Custom Fabrication

Architectural metal cladding serves as a protective skin that controls water, air, and heat, while providing a crisp, contemporary look. Most assemblies function as ventilated rainscreens: a drained cavity sits behind the exterior layer, allowing incidental moisture to escape and letting the wall dry. This approach improves durability and simplifies maintenance compared to face sealed systems.

Base metals include aluminum, galvanized or stainless steel, zinc, and copper. Aluminum is light, corrosion resistant, and easy to form. Steel offers strength and impact resistance. Zinc and copper add a living patina that evolves over time. Panel thickness, temper, and alloy influence stiffness, flatness, and fabrication methods. Finishes range from high performance fluoropolymer coatings that meet AAMA 2605, to anodized layers for metallic depth, to durable powder coats with textured effects.

Attachment strategies define the visual language and performance. Concealed fastener systems use clips or rails to hold cassettes or interlocking profiles, emphasizing clean lines. Exposed fastener corrugated and ribbed profiles deliver a bolder industrial expression and can be efficient on large elevations. Joint geometry manages thermal movement, wind loads, and rain entry. Pressure equalized joints can reduce water drive by balancing air pressure within the cavity.

Thermal and moisture control are central to success. Continuous insulation outboard of the sheathing reduces thermal bridging, while ventilated cavities promote drying. Thermally broken brackets and girts limit heat loss across the subframing. Proper sequencing of air barrier, flashing, and weeps ensures that any water that gets in can always get out. In coastal or industrial zones, detailing for corrosion control and regular wash downs further extend service life.

Fire and code compliance depend on assembly testing rather than just the cladding itself. Many wall systems must meet NFPA 285 for multi story use, with mineral wool often chosen for its noncombustible rating. Wind and seismic design follow structural criteria such as ASCE 7, with panel span, gauge, and fastening pattern engineered accordingly. Acoustic targets, impact resistance, and blast or ballistic needs can also shape the specification in mission critical facilities.

Sustainability considerations include recycled content, Environmental Product Declarations, and long service life with minimal maintenance. Disassembly friendly designs support reuse and reduce waste at end of life. Specifiers often prioritize finishes with long warranties, low maintenance cleaning, and colorfastness under intense sun.

The phrase facade panels cladding covers several families of products. Aluminum plate panels provide excellent flatness and sharp folds, often in the range of eighty thousandths of an inch for higher performance facades. Aluminum composite material, typically four or six millimeters thick, sandwiches a core between metal skins for stiffness at low weight. Single skin profiles, such as corrugated or standing seam, can span efficiently and bring texture to large surfaces.

Exterior facade panels are frequently configured as cassettes with formed returns that hook onto rails, or as interlocking planks with male and female edges that snap together. Open joint rainscreens introduce crisp shadow lines and allow pressure equalization, while closed joint designs use gaskets or battens for a tighter expression. Perforated and embossed panels add ventilation, shading, or a kinetic look that shifts with light.

Finish selection is about more than color. High performance PVDF coatings deliver long term color and gloss retention. Anodized aluminum produces a durable metallic appearance with unique depth. Zinc and copper develop natural patinas that self heal fine scratches and blend elegantly over time. Fastener and trim color matching preserves the intended look from close range.

Corners, terminations, and penetrations require precise detailing. Returns must allow movement without oil canning, and subframing should land where it supports panel edges. Drip flashings, end dams, and back pans manage water at openings. Control joints handle building movement and wind induced panel shifts without stressing the system.

Joint width is a balancing act: wide enough to accommodate thermal expansion, tight enough to maintain the design rhythm. Ribbing, stiffeners, or thicker plate can improve flatness on large formats, while careful handling during fabrication and install prevents dents and waves.

Dissimilar metals can create galvanic reactions. Use isolators, compatible fasteners, and proper sealants to keep the assembly stable in marine or industrial environments. Routine cleaning avoids buildup that traps chlorides or grime.

Start with the wall as a system. The air barrier and flashing strategy set the foundation for a durable facade. Next, select subframing that supports continuous insulation and maintains ventilation behind the cladding. Thermally broken brackets reduce heat loss, and vertical and horizontal rails create a grid for efficient panel layout.

On site coordination is critical. Tolerances for substrates, alignment of rails, and verification of cavity depth all affect panel fit and finish. Shop drawings should lock in joint sizes, corner conditions, and fastener strategies before fabrication begins. Field mockups validate water management and installation sequence, and provide a visual benchmark for the finished product.

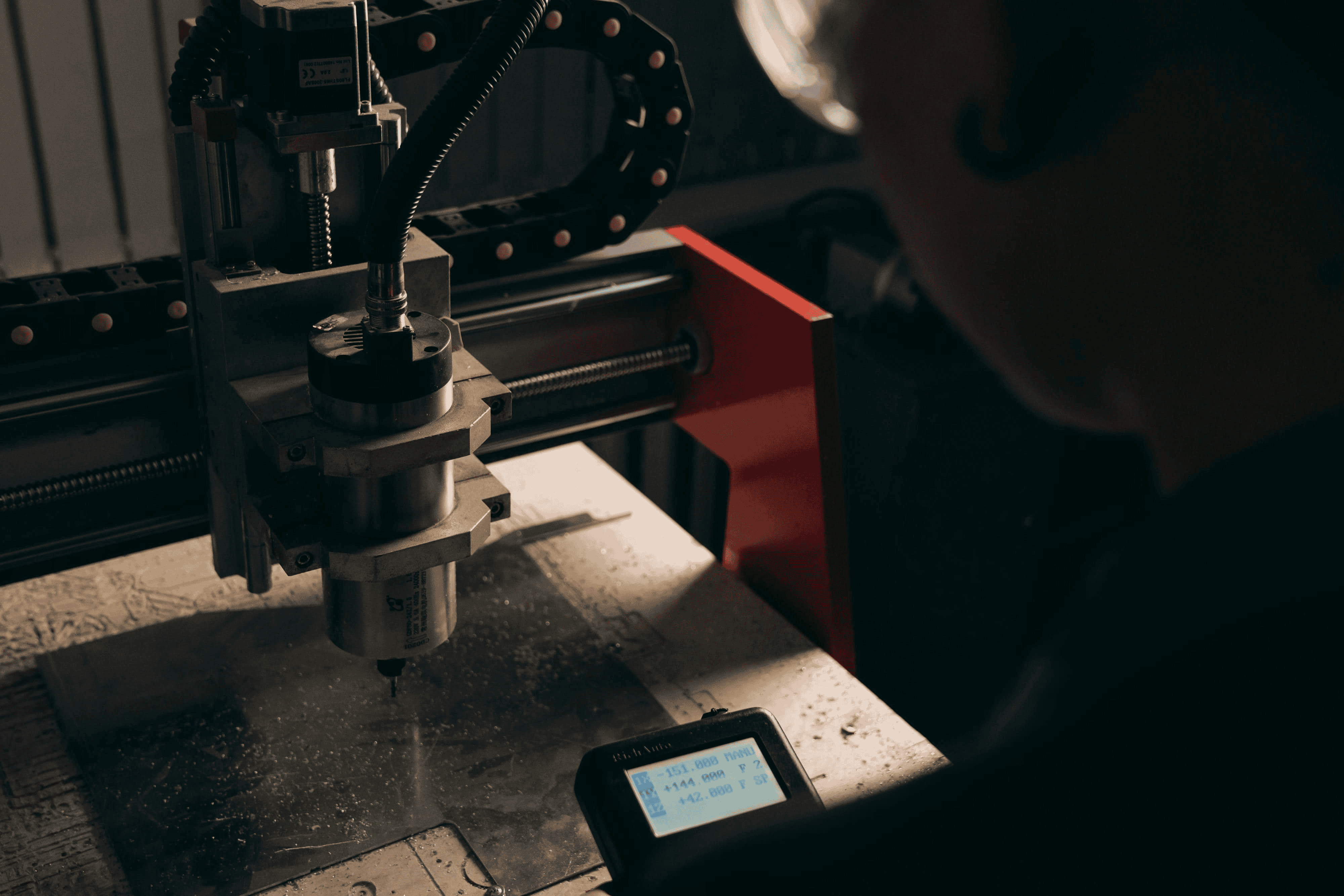

When it is time to move from concept to build, precise fabrication and documentation keep projects on schedule. OZK Customs builds to shop drawings, producing formed panels, trims, and subframing with tight tolerances and clear labeling. For complex corners or perforation patterns, our team collaborates on prototypes and mockups to confirm performance and appearance before full production.

If you need a partner to translate details into parts that install smoothly, explore our custom fabrication. For scope breakdowns and capabilities, see our fabrication services. Curious about our process and values from Fayetteville in Northwest Arkansas? Visit why choose OZK. We bring the same precision we apply to engineered vehicle platforms to architectural elements, with an emphasis on clarity, quality, and on time delivery.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a concept facade into precise, buildable metal? Our team designs, fabricates, and delivers panel systems, trims, and subframes with tight tolerances and clear documentation. Share your drawings and timeline, and let OZK Customs bring your exterior to life.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com