mature operations.

Aluminum custom fabrication rewards careful technique. Alloys like 6061 and 5052 are common. Each responds differently to forming and welding. Joint design must allow for thermal expansion and shrinkage. Cleanliness is critical. Any oxide or oil interferes with weld puddle control, so proper surface prep is a must. Many aluminum projects rely on AC TIG for precise control or pulse MIG for productivity with good appearance.

Fixturing is the unsung hero. Rigid fixtures limit movement and allow the fabricator to balance heat input across the part. If your assembly includes tapped holes or inserts, discuss thread strategy, grip lengths, and galvanic isolation when mating aluminum to stainless or carbon steel. Finishing steps can include sanding to a uniform grain, glass bead for texture, or powder coat for durability. For high visibility parts, define the surface finish up front to avoid mismatched sheen across panels.

Specify finishes based on environment and wear. Powder coat offers impact resistance. Anodizing can improve corrosion resistance and provides color choices, though not all alloys anodize identically. For assemblies, consider masking, hardware selection, and touch point protection during shipping so the delivered surface looks like the sample.

Local metal fabrication shops bring speed and easier collaboration. You can review parts on site, iterate quickly, and reduce freight costs. Small metal fabricators near me often excel at prototypes, short runs, and repairs that need creative problem solving. Larger regional shops can be ideal for multi process jobs, higher volumes, or complex assemblies that require coordinated machining, forming, and certified welding.

Balance convenience with capability. For simple brackets and guards, a nearby job shop may be perfect. For assemblies with tight flatness and cosmetic requirements, ask whether the shop uses flatness checks after powder, and whether they stress relieve or sequence welds to control movement. Lead time is a function of complexity, material availability, and finishing. Build in time for first article approval, especially if tolerances are demanding.

With these details, you will receive comparable quotes and avoid hidden costs later.

If you want a partner who can translate drawings into metal with minimal back and forth, consider a regional expert anchored in Fayetteville Arkansas and serving Northwest Arkansas. Our team at OZK Customs builds functional parts for vehicles and purpose built equipment, and we do it with the same care we put into our custom rigs. Explore our Custom fabrication to see how we handle aluminum panels, brackets, racks, and structural components. Review our full list of Fabrication services if your project needs CNC routing, plasma cutting, precision welding, and clean finishing.

Choosing between local metal fabrication shops and broader options does not have to be a gamble. If your search for metal fabricators near me or aluminum custom fabrication brought you here, we are ready to help. Learn more about our approach and customer experience at Why choose OZK Customs. Tell us what you are building, where it will live, and how it will be used. We will return a clear plan, a confident timeline, and a result that fits the first time.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a sketch into metal? Tell us about your timeline, material, and finish needs. OZK Customs will quote fast, build precisely, and deliver a shop floor ready result that fits first time.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com