Custom Fabrication

When people search for metal tube fabrication near me, they are usually balancing precision, lead time, and total cost. Quality tube work begins with clean raw material, accurate cutting, and repeatable bends that respect minimum bend radius, wall thinning, and ovality limits. Successful shops build or source the right mandrels, dies, and wipers to support the tube during bending so the cross section stays stable and weld joints land where planned. After forming, joints are prepared for welding with proper fit up, then verified, finished, and protected for the service environment.

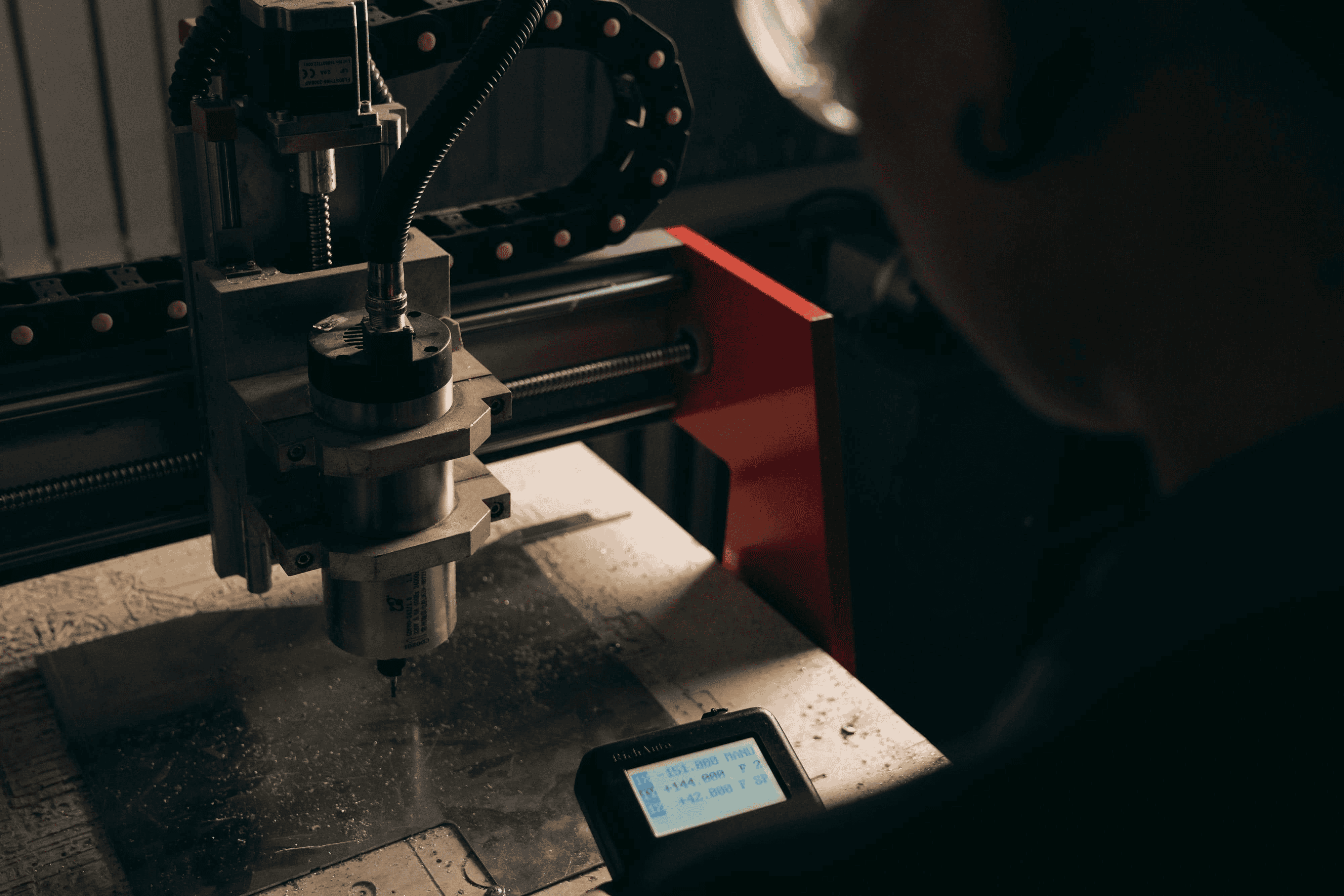

Common tubing materials include mild steel, stainless, aluminum, and chromoly, each with different springback and heat input needs. Typical operations start with saw or laser cutting, deburring, and marking, followed by rotary draw or roll bending, coping or fishmouth cuts, and welding. Engineers call out tolerances for bend angle, centerline radius, straight lengths, parallelism, and hole positions. Holding those numbers requires rigid fixtures, documented setups, and inspection tools like gauges and coordinate measurement solutions. Good process control makes custom metal tube fabrication consistent across small batches and production runs.

Rotary draw bending suits tight radii and consistent cross sections, especially with a mandrel inside the tube and wipers at the tangent. Compression bending is faster for gentle curves but offers less control over ovality. Roll bending forms large arcs across long lengths with minimal deformation, useful for frames and rails. Hot bending is rare for thin wall tubing but can help with heavy sections that would crack if bent cold. The right choice depends on diameter, wall thickness, alloy, and the required finish.

Welding choices include MIG for speed and TIG when the joint must be neat, thin, and highly controlled. Stainless and aluminum benefit from careful heat management to limit distortion and preserve corrosion resistance. Post weld finishing might include grinding, passivation, or media blasting, then coating with powder, paint, or plating. Hardware like threaded inserts, tabs, and gussets often gets added during jigging so dimensions do not drift. For parts exposed to weather or road spray, surface prep and coating specification matter just as much as bend accuracy.

Selecting metal bending services is about more than finding the closest address. Ask how the shop controls springback and verifies bend angles. Request examples of similar work and the tolerance bands they routinely hit. Clarify whether they build dedicated fixtures or rely on flexible jigs, and how they scale from prototype to repeat jobs. A capable partner can advise on design for manufacturability so parts assemble cleanly down the line.

Look for clear communication on bend radii, minimum straight between bends, and hole to bend distances that prevent deformation. Confirm they can handle your tube sizes and alloys, and whether they provide cutting, coping, welding, and finishing in house or coordinate with trusted partners. Ask for a sample inspection report so you can see how they document results against your prints.

Strong outcomes start with solid inputs. Provide dimensioned drawings with bend callouts, wall thickness, and material spec. If you have models, share STEP or native CAD files alongside PDFs so the shop avoids redraw errors. Identify critical to function dimensions and note cosmetic faces. Establish a naming scheme for revisions and keep a single source of truth for the latest file set.

Cost reflects setup time for dies, mandrels, and fixtures, then the run time for cutting, bending, welding, and finishing. Short runs often cost more per part than larger batches. Lead time depends on material availability and shop load; early conversations reduce surprises. Risk drops when you let the fabricator review tolerances and propose tweaks that cut complexity without weakening the design.

If your search for metal fabrication near me or metal tube fabrication near me needs a proven team, OZK Customs builds precise tube assemblies and welded structures in Fayetteville Arkansas. We combine accurate bending with tight welds and clean finishing so parts bolt up the first time. Our crew is used to real world demands from vehicle builds to utility structures, which means practical guidance on bend radii, joint prep, and coatings that hold up outside.

Explore our custom fabrication to see how we turn prints into ready to install parts. Review our full fabrication services for cutting, bending, welding, and finishing under one roof. Curious about our approach and workmanship standards? Learn more at why choose OZK.

Whether you need a single prototype or a steady run, our metal bending services stay focused on measurable accuracy, predictable scheduling, and clear communication. Tell us what you want the part to do, where it lives, and the tolerance stack you must hold. We will map the process, confirm the numbers, and deliver custom metal tube fabrication that fits your design and your timeline across Fayetteville Arkansas and beyond.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn sketches into steel that fits first try? Tell us about your project, timelines, and performance goals. Our team in Fayetteville Arkansas will review your prints, confirm tolerances, and propose clear next steps with transparent pricing. Submit the form to start your custom metal tube fabrication with a shop that treats every part like a final install.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com