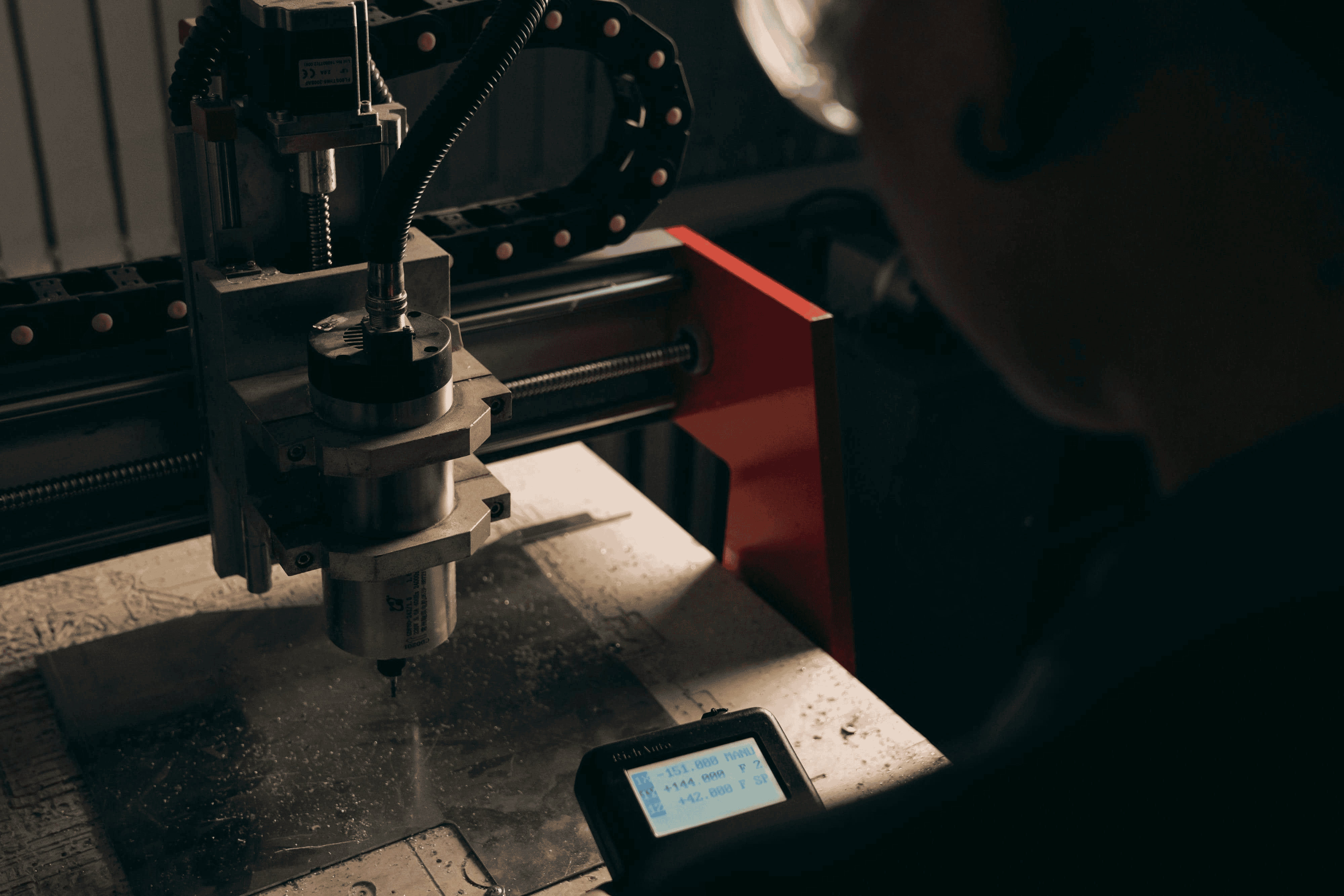

Custom Fabrication

Modern sheet metal fabrication turns digital designs into real metal pieces with speed and accuracy. Metal laser cutting services use fiber or CO2 lasers to slice sheet and plate with a narrow kerf, minimal heat affected zone, and clean edges that often need little deburring. Shops nest parts efficiently to reduce scrap and price your metal order by material, thickness, cut time, and setup. Typical files include DXF, DWG, and STEP, and tolerances down to a few thousandths are achievable on thin gauges with the right process control. Finishes like powder coat, zinc plating, and anodize are often bundled into the quote.

Precision sheet metal fabrication and metal laser cutting services for custom metal parts manufacturing in Fayetteville Arkansas by OZK Customs.

Material choice drives performance. Mild steel cuts fast and costs less. Stainless resists corrosion and shines in food grade or outdoor settings. Aluminum keeps weight down in mobility and vehicle builds. A skilled metal steel company will also advise on flatness, grain direction, and temper that affect forming and cosmetic results. When small metal pieces require tight hole to edge spacing or fine slots, beam quality and assist gas selection make the difference between a clean part and a warped one.

On thin gauges, nitrogen cutting yields bright, oxide free edges ready for welding or finishing. Oxygen can increase speed on thicker plate but leaves scale that may need prep. Good practice includes tabbing for part stability, micro joints where required, and clear etch marks for bend lines. Ask about inspection: first article checks, dimensional reports, and traceability to keep custom metal parts manufacturing consistent.

After cutting, metal bending services shape parts with press brakes using air bending, bottoming, or coining. The bend radius, K factor, and tooling choice determine repeatability and flat layout. Designers should consider minimum flange lengths, relief cuts near corners, and hole distortion along bend lines. Precision forming is vital when small metal parts manufacturing demands stacks of brackets or boxes that must assemble without brute force.

Thin aluminum may crack if the radius is too tight, while stainless springs back more and needs compensation. For cosmetic surfaces, protective film helps avoid die marks. Rivnuts, PEM fasteners, and spot welds bring small assemblies together without bulky hardware. When features are tighter than a press brake can handle, shops may switch to hemming, bump bending, or even machine a form to hit demanding geometry on delicate small metal pieces.

Provide a flat pattern with bend notes, inside radii, and a clear gauge callout. If you do not have a flat, supply a model with accurate wall thickness and let the fabricator generate it. Include tolerances for critical dims only to keep the quote realistic and ensure manufacturability. Finishing adds thickness, so plan clearance where powder or plating goes.

When searching metal fabricators near me or a metal shop near me, evaluate capability, communication, and consistency. A responsive team will confirm materials in stock, realistic lead times, and options if your spec is unusual. Look for fiber laser capacity, tonnage and width on press brakes, welding certifications, and a clean quality workflow. If you rely on a sheet metal store near me or sheet metal places near me for raw material, confirm whether the fabricator can source directly so you avoid delays. Strong relationships with metal parts suppliers keep your job moving during market swings.

Local support is valuable, yet remote vendors can excel if they provide fast quoting and clear packaging. Fayetteville Arkansas sits in a central corridor with easy ground shipping, which shortens transit times for many states. When you place a metal order, include quantity breaks so the shop can optimize nests and give you tiered pricing. Share your end use so the team can recommend finishes and assembly best practices. For prototypes, ask for a photo review before shipping to catch adjustments early. If you prefer to visit a metal company near me, walk the floor and look for organized staging, labeled material, and documented inspection points.

As you narrow options, weigh total value over unit price. Reliable communication, repeatable quality, and accountable scheduling often beat the lowest quote in the long run.

For complex assemblies and vehicle grade components, it helps to partner with a shop that understands fit, finish, and field use. In addition to standard sheet metal fabrication, a team that builds real world products can flag hidden risks like thermal expansion near electronics, galvanic corrosion between metals, and mounting stress on thin walls. That insight shortens your path from drawing to durable parts.

You can explore custom fabrication to see how an integrated approach handles cutting, forming, welding, and finishing under one roof. If you are comparing capabilities, review our fabrication services to understand process options and materials we run every day. Curious about partnerships, quality, and customer experience, read why choose OZK for a look at our standards and approach.

In short, a dependable partner makes ordering metal pieces straightforward. Share clean files, call out what truly matters, and choose a fabricator that treats your parts like their own. Whether you need one prototype or a repeat run, the right process will get your parts packed, protected, and delivered on time from Fayetteville Arkansas to your dock.

If your project needs metal laser cutting services, metal bending services, and small batch or production scale custom metal parts manufacturing, our team can help. Send your drawings and requirements, and we will turn them into precise parts that fit first time.

We're happy to talk specs, fitment, or just bounce ideas around.

Have CAD files or a napkin sketch ready to go? Send your metal order to OZK Customs and our fabrication team will quote laser cutting, bending, and finishing on one streamlined ticket. We build precise parts, communicate clearly, and ship fast from Fayetteville Arkansas. Submit your project and let’s cut, form, and finish it right.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com