Custom Fabrication

Frame fabrication is the craft of transforming raw steel or aluminum into a rigid, load bearing structure. It starts with intent. Engineers define loads, connection points, clearance, and service requirements. Those decisions guide material choice, joint design, and the layout of tubes, channels, or plates. The best frames are not the heaviest. They are the most efficient, where geometry and carefully placed gussets handle real world forces without adding unnecessary mass.

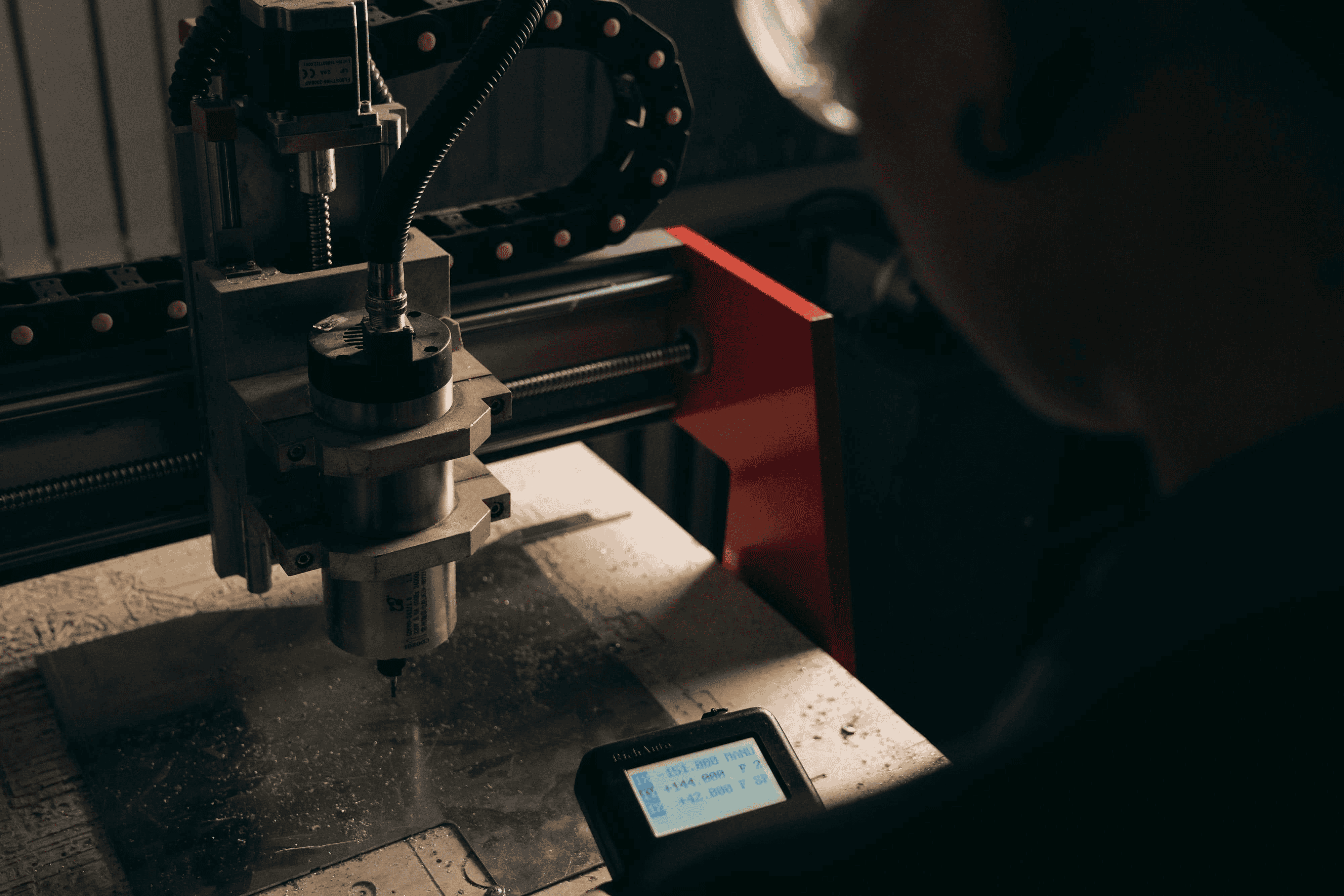

Frame fabrication on a welding table in Fayetteville Arkansas

A dependable frame is the outcome of consistent steps, each verified before the next begins.

Frame fabrication lives or dies by fixturing. Precision jigs lock parts at the correct angles and dimensions so welds do not pull assemblies out of square. Reference surfaces, stop pins, and clamp points help a metal fabrication company repeat accuracy across multiple builds. Design for manufacturing calls for clear datum schemes and tolerances that are tight enough for function yet realistic to produce.

Sawing, laser cutting, and plasma cutting shape parts. For sheet metal fabrication, press brakes create brackets, tabs, and skins that tie tubes and rails together. Clean edges and consistent bend radii simplify fit up and reduce rework. When parts nest properly, welders spend less time fixing gaps and more time making quality welds.

MIG excels for speed on mild steel. TIG provides greater control for thin wall, aluminum, and aesthetic joints. Preheat, interpass temperature, and weld sequencing limit distortion. Tack welds hold geometry before final passes. Where heat could pull parts, welders alternate sides and balance their beads to keep the frame true.

Quality control verifies that the frame meets design intent. Builders check diagonals, measure critical hole locations, and confirm flatness. Visual inspection finds porosity, undercut, or lack of fusion. When higher assurance is needed, dye penetrant and magnetic particle testing reveal surface flaws, and load tests confirm stiffness and ultimate strength.

Sheet components often complete a frame’s story. Skins, cross members, and bracketry convert a collection of rails into a single, efficient structure.

Strategic use of ribbed panels, hat channels, and formed angles can deliver the same stiffness as heavier solid sections. This is how metal frame fabrication achieves better strength to weight ratios while keeping material costs in check.

Battery trays, cable runs, access doors, and mounting flanges are easiest to build with sheet forms. These parts provide clean interfaces for hardware and protect sensitive components. Good design also leaves room for tools, allowing future maintenance without disassembly.

Bare steel will rust. Powder coat, e coat, galvanizing, and ceramic coatings extend life in wet and salty environments. Aluminum benefits from anodizing or powder. Prep matters as much as the finish itself. Clean, profiled surfaces help coatings lock in and survive vibration and heat cycles.

Capabilities determine outcomes. Look for a shop that works from clear drawings or can produce them, holds tolerances with dedicated fixtures, and documents material traceability when required. Ask about welder qualifications and process controls. Reliable partners will discuss distortion control, inspection plans, and timelines without vague promises. The best results come from honest collaboration and early design feedback, especially when frame fabrication must balance cost, performance, and speed.

For deeper detail on brackets, mounts, and precision add ons, explore our custom fabrication. You can also review our focused fabrication services and see how we approach quality on Why Choose OZK Customs.

At OZK Customs in Fayetteville Arkansas, we design and build frames the same way we build adventure platforms, with a practical eye for how they will live outside the shop. Whether you need sheet metal fabrication for brackets and skins or full metal frame fabrication for a chassis or substructure, our team delivers square, straight, and clean assemblies. Bring your drawings or your goals, and we will refine the plan, fixture it right, and weld it to last.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a concept into a road tested structure? Our team designs, fixtures, and welds frames with the same care we put into adventure rigs. Tell us how you plan to use it, and we will build the right solution with clean welds, tight tolerances, and a finish that lasts. Share your project details to get a tailored quote.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com