Custom Fabrication

Architectural metal cladding turns walls into hard wearing, design driven surfaces that resist dents, clean easily, and withstand tough environments. Beyond looks, it adds fire resistance when paired with the right substrates and can protect exterior assemblies from weather. Custom metal panels allow precise sizing, perforations for airflow or acoustics, and edge treatments that make corners and seams read as deliberate lines. On interiors, metal walls create contrast against wood, stone, or plaster and bring light play through texture and sheen. On exteriors, corrugated profiles shed water, while flat or cassette systems give a modern, planar look.

Interior tin wall panels are a classic choice for warmth and shimmer, especially in hospitality, retail, and residential feature walls. They fall under the broader family of interior metal wall panels, which also includes steel, aluminum, and zinc in smooth, beaded, or embossed patterns. Decorative tin wall panels lend vintage character, while decorative metal wall panels interior projects often favor powder coated aluminum for crisp color and low weight. Designers also use sheet metal interior walls with reveal joints to create monolithic surfaces that still breathe through discreet seams. For a rustic approach, a tin sheet wall or galvanized wall panels bring muted silver tones and a protective zinc layer that resists corrosion.

When planning metal interior walls, consider fire rating, substrate, and acoustic performance. Most panels achieve excellent fire behavior when installed over non combustible backers, and perforated custom metal panels with acoustic batts can reduce echo in lively rooms. For high touch spaces, dent resistant gauges and reinforcing at traffic zones keep surfaces tidy over time. Thermal comfort also factors into feel, so use proper insulation and separation from exterior assemblies where temperature swings are significant.

Finish governs both appearance and maintenance. Galvanized metal wall panels and galvanized steel panels for walls offer a protective zinc layer with a matte silver look that weathers gracefully. Clear coats lock in the current tone, while powder coat expands the palette from soft neutrals to bold accents. Brushed, bead blasted, and embossed textures change how light breaks across the plane, and decorative metal wall panels can combine textures with color for depth. If a natural patina is desired, specify it intentionally and plan for run in areas to age uniformly.

Successful installs begin with flat, plumb substrates and planned joints. Hidden fastener systems deliver clean faces, while exposed fasteners can support industrial aesthetics. For wet zones, integrate flashings, back pans, and sealants with compatible chemistry to protect edges. Where dissimilar metals meet, use separation to prevent galvanic reactions. On existing drywall, furring creates a true plane and a ventilation path where needed, and careful layout places seams away from eye level for a refined read.

Corrugated metal panels for exterior walls move water quickly and are cost effective for large spans. Flat lock, standing seam, and cassette systems deliver a smooth, contemporary façade with tight shadow lines. The transition from exterior to interior surfaces is a design opportunity. Carrying the finish inside, or echoing it with interior metal wall panels, unifies the story of the building. Thoughtful terminations at floors and ceilings, including shadow reveals or scribed edges, keep metal wall covering details sharp and maintainable over time. When seeking metal wall covering ideas, think of light direction, adjacent materials, and touch points to guide the choice of profile and finish.

Metal wall covering can be minimal or expressive. Decorative metal wall panels can act like art, while galvanized wall panels deliver honest function in service areas. In kitchens and labs, sheet metal interior walls are easy to sanitize. In entry areas, decorative tin wall panels add a welcoming glow. The key is to align profile, gauge, and finish with the task of the room.

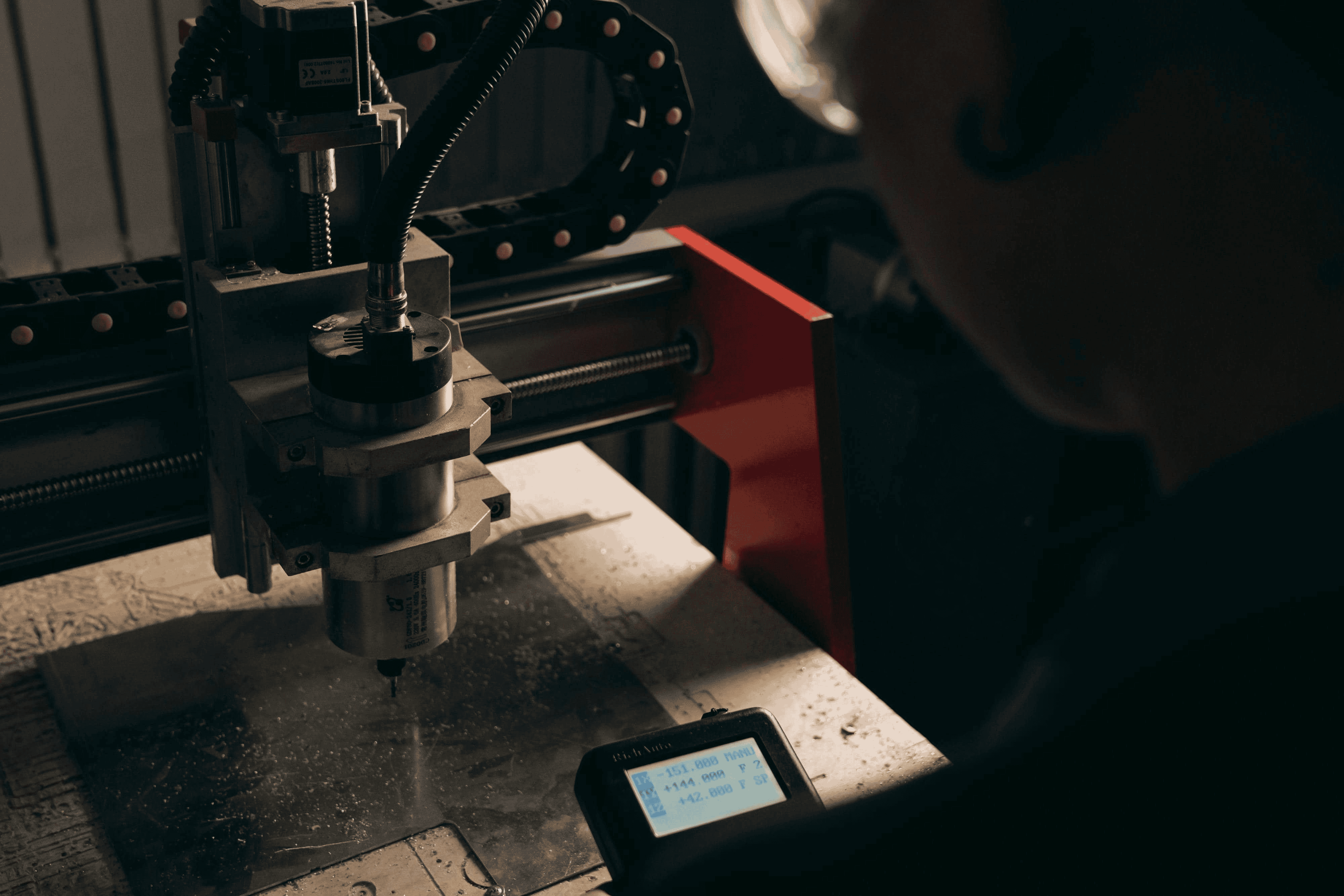

Design intent becomes real through precise fabrication. Complex corners, radius panels, and integrated vents benefit from a partner that can form, notch, perforate, and finish to tight tolerances. If your project calls for custom sizing, stiffening beads, or hidden attachment points, experienced metalworkers can fold those needs into the drawings and shop work. Explore Custom fabrication to see how tailored parts keep installs clean and predictable, even when walls are not perfect.

For scope clarity and process steps, review our Fabrication services which outline material options, finishing paths, and quality checks suited to architectural metal cladding. If you want to understand how teams, tools, and standards translate into a smooth build, visit Why OZK Customs.

Whether you are after interior tin wall panels for a heritage vibe, decorative metal wall panels for a gallery like effect, or galvanized steel panels for walls in high traffic zones, the path is the same. Start with the environment, pick a profile that supports cleaning and wear, and specify a finish that looks right in your light. For exterior continuity, consider corrugated metal panels for exterior walls that complement interior selections. For interior feature zones, curate a short list of metal wall covering ideas that balance color, texture, and reflectivity.

If you are ready to translate concept into precise parts, OZK Customs can engineer and build custom metal panels sized to your layout, complete with mounting strategies, reveals, and finish documentation to streamline installation. Share your drawings, room conditions, and target finish, and we will turn them into a fabrication ready package backed by craftspeople who understand design intent.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to spec custom metal panels for your space? Share dimensions, environment, and finish goals. OZK Customs will propose materials, profiles, and timelines tailored to your project.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com