Custom Fabrication

Architectural metal cladding delivers crisp geometry, stable performance, and broad aesthetic range. It wraps a building with durable skins that can be ventilated or sealed, depending on climate strategy. When used as a rainscreen, cladding sits off the weather barrier to promote drainage and airflow, improving thermal performance and drying potential. The result is a facade that controls water, resists impact, and presents a modern language suited to both commercial and residential work.

Architectural metal cladding with flat metal siding panels on a modern facade in Fayetteville Arkansas

Material choices shape appearance and lifespan. Aluminum is lightweight and corrosion resistant, making it ideal for coastal or humid regions. Galvanized or galvalume steel brings strength at a competitive cost and receives paint systems well. Zinc and copper patinate gracefully, shifting color as they weather and providing a premium, living finish. Panel gauge affects stiffness and dent resistance, while factory coatings like PVDF lacquer resist UV fade and chalking.

Flat systems emphasize quiet planes and tight joints. Flat metal panels gain rigidity from hemmed edges, internal stiffeners, or joint geometry. Designers often use concealed fasteners to maintain uninterrupted lines, while open joint rainscreens rely on baffles and back pans to block driven rain. Detailing governs success: pressure equalization, flashing continuity, and breathable wraps must work together to keep the wall dry.

High performance coil coatings such as PVDF deliver excellent color retention and chemical resistance, crucial for sun baked facades. Polyesters are budget friendly but have shorter gloss retention. For coastal projects, aluminum or stainless fasteners and trimmed edges limit galvanic reactions. Clear coats or anodized finishes can highlight metal grain, while textured paints soften glare and reduce the perception of oil canning.

Flat metal siding panels create minimal, orderly fields that suit modern architecture. Layout starts with module planning: establish a base grid tied to window heads, sills, and corners so cut pieces are minimized. Flat metal siding can read as a monolithic plane or as a rhythm of reveals, depending on joint width and the use of contrasting trims. Corner strategies include folded corners for a monolithic look or prefabricated extrusions for rapid, repeatable installation.

Metal wall panel profiles dictate stiffness and visual character. Perfectly flat metal wall panels offer the cleanest look but require careful gauge selection, stiffeners, and fastener spacing. Shallow reveals or micro ribs can tune stiffness without changing the minimalist aesthetic. For residential projects, metal siding panels for house applications often pair flat fields with accent zones that use wider reveals or vertical joints to add scale.

Common joint approaches include interlocking edges, shiplap, and hook seam. Interlocking joints provide alignment and strength, while shiplap delivers simple weather shedding. Hook seams enable concealed clips that allow panels to float, helping manage thermal expansion without distorting lines. Joint sizing, typically between quarter inch and half inch, affects shadow pattern and tolerance absorption.

A sound assembly starts with a continuous weather resistant barrier, taped sheathing joints, and a ventilated cavity if using a rainscreen. Clips or concealed fasteners attach to girts or hat channels that create a drainage and pressure relief space. Thermal breaks at subframing reduce conductive losses through the wall. Flashing at windows, parapets, and base conditions ties the system together, directing water outward.

Thermal movement is central to performance. Metal expands with temperature swings, so panels need room to float. Slotted fastener holes, sliding clips, and movement joints at long runs prevent deformation. Oil canning, the slight waviness visible on sunlit surfaces, is mitigated through panel width control, thicker gauges, tension leveling, and ribbing strategies that do not compromise the flat aesthetic.

Routine maintenance is straightforward. Annual rinsing with clean water removes airborne contaminants, and gentle, pH neutral cleaners address stubborn buildup. Avoid abrasive pads that can mar finishes. Inspect fasteners and sealants at intervals, especially in high wind or coastal areas, and repair any damage promptly to protect cut edges and maintain finish warranties.

Plan for predictable expansion by locating fixed points near midspan and allowing movement toward edges. Keep fastener spacing consistent as specified by the manufacturer. Use compatible sealants and gaskets in joint areas where differential movement occurs, and ensure drainage paths remain open after thermal cycles.

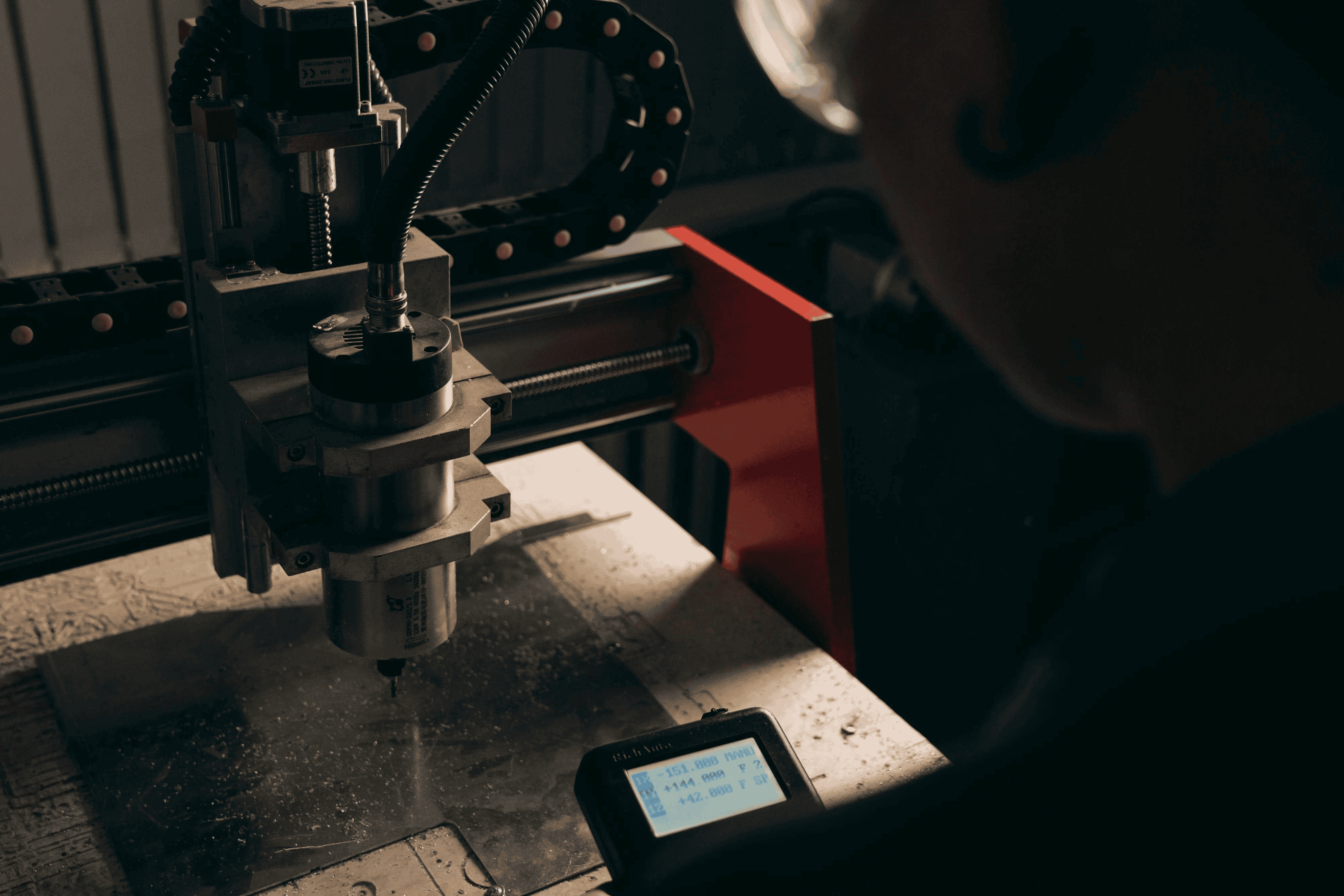

As projects move from concept to build, custom fabrication becomes the difference between crisp lines and fussy improvisation in the field. Precision formed trims, matched corners, and accurate panel modules keep seams true and reduce install time. If your design calls for bespoke reveals, custom cornices, or integrated vent details, explore our custom metal fabrication capabilities for exact, repeatable parts that meet spec.

Complex scopes often benefit from a partner who can engineer panel geometry, model tolerances, and prototype difficult transitions before jobsite work begins. See how our fabrication services bridge design and installation with CNC formed components, precise cut lists, and coordinated hardware that match your selected metal wall panel profiles.

Selecting a build partner is as much about process as it is about tools. Review our approach to quality, communication, and handoff on why choose OZK Customs to understand how we keep flat metal siding panels aligned, watertight, and true to the intended aesthetic.

Whether you are specifying flat metal siding, designing flat metal wall panels for a new facade, or refreshing a home with flat metal panels, clear shop drawings and precise fabrication set the tone for a smooth build. Share your drawings, desired joint expression, and finish schedule. We will help translate concept to real parts, then deliver clean installation that preserves the architectural intent from the first panel to the last.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn your concept into precise, durable metal cladding? Submit your drawings and goals. OZK Customs will engineer panel profiles, fabricate exact parts, and install with clean lines and watertight details. Start your project consultation today.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com