Custom Fabrication

Architectural metal cladding wraps a structure with a durable, lightweight exterior that manages weather and elevates design. From folded aluminum to weathering steel to zinc and copper, these systems balance performance with an expressive finish. Properly detailed assemblies shed rain, ventilate behind the surface, and protect thermal layers from wind and moisture. Paired with the right substrate and barriers, cladding extends service life while keeping maintenance predictable.

Architectural metal cladding facade detail showing a ventilated metal panel system on a high performance exterior

Most architects begin with a drained and ventilated rainscreen. The cladding sits on a subframe, a continuous air and water barrier seals the backup wall, and an air cavity helps pressure equalization. Open joints or baffled joints allow controlled airflow while maintaining water management. In cold or mixed climates, the ventilated cavity reduces moisture risk and helps the wall dry. Careful detailing at corners, parapets, and penetrations is essential.

Flat, ribbed, and cassette profiles each deliver a distinct shadow line. Standing seams read crisp and linear, while shingle patterns echo traditional textures with a modern twist. Coil coated aluminum with PVDF finishes provides color stability and clean lines, while steel strengthens impact resistance. Metals like zinc or copper develop a living patina for depth and contrast. Coordinated trims, reveals, and soffits complete the composition.

Metal resists pests, rot, and UV degradation when finishes are specified correctly. Factory applied coatings defend against corrosion and color fade. Touch points include quality fasteners, compatible sealants, and isolation for dissimilar metals. Maintenance often amounts to periodic cleaning and inspection of joints and flashings. With sound design, the assembly performs for decades with minimal intervention.

A metal panel system is the engineered set of parts that fasten the cladding to the structure and manage the building physics behind it. Typical layers include subgirts or rails, thermal isolators, clips, fasteners, and a continuous air and water barrier on the sheathing. Joint design controls movement and works with weeps to drain the cavity. Attachment should consider substrate type, whether steel studs, concrete, or mass timber, and should be tested to suit local wind and seismic criteria. Field mockups validate performance before full installation.

Insulated steel siding can take two paths. One approach uses field assembled rainscreens with exterior mineral wool to reduce thermal bridging and improve fire resistance. The other uses factory made insulated metal panels with foam cores that deliver high R values and fast installation. Select based on code needs, fire testing, detailing tolerance, and schedule. Either route can complement a metal panel building when the thermal target is ambitious.

Review the wall assembly for compliance with energy, wind, and fire requirements. For multi story projects, confirm the assembly meets relevant fire propagation tests. In coastal or industrial settings, specify coatings and substrates that resist aggressive environments. Document penetrations and transitions to adjacent materials to maintain continuity of barriers and insulation. Performance is only as strong as the weakest detail.

Metals vary in stiffness, so confirm panel gauge against the expected wind pressure and aesthetic flatness. Consider substructure alignment and tolerance control, since small deviations show on smooth surfaces. When acoustics matter, add isolation strategies inside the cavity. For sustainability, favor recyclable metals, durable coatings, and assemblies that can be disassembled at end of life. Quality control during layout and fastening yields crisp lines and fewer callbacks.

Thermal expansion matters, especially on long runs and dark colors. Use clips and slotted fastener holes as the manufacturer recommends, and place joints to minimize stress. Build in clear sequencing for corners and terminations, since these areas collect tolerances from multiple directions.

Treat the air and water barrier as the primary line of defense. Continuous transitions at windows, doors, and parapets protect the structure if wind driven rain gets behind the cladding. Sealants should back up mechanical laps, not replace them. Redundancy keeps the envelope resilient.

PVDF coatings lead for color stability and chalk resistance. Textured and low gloss finishes hide oil canning on large flat areas. For natural metals, plan for patina run off and capture staining at drip edges. Clear documentation on cleaning safeguards warranties and service life.

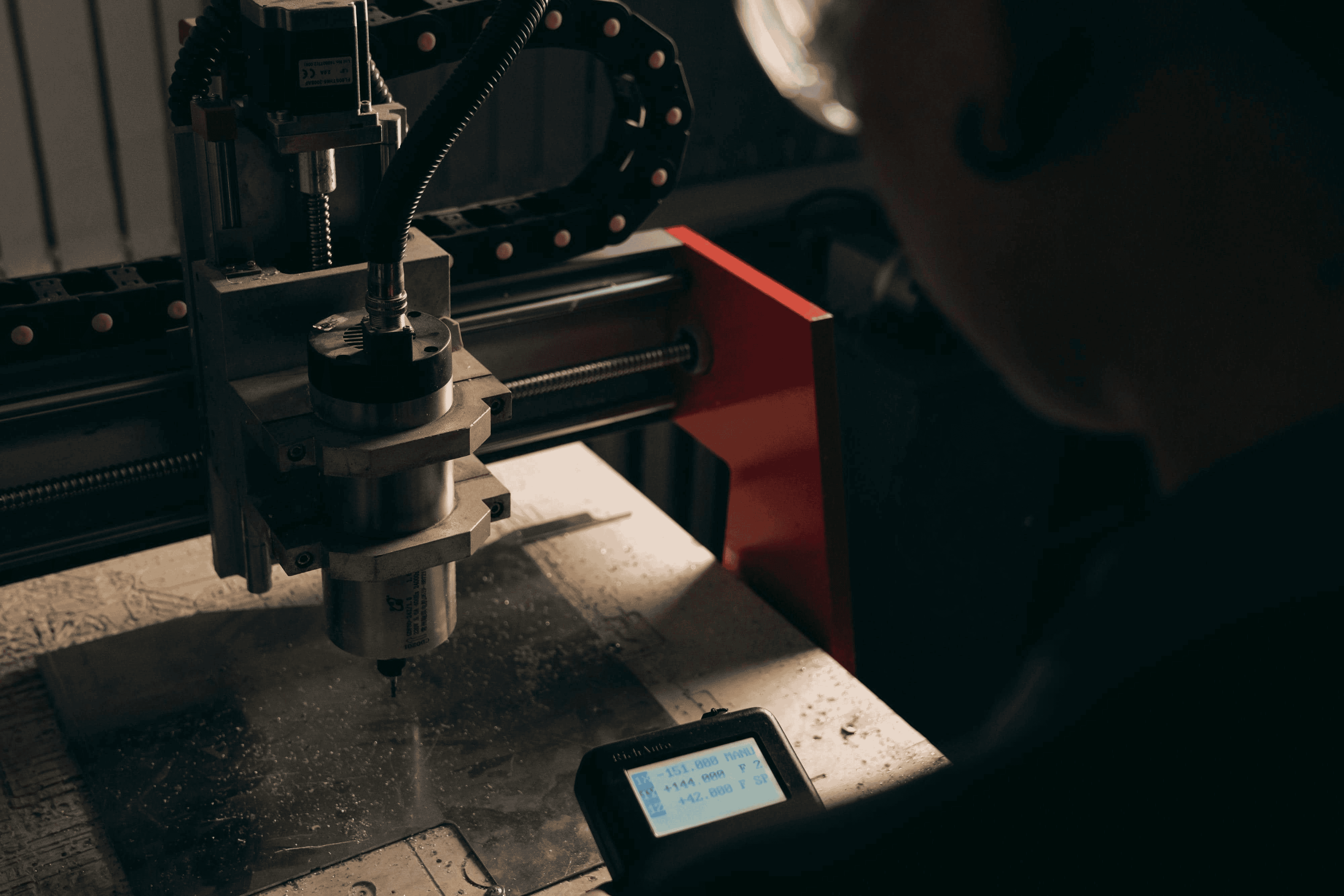

As projects evolve, many teams need custom trims, unique perforation patterns, or specialized brackets to solve field conditions. If you require one off parts or a cohesive set of components, our custom fabrication team can help align aesthetics with performance. We routinely shape metals, route panels, and build precision fixtures that bring complex details to life.

Complex builds benefit from shop aided precision. Our fabrication services include CNC routing, plasma cutting, and custom metal forming that shorten install time and reduce field rework. When schedules are tight, prebuilt assemblies and well marked kits keep crews moving.

You bring the design intent. We translate it into parts that fit, fasten, and perform. If you are exploring architectural metal cladding, a metal panel system, or insulated steel siding, we can design and fabricate the components that make your envelope clean and buildable. See how we work at why choose OZK Customs and then reach out. Tell us about your target look, performance goals, and timeline so we can engineer a package that meets your spec and installs without drama.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a concept sketch into a buildable system? Tell us about your cladding or panel needs. OZK Customs can design, prototype, and fabricate the metal components that make your project stand out. Submit the form and let’s engineer a solution built for your timeline and budget.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com