Custom Fabrication

Metal prototyping services bridge design and production by producing physical parts that validate function, assembly, and manufacturability. Teams use prototypes to confirm geometry, check tolerances, and reveal edge cases that CAD alone cannot show. The scope spans sheet metal fabrication, small metal parts manufacturing, and precision metal machining parts for complex features.

Core workflows include material selection, design for manufacturability reviews, and iterative builds. Early choices on alloys, thickness, and bend radii influence strength, weight, and cost. Process capability guides tolerance strategy so features are held where they matter and relaxed where they do not. Measurement plans using calipers, height gages, CMM, or laser scanning help lock down repeatability before production.

Well run programs align prototype intent with the next step. If the goal is quick form and fit, rapid sheet metal is ideal. If the goal is thermal or fatigue testing, machined billets or heat treated stampings may be required. Clear gates keep cycles short and findings actionable.

Common materials include aluminum 5052 and 6061, cold rolled steel, stainless 304 and 316, and copper alloys for conductivity. Typical sheet thickness ranges from thin gauge for electronic enclosures to thicker plate for structural brackets. For bends, inside radius near material thickness reduces cracking and orange peel. Prototypes often target general tolerances around plus or minus five thousandths for machined features and looser for formed features, tightening only where assembly demands it. Finishes such as bead blast, anodize, powder coat, and zinc plating protect parts and stabilize appearance for stakeholder reviews.

Prototype sheet metal parts surface fit and assembly interactions with mate components. Once validated, drawings can add datums and GD and T to guide production consistency. For machined components, fixture strategy and tool selection learned during prototyping carry forward to cycle time and cost improvements. Early supplier involvement reduces surprises when quantities scale.

Sheet metal fabrication for prototypes usually integrates laser cutting or waterjet for profiles, turret or CNC punching for features, and press brake forming for bends. Hardware insertion of PEM fasteners and spot welding or TIG welding enables robust assemblies. Rapid sheet metal prototyping compresses queues by nesting parts efficiently, standardizing bend tooling, and streamlining inspection to only the critical characteristics.

Sheet metal prototyping favors flat patterns optimized for bend allowances and K factor assumptions. Prototype sheet metal parts often use tabs and slots for self locating joints that reduce fixtures and setup time. Where cosmetics matter, grain direction and weld grind plans are defined early to avoid rework. When a design needs additional stiffness, hems, flanges, beads, or ribs can add rigidity without adding much weight.

Pick rapid sheet metal when you need fast iteration on enclosures, brackets, and chassis. It is ideal for verifying clearances, cable routing, airflow, and access for fasteners. It also provides a close read on bend reliefs, hole to bend distances, and panel flatness that drive production feasibility. By the second or third loop, you can freeze geometry with confidence.

Before release, confirm bend order, ensure bendable distance between piercings and edges, and validate hardware callouts. Run a short checklist:

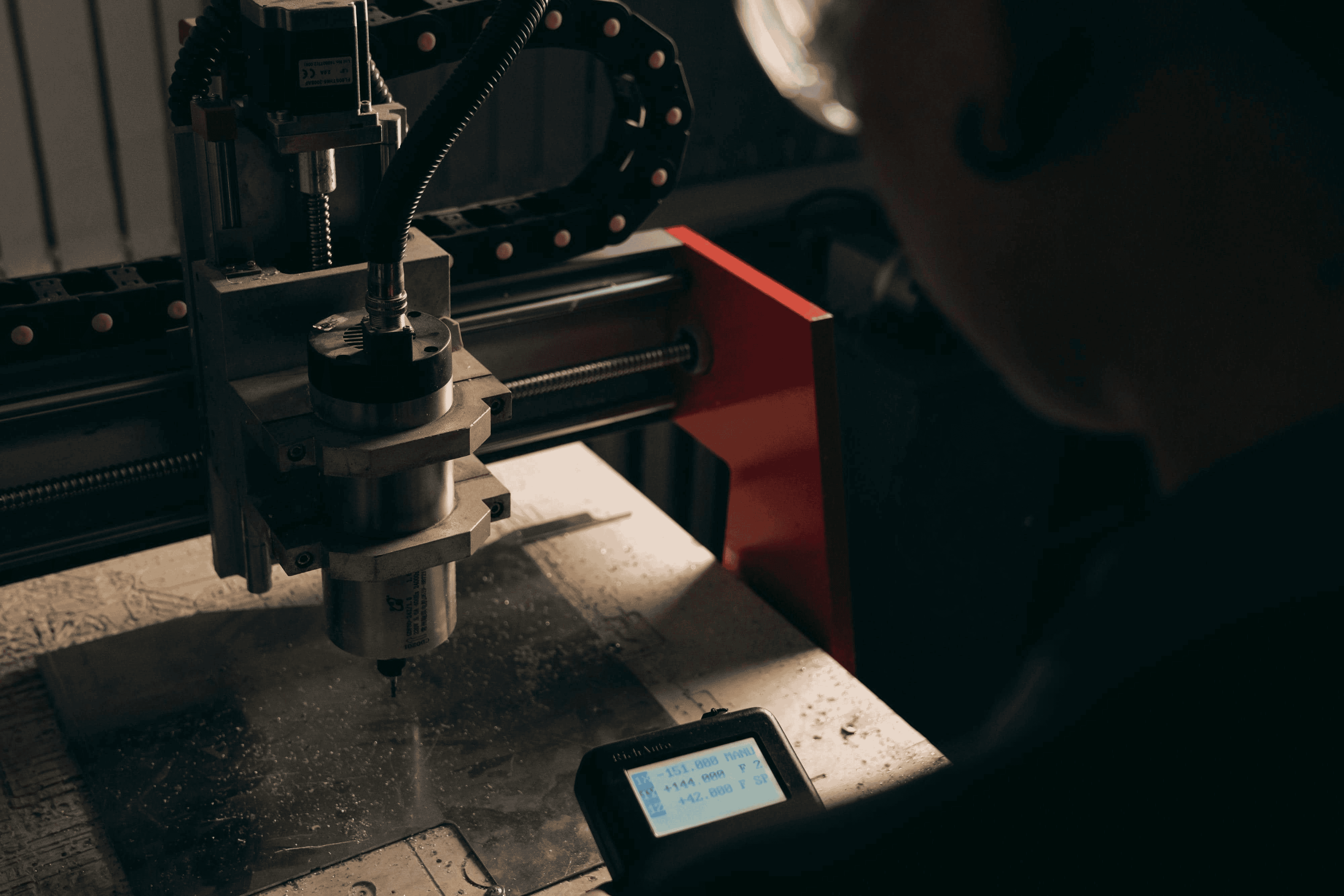

Small metal parts manufacturing often blends CNC milling and turning with secondary ops like reaming, broaching, and thread forming. Metal machining parts excel when tight tolerances, fine threads, or complex pockets are required. For micro features, tool deflection, runout, and coolant strategy can define success as much as the CAM program. Prototype quantities may use soft jaws and modular fixturing to reduce setup time.

For strength critical parts, heat treatment elevates hardness and yield, but it can shift dimensions. Plan for post heat treat grinding or honing if tight tolerances must be held. Surface finish targets should reflect function; Ra values for sliding surfaces can be refined through polishing or superfinishing where necessary.

Choose machining when features require precise bores, flatness, or threads with tight positional control. Choose sheet metal when geometry is dominated by bends, flanges, and large panels. Many designs combine both by welding or fastening machined bosses onto formed shells.

Define datums that match assembly intent. Use go and no go gauges for threads and pins, and CMM for complex true position callouts. Record findings in simple control plans to make the jump to production smooth.

As you evaluate partners for custom metal parts manufacturing, look for clear communication, practical DFM feedback, and repeatable processes. A capable shop should pivot between sheet metal prototype fabrication, small part machining, and finishing without losing speed.

When your design is ready for fabrication, a partner who can cut, form, weld, and machine under one roof trims lead time and reduces back and forth. If you want a deeper look at capabilities, start here: Explore custom fabrication. For a menu of processes from cutting to finishing, see See fabrication services. If you are comparing shops, learn more at Why choose OZK Customs.

We design and build functional metal prototypes that move cleanly into production parts. Whether you need sheet metal prototyping, rapid sheet metal, or precision metal machining parts, our team can translate models into inspected parts with clear documentation. Bring your drawings and requirements, and we will return ready to test hardware that fits, functions, and looks the part.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to move from concept to a tested, production worthy metal prototype? OZK Customs can model, fabricate, and finish your parts under one roof in Fayetteville, Arkansas. Tell us what you need and we will deliver a precise, repeatable part with clear timelines and costs.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com