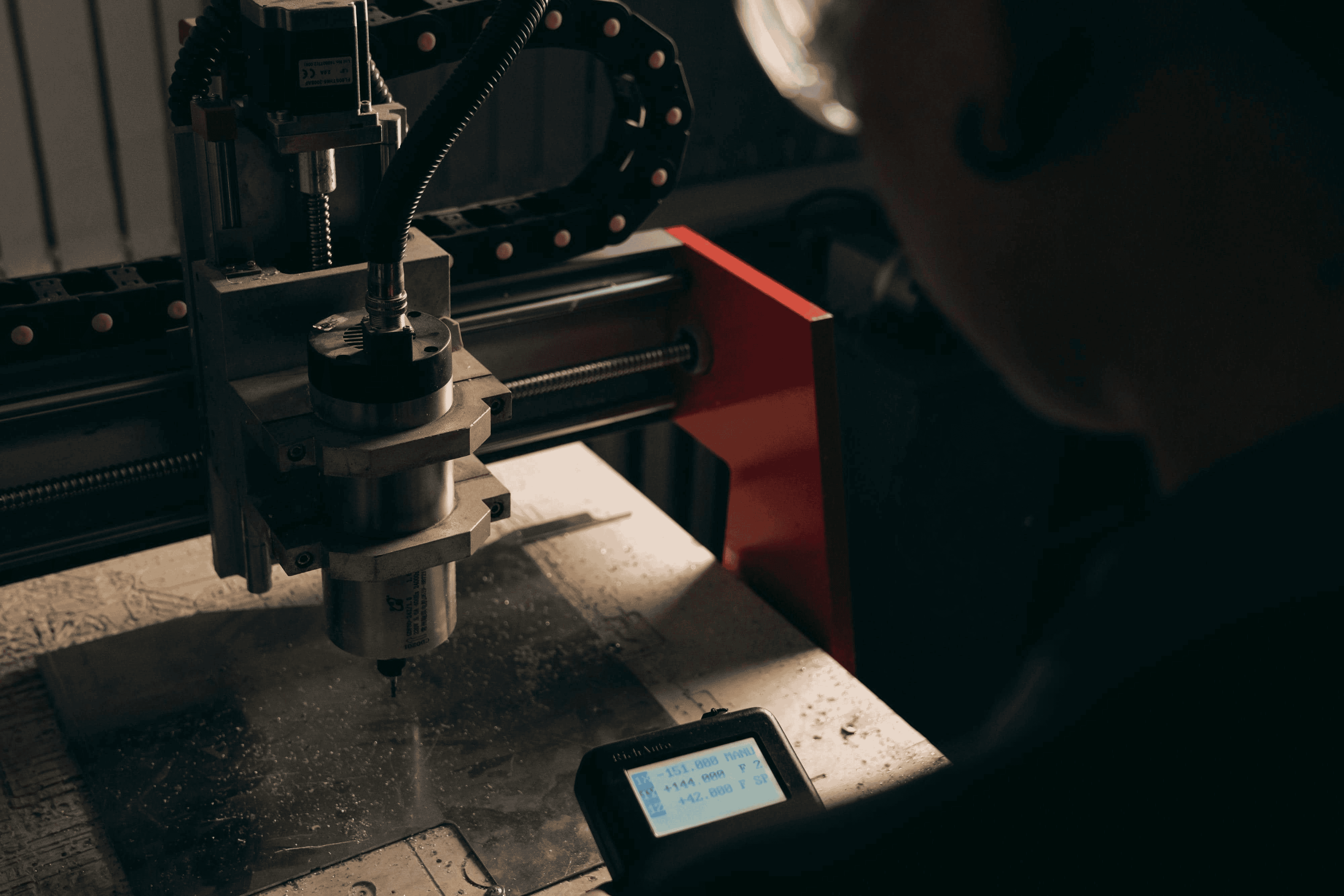

Custom Fabrication

Metal finishing transforms raw stock into parts that resist corrosion, wear, and contamination while looking clean and consistent. Surface prep often starts with degreasing, alkaline wash, and media blasting to create an even profile for coatings to bite. From there, finishing may be mechanical, chemical, or organic coating. Mechanical options include grinding, sanding, bead blasting, vibratory tumbling, and high polish for a mirror sheen. Chemical and electrochemical methods include anodizing for aluminum, passivation for stainless, phosphate conversion for paint adhesion, and various plating systems such as zinc, nickel, or chrome. Organic coatings range from solvent paint and electrodeposition coating to modern powder coating systems that deliver thick, uniform films and strong edge coverage.

Metal finishing services for automotive and fabrication projects in Fayetteville Arkansas with powder coating, anodizing, and inspection for long lasting performance.

The right choice depends on the metal, work environment, and design details. Aluminum housings benefit from anodizing with sealed pores for improved hardness and color stability. Stainless assemblies often get passivated to remove free iron and sharpen corrosion resistance without changing dimensions. Steel brackets destined for road use may receive zinc plating with a conversion sealer or a phosphate base followed by powder coating for layered defense. For high heat areas, ceramic style coatings and high temperature powders help color and gloss survive exhaust proximity.

Comparing providers starts with capability and ends with proof. Verify part size limits, racking methods, and masking skill for threads, bores, and mating faces. Ask about media types for blasting, grit sizes, and whether they can radius edges to help coating wrap. Review documentation practices for thickness readings, color standards like RAL cards, and lot traceability. Environmental stewardship matters too; look for modern chemistries, compliant wastewater treatment, and clear safety data.

When your search includes the phrase metal finishing companies near me, think beyond proximity. Evaluate turnaround under real timelines, consistency across batches, and how the shop handles complex assemblies. A supplier that can advise on design for finishing often saves rework by adding drain holes, adding hang points, or adjusting edge breaks before coating.

Reliable finishing is measurable, not just visible. Common checks include coating thickness via magnetic or eddy current gauges, hardness and microstructure for anodic films, gloss and color readings, and adhesion using cross hatch tests. Corrosion testing may include neutral salt spray per widely accepted methods, and humidity exposure for coating integrity. Dimensional checks confirm that critical bores and slides remain in spec after finishing.

Vehicles and field gear live tough lives. Brackets see road salt, gravel, and pressure wash cycles. Roof racks and sliders take repeated contact and UV. That means pretreatment is as important as the topcoat. Clean metal, proper profile, chemical conversion, and controlled cure cycles are the foundation. Masking keeps threads and bearing surfaces clean. Fixturing and racking ensure even film build and prevent sags or thin edges. For aluminum, sealed anodize layers help fend off staining and provide a consistent base for dye colors.

Automotive and outdoor hardware also benefit from maintenance minded choices. Dark textures hide scuffs. Satin finishes reduce glare on dashboards and panels. For serviceability, consistent color codes and documented batches simplify future touch ups or part swaps. If your parts will live in Fayetteville Arkansas and across Northwest Arkansas trails, plan for humidity, red clay, and winter brine. You want finishes that shrug off wash bays and gravel without flaking.

OZK Customs builds and finishes parts for real road use, which means we think about finishing from the first cut. Our team handles design for finishing, proper edge prep, and clean fixturing so your coating or anodize performs. See how our shop approaches end to end builds and finishing on our custom fabrication page. If you are scoping a specific process list, browse our fabrication services to map your parts from raw metal to finished assembly. Want to understand how we work and why customers trust us with mission ready rigs and components? Visit why choose OZK Customs.

If you need powder coated brackets, anodized aluminum panels, plated fasteners, or a complete assembly that is finished and ready to install, we can help. Located in Fayetteville Arkansas, we support Northwest Arkansas and nationwide clients with fabrication, finishing management, and documented quality checks. Tell us where the part will live, how it will be used, and the look you want. We will recommend a finish stack, prepare your parts correctly, and deliver components that fit, function, and look the part.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready for a finish that survives real miles and real weather? Tell us about your parts, timelines, and performance needs. OZK Customs builds and finishes parts for adventure vans, overland rigs, commercial vans, and custom fabrications with documented quality. Start your project today and we will spec the right process, manage the finish, and deliver parts that fit and last.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com