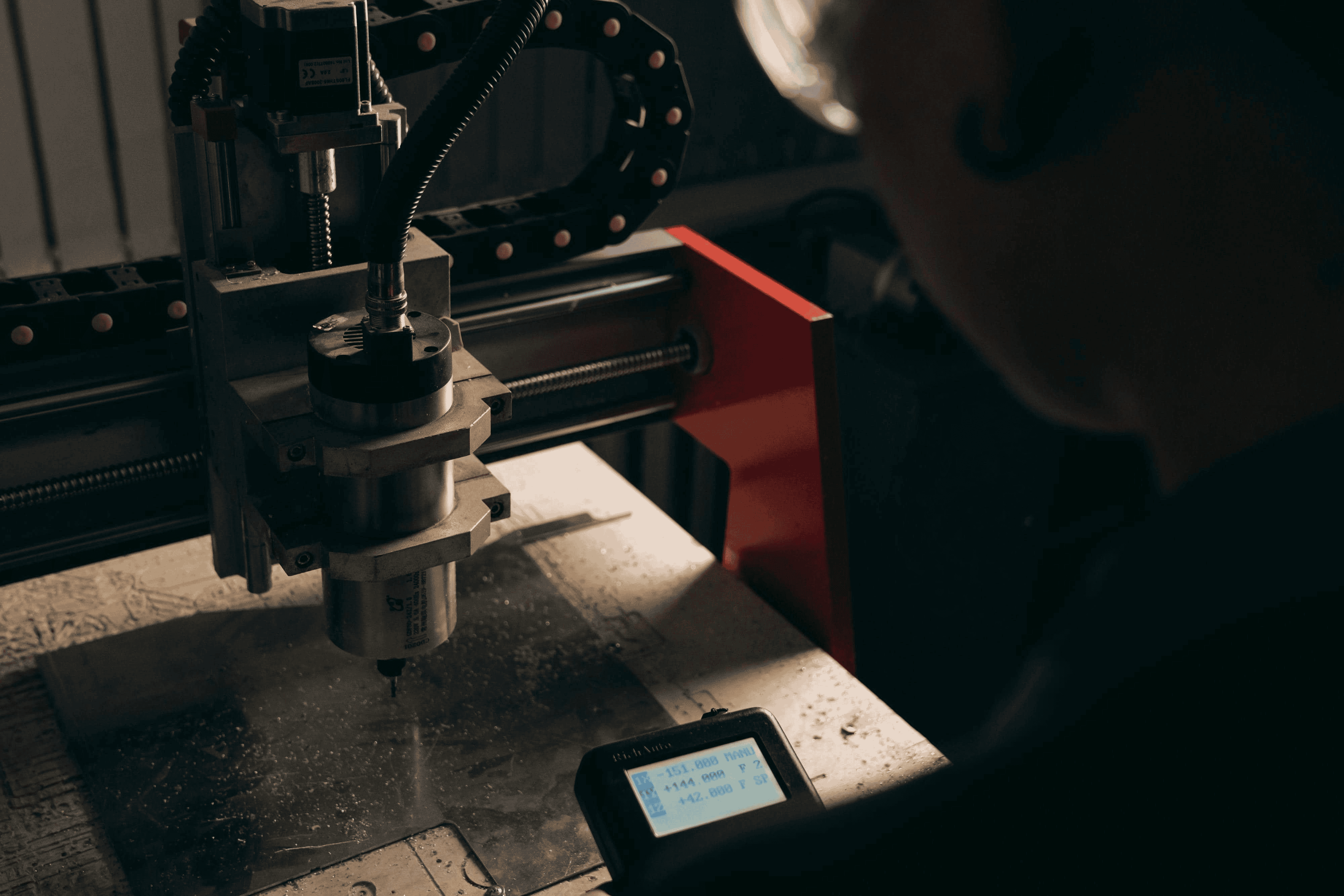

Custom Fabrication

Welding certification confirms that a welder can deposit sound metal under a defined set of variables and a governing code. A qualification is always tied to a procedure, base material, filler, position, and process. Most shops rely on standards such as AWS D1.1 for structural steel, AWS D1.2 for aluminum, ASME Section IX for pressure work, and API 1104 for pipelines. The result is a welder performance qualification record that lists exactly what was qualified, from joint design to positions and thickness ranges. Because quality depends on skilled execution, the certification is earned by doing, not by theory alone.

A typical qualification begins with a written procedure that outlines current, travel speed range, preheat, interpass control, and other variables. The welder follows that document to make a test coupon. After visual inspection, the coupon is cut into strips, planed, and bent to reveal any hidden flaws such as lack of fusion or inclusions. Some codes allow radiographic or ultrasonic testing in place of bends. In every case, pass or fail is decided by measurable criteria set by the code, not by opinion.

Welder performing bend test for welding certification at OZK Customs in Fayetteville Arkansas

Structural fabricators often test to AWS D1.1 in flat, horizontal, vertical, or overhead positions, using processes like GMAW, FCAW, GTAW, or SMAW. Aluminum work may require AWS D1.2, which places emphasis on heat input control to protect the heat affected zone. Piping and pressure parts typically follow ASME Section IX, with coupons prepared as pipe or plate and evaluated by bends or radiography. Each code defines what a pass covers, and what requires retest.

Expect fit up and joint cleaning first. The root pass sets the tone, followed by fill and cap while monitoring interpass temperature and bead profile. Inspectors watch for porosity, undercut, excessive reinforcement, and arc strikes. Coupons are labeled to maintain traceability before cutting and bending. Documentation is completed only after acceptance.

Most certifications require continuity, meaning the welder must perform the qualified process within a defined interval to keep it current. Shops maintain continuity logs and may requalify after lapses. Adding a new material, thickness range, or position commonly requires another test. Think of it as a living credential that tracks your proven capability.

True no cost testing is uncommon, but cost relief exists. Community colleges and technical centers sometimes bundle the test into tuition and use grants to reduce your bill. State workforce programs funded under the Workforce Innovation and Opportunity Act may sponsor training and testing for in demand trades. Apprenticeships through unions or certain employers can place you on a payroll while preparing you for the test, effectively making your certification cost neutral.

If you search free welding certification or free welding schools near me, focus on these routes:

A free online welding certification test does not exist in the official sense because a human must witness your weld and a lab must evaluate it. Still, online practice tests can build your code knowledge, symbols, safety, and math. Use them to prep, then schedule a hands on qualification through an accredited test facility or a school partner. When you budget, account for test plates or pipe, lab fees, and any required retest, since those items often sit outside tuition.

Stack credentials with intent. Start with the material and process you will use the most, then add positions or processes that broaden your range. Pair your certification with blueprint reading, fit up, and measuring skills so you can deliver assemblies that install without rework. Keep a tidy continuity record and a portfolio of macro photos that clearly show your bead control on different joints. Above all, treat safety and weld prep as nonnegotiable habits. Great welders are consistent welders.

Certification also matters to the shop that hires you. It reduces onboarding risk, speeds assignments to critical work, and supports traceability for customers who specify code level requirements. When you present your welder performance qualification record, be ready to explain the ranges it covers, such as qualified thickness, position limits, and similar base metals under the code.

When your projects require professional fabrication with documented quality, our team can help. At OZK Customs, we build structures and components that must hold up to real world use, so our process control, fit up discipline, and inspection standards match the job. If your design calls for brackets, racks, bumpers, or aluminum assemblies, our shop can produce them with the right process and documentation. Explore our custom fabrication, see how we approach fabrication services, and learn more about why choose OZK Customs before you submit your scope.

Bring us your concept and functional requirements. We will review your drawings, identify the right materials and weld processes, and outline a production plan that meets your performance target. Whether you need structural steel, formed aluminum, or precise stainless work, we build for the trail, jobsite, and highway. Fill out the form and we will respond with a clear next step toward a finished part or assembly.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to put certified welds to work on your build? Tell us about your project and our team will propose a path from concept to finished metal with code level quality where your application demands it. Submit the form to start with a design review and a clear, written scope.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com