Custom Fabrication

Custom metal parts manufacturing is the discipline of turning a design into a durable, dimensionally accurate component that performs in real conditions. Shops combine multiple processes to hit target tolerances, surface finishes, weights, and budgets. Typical workflows blend CNC machining, laser or waterjet cutting, precision forming, welding, and heat treatment. Increasingly, additive processes join the mix to unlock internal channels, lattice structures, and weight reduction that conventional methods cannot easily achieve.

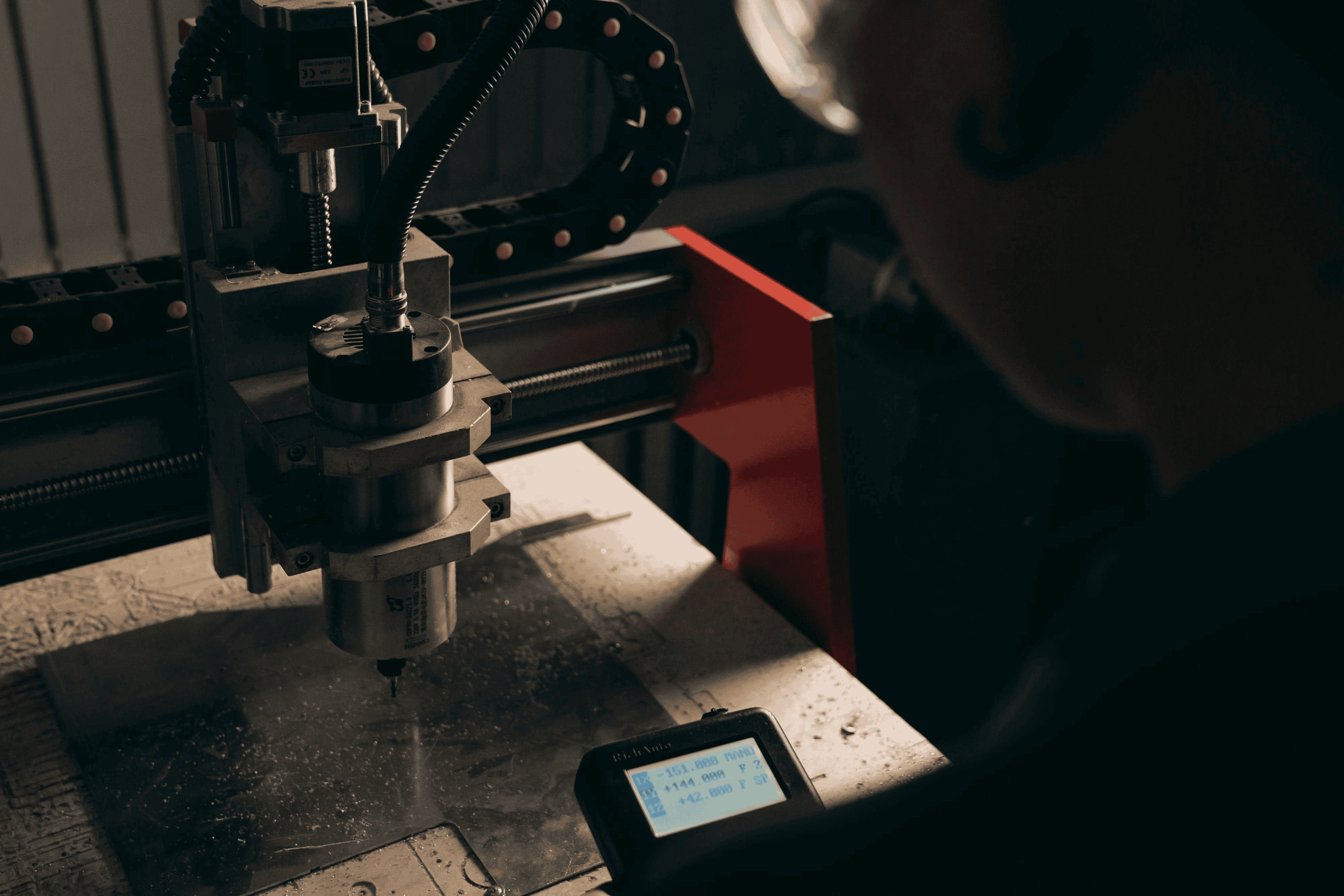

CNC and 3D metal fabrication for custom metal parts manufacturing in Fayetteville Arkansas

At the core, everything starts with a clean model and clear tolerances. For CNC, common materials include aluminum 6061 and 7075 for strength to weight, stainless 304 or 316L for corrosion resistance, tool steels for wear surfaces, and titanium where weight and strength are equally critical. For additive, stainless, tool steel, aluminum, titanium, and superalloys are frequent choices. Post processing steps such as stress relief, machining, and media finishing tune a printed part to spec.

Each method has a sweet spot. CNC leads for tight tolerances and surface quality. Cutting and forming dominate when parts are flat pattern derived. Welding unites complex geometry. Additive shines when designs demand internal features or consolidation of multiple pieces into one.

Material selection drives performance and cost. Aluminum machines quickly and resists corrosion. Stainless handles harsh environments and food or medical contexts. Tool steels provide hardness and wear resistance for fixtures. Titanium offers excellent strength to weight. For metal printing services, material choice also affects laser parameters, build rates, and the need for heat treatment. Designers should balance strength, stiffness, temperature exposure, and finish requirements before locking a spec.

3d metal fabrication is an umbrella term that often includes additive manufacturing for the near net shape, followed by machining to critical dimensions. Compared to full subtractive routes, additive allows organic contours, internal cooling or fluid paths, and topology optimized structures that trim mass without sacrificing strength. Subtractive and forming still outperform in raw surface finish, dimensional stability across large flat features, and per part cost at volume.

Additive processes vary. Laser powder bed fusion delivers high resolution layers and dense parts with fine features. Electron beam approaches can accelerate builds for certain alloys. Binder jetting followed by sintering offers scalability for small to mid sized parts. Each path has trade offs in porosity control, surface texture, and distortion, which post processes correct.

A practical selection framework looks at geometry complexity, annual quantity, required tolerances, target surface finish, and lifecycle loads. Pilot runs validate assumptions before full release.

A successful program moves stepwise from design intent to inspection. Begin with manufacturable geometry and clear GD and T. For additive, add support strategies and plan for removal and finishing. For CNC, optimize tool reach, fixturing, and cutter paths. Confirm critical tolerances and datum schemes. Document material spec, heat treatment, and finish.

Quality assurance protects the result:

Finishing converts a good part into a durable one. Options include anodizing, passivation, powder coat, e coat, zinc plating, and media finishing. Assembly and functional testing close the loop so the part performs under load, heat, vibration, or corrosion as intended.

Once you understand the production landscape, choosing a build partner becomes easier. For vehicle grade brackets, racks, housings, and structural components, precise fabrication and repeatable inspection are essential. OZK integrates these practices in real world builds so parts fit, look right, and last.

For complex or multi process parts, our team coordinates machining, forming, welding, and additive where it creates an advantage. If your design benefits from internal channels or weight reduction, we can evaluate a hybrid path using 3d metal fabrication, then finish machine critical surfaces. Explore our custom fabrication capabilities, and review the range of fabrication services we deliver daily. New to our shop and want to learn how we approach quality and communication end to end? See Why choose OZK Customs.

Bring your drawings, a STEP file, or a napkin sketch. We will help translate your goals into manufacturable features, recommend materials for strength and weight, and guide whether metal printing services, traditional methods, or a hybrid makes the most sense. When precision matters and the part must survive real road miles, we build it to perform.

We're happy to talk specs, fitment, or just bounce ideas around.

Have a drawing, idea, or a problem part that keeps failing? Our team will translate your requirements into a manufacturable plan, quote it clearly, and build it right the first time. Share your project details in the form and let OZK turn your concept into road ready metal.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com