Custom Fabrication

Metal stamping is a manufacturing method that shapes flat sheet into three dimensional parts with a press and matched dies. If you are asking what is stamping, think of a precise mold that guides the metal as the ram applies force. The stamping process in manufacturing often begins with blanks cut from coil, then moves through piercing holes, forming bends, and drawing deeper shapes. Stamping and pressing produce repeatable geometry with speed, which is why stamping parts appear in vehicles, appliances, connectors, and brackets. When people ask how does stamping work, the short answer is controlled force plus accurate tooling that directs the flow of metal.

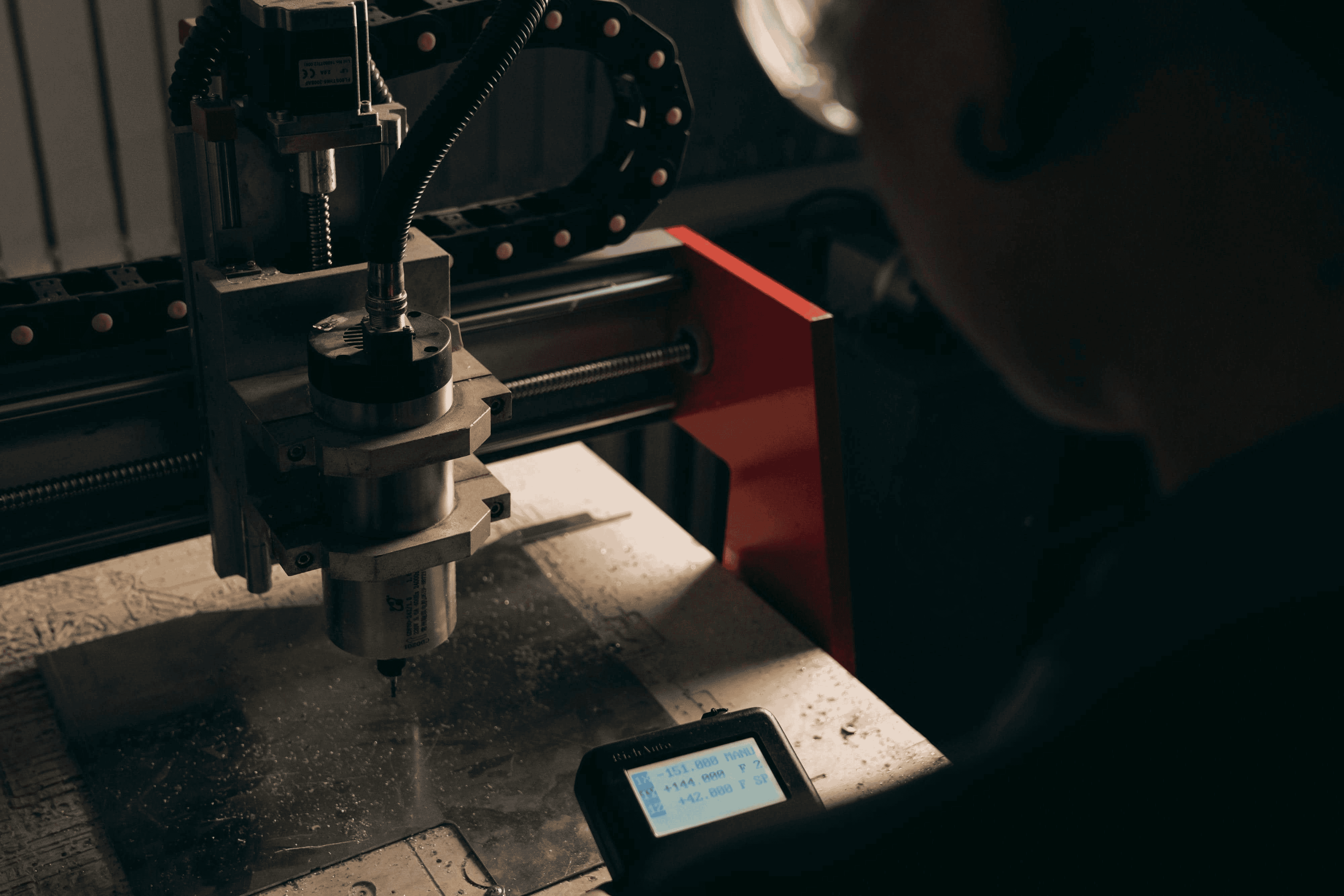

Close view of metal stamping press and tool showing sheet metal stamping process.

The metal pressing process can be done in single hit operations or in progressive dies where the strip advances through multiple stations. Tool stamping metal depends on clearances that match material thickness and strength, lubrication to reduce friction, and press tonnage suited to the cut and form. Stamped steel is common for strength and cost, while aluminum and stainless are used for weight or corrosion needs. Good practice keeps burrs low, springback predictable, and edges free of cracks.

The metal stamping process starts with material selection and part design. Next comes die engineering, where the team defines punch and die geometry, stripper plates, pilots, and carriers. During sheet metal stamping, each station refines the part: blanking defines the outline, piercing creates features, forming adds flanges, and drawing forms deep cups. The sheet metal stamping process balances strain across the part to avoid thinning or wrinkling. Stamping manufacturing reaches high output when feeds, sensors, and coil handling are tuned to the press.

At the heart of metal stamping manufacturing is the die set. Designers model bend radii, draw beads, and reliefs to control metal flow. Tool steels are chosen for wear resistance, while coatings improve galling resistance on stainless or aluminum. Die clearance for cutting is set as a percentage of thickness to manage edge quality and punch life. A robust plan for tool stamping metal always includes maintenance points and easy access for inserts.

Stamped steel sheet remains the workhorse for brackets, body structures, and chassis clips. High strength grades bring lighter designs with equal stiffness, but they demand tighter control of the forming window. Aluminum excels in heat exchangers, trim, and lightweight covers. For each alloy, the stamping process defines punch speed, lubrication, and draw bead depth. Choosing the right stock width and thickness can simplify scrap layout and reduce cost.

Dimensional checks use gauges, vision systems, and coordinate measurement to confirm edges, hole positions, and profiles. Surface inspection looks for galling marks, orange peel, or splits at radii. An easy example of stamping is a battery contact: blank a copper strip, pierce slots, coin the contact area, and form the spring shape in a progressive die. Another example would be a seat bracket in stamped steel with multiple piercings and flanges held within tight tolerances.

Projects often begin with laser cut and brake formed samples to verify geometry before committing to hard tooling. Then the metal stamping manufacturing process advances to soft tools or single stage dies to validate draw and springback. Once stable, a progressive die consolidates steps to raise output. Sensors for strip position, slug detection, and tonnage traces keep the line safe and consistent. This staged approach reduces risk while sharpening cycle time and cost.

Stamping manufacturing thrives on design for manufacturability. Small changes in bend relief, corner radii, and hole to edge distances can improve tool life and reduce scrap. The metal stamping manufacturing process benefits from early collaboration so material, coatings, and press selection support the final spec. When the part demands deep draws, draw beads and blank holder force become the key dials. For high speed connectors, flatness control and burr direction matter most.

Stamped steel sheet parts often slot into welded frames, riveted modules, or bolted assemblies. Clean datum schemes make downstream fixturing faster. The metal pressing process delivers parts that stack beautifully in bins, making automated assembly easier. With progressive dies, stamping parts can include tab formed threads, coined seats, or half shears ready for joining.

If your program requires engineered stamped components alongside machined or fabricated pieces, our team can help align the path from print to part. We integrate sheet metal stamping with machining, forming, and welding so assemblies fit the first time. Explore our custom fabrication capabilities to see how stamped features pair with precision jigs and fixtures. For a deeper view of process range, visit our fabrication services. Curious about our approach and results, including complex assemblies for mobile platforms and specialty vehicles? Learn more at why choose OZK Customs.

We work with clients who need metal stamping parts as stand alone deliverables or as components inside larger builds. From early design tweaks that prevent splitting to vendor ready drawings for the sheet metal stamping process, we translate requirements into reliable production. When you are ready to move, share your quantities, target material, and the stamping process goals, and we will outline a clear plan forward.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn a concept into production ready components or integrate stamped assemblies into a larger build? Tell us about your goals and timeline. Our team in Fayetteville can translate drawings into tooling strategies, source the right materials, and deliver consistent parts that assemble cleanly. Share your project details and we will map the smartest path from print to part.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com