Custom Fabrication

Metal machining services convert raw metal into purpose built parts by removing material with controlled cutting motion. At the heart of this work are CNC milling centers that sculpt complex contours and flat features, and CNC lathes that produce round geometry like shafts, spacers, and adapters. Drilling and tapping create threaded holes, while grinding refines flatness and surface finish beyond what cutting tools alone can achieve. For features that are hard to reach or require extreme accuracy, shops may add EDM, which uses electrical discharge to erode tiny amounts of material.

A reliable machine workshop plans each job with workholding, tool selection, and toolpaths that keep parts stable while cutting forces act on them. Tool wear and heat generation are managed with coolant flow, speeds, and feeds tuned to the material. Precision depends on more than the machine itself. Fixturing, gauging, and in process checks keep dimensions within tolerance from the first part to the last.

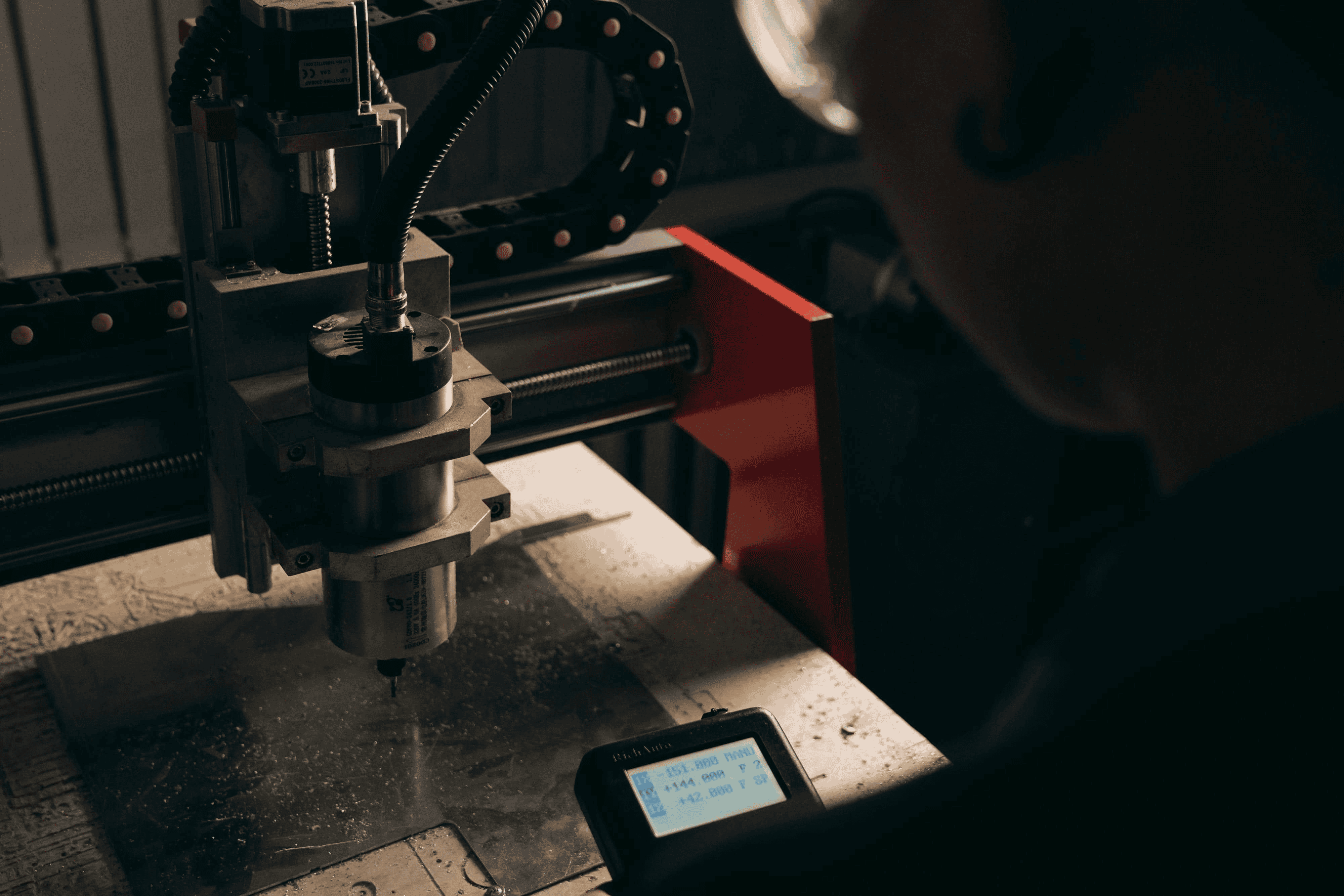

Metal machining services inside a machine workshop turning and milling precision parts for custom vehicle builds and assemblies.

A modern machine workshop runs like a small factory with high resolution control. Engineers translate models and drawings into CAM programs, simulate tool movement, and set up fixtures that allow multiple faces to be cut in one cycle. Repeatable zero points and probing eliminate guesswork during set up. After cutting, deburring, bead blasting, or tumbling may be used to remove sharp edges and normalize appearance. If the part needs more strength or corrosion resistance, heat treatment and anodizing or plating follow.

Quality control starts with the drawing. Clear tolerances, GD and T, and surface finish callouts tell the shop what to measure and why. Coordinated measuring machines, height gauges, and surface roughness testers verify critical features. For production runs, a control plan and first article inspection lock in the process before volume ramps.

Tight tolerances reduce play, improve alignment, and increase the life of assemblies, but they also add cost and lead time. Savvy buyers specify tight control only where function demands it, and allow looser non critical areas to speed production. Surface finish influences friction, sealing, and fatigue life. Machined finishes are often enough for structural brackets, while sealing faces or bearing bores may require grinding or polishing.

Aluminum alloys like 6061 and 7075 machine quickly and offer excellent strength to weight. Stainless grades such as 304 and 316 resist corrosion for outdoor and marine exposure. Tool steel brings hardness for wear surfaces, while titanium pairs low weight with exceptional strength for high stress parts. Matching material to the environment saves weight, cost, and failure risk.

Machine shop manufacturing can deliver a single prototype in days, then scale to batches with controlled cost per part. Palletized workholding, standardized cutters, and program optimization keep cycle times consistent. For ongoing production, shops stage raw material, kitted hardware, and inspection fixtures so that every lot follows the same playbook.

Picking a machining partner is about more than hourly rates. Look for demonstrated accuracy on similar parts, a thoughtful approach to workholding, and clear communication on design for manufacturability. Shops that ask good questions about loads, environment, and mating parts tend to catch risks early. Ask how they handle traceability, material certs, and special processes like heat treat or plating. Review sample inspection reports to confirm that measurement capability matches your tolerances.

Lead time depends on shop loading, complexity, material availability, and any secondary finishing. If the part must align with welded structures or composites, involve the machinist during design so datum choices simplify set up and inspection. When drawings include clear datums, callouts, and notes on critical features, the machinist can deliver accuracy without guesswork. This is how consistent quality emerges across lots and revisions.

When those machined parts need to live inside a vehicle or trailer, integration becomes as important as precision. Brackets, mounts, and housings should be designed around real world loads, splash zones, and service access. This is where machining intersects with fabrication, wiring, and installation, and where a team that understands the entire build delivers stronger results.

For complex assemblies that bridge machining and fabrication, see our Custom fabrication overview. If you want a deeper look at our capabilities across CNC, plasma, and metal finishing, explore our Fabrication services. Curious about process, craftsmanship, and how we support owners from design through handoff, read Why choose OZK.

OZK Customs pairs metal machining services with fabrication and installation so your parts do more than measure well, they live well. We translate load cases into smart geometry, choose materials suited to weather and vibration, and validate fit inside the full vehicle system. Whether you need a run of aluminum brackets, a stainless adapter for underbody systems, or a milled housing that ties into a welded structure, our Fayetteville shop treats your part like it will carry you across a state line.

Tell us what the part must do, where it lives, and how it will be serviced. We will help refine the drawing, plan the process, and deliver a component that installs cleanly and performs under pressure.

We're happy to talk specs, fitment, or just bounce ideas around.

Have a part that needs to be machined for your van or overland build? Share your goals and constraints, and our Fayetteville shop will map a fast, precise path from concept to installed component.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com