Custom Fabrication

Metal trash receptacles used outside have a different job than their indoor counterparts. Sun, rain, freeze thaw cycles, road salt, and constant foot traffic demand tougher materials, smarter coatings, and better hardware. The goal is simple: capture litter, keep odors contained, and survive real world abuse without constant repair. That is why outdoor metal trash containers rely on thicker gauge metals, powder coated or galvanized protection, and lids that manage both weather and wildlife.

Common materials include galvanized steel for value and corrosion resistance, and stainless steel for high durability and clean aesthetics. A stainless steel outdoor trash can works well in coastal zones, pool decks, and plazas because it fights rust and cleans easily. Many sites still install a painted outdoor metal trash can in heavy use areas where color matching to site furniture matters. Either path can deliver long service when the build is right.

Outdoor metal trash containers in stainless steel resist corrosion and vandalism in public parks.

Most steel receptacles begin with cold rolled or hot dipped galvanized sheet. Galvanized layers create a barrier against moisture, and a quality powder coat adds impact resistance and UV stability. For maximum longevity, spec a zinc rich primer under the color coat and test for adequate film thickness. Where budgets allow, 304 stainless fits most urban and campus settings while 316 stainless is preferred by waterfront facilities. A stainless steel outdoor trash can with a brushed finish hides fingerprints and cleans quickly.

Open weaving, perforations, or laser cut patterns improve airflow and help liners dry after washing. Drainage holes in the base prevent standing water. Rounded edges, hemmed rims, and nylon glide feet reduce scuffs on adjacent surfaces and protect staff during servicing.

Hinged or domed lids shed water and block wind blown debris. Side door access with a commercial latch lets staff change liners without lifting a heavy top. Fire containment features such as sand trays or restricted openings help extinguish smoldering waste. In urban cores, critter resistant doors and cigarette management tops reduce mess. If the site is breezy, look for integrated bag retention rings and retainer clips so a metal trash can outside will not release liners on gusty days.

Receptacles should consider accessibility. A door swing or opening height that meets reach ranges eases use for everyone. Clear iconography and color bands reduce contamination when pairing waste and recycling streams. Split stream housings can sort landfill, bottles, and paper in one footprint.

Getting the size right matters. A busy trailhead or food court can fill a 32 gallon unit quickly, while a quiet sidewalk may only need 20 gallons. Larger 45 to 55 gallon bodies cut service trips but require heavier liners. Coordinate internal liners in polyethylene or rigid steel with a smooth rim to prevent bag tears.

Weight and anchoring are core to performance. Steel trash cans outdoor often include base plates with anchor points for concrete pads. In parks, hidden brackets or ground spikes keep units upright yet removable for seasonal changes. For sidewalks near traffic, anti tip design and a weighted base improve stability. Consider snowplow clearance in northern climates and set back from curbs to avoid damage.

Maintenance plans should address graffiti, stickers, and winter salt. Powder coats with anti graffiti clear coats clean faster. In coastal regions, rising salt spray makes stainless the smart long term choice, even if the upfront cost is higher. Routine washdowns with mild soap protect finishes and keep logos vibrant.

Public furniture must expect rough handling. Look for recessed fasteners, tamper resistant hardware, and shielded hinges. Welds should be continuous where feasible and ground smooth to shed moisture. Side access doors with slam latches shorten liner swaps and reduce strain injuries. A well designed metal outdoor dustbin will protect branding plates and keep QR asset tags readable for facilities teams.

Start by mapping foot traffic, food service zones, and wind paths. Put receptacles at decision points such as exits, bus stops, and seating clusters. Match capacity to the expected load and coordinate colors with benches, bike racks, and lighting for a cohesive streetscape. If you need recycling, select multi stream tops with clear aperture shapes that match the material.

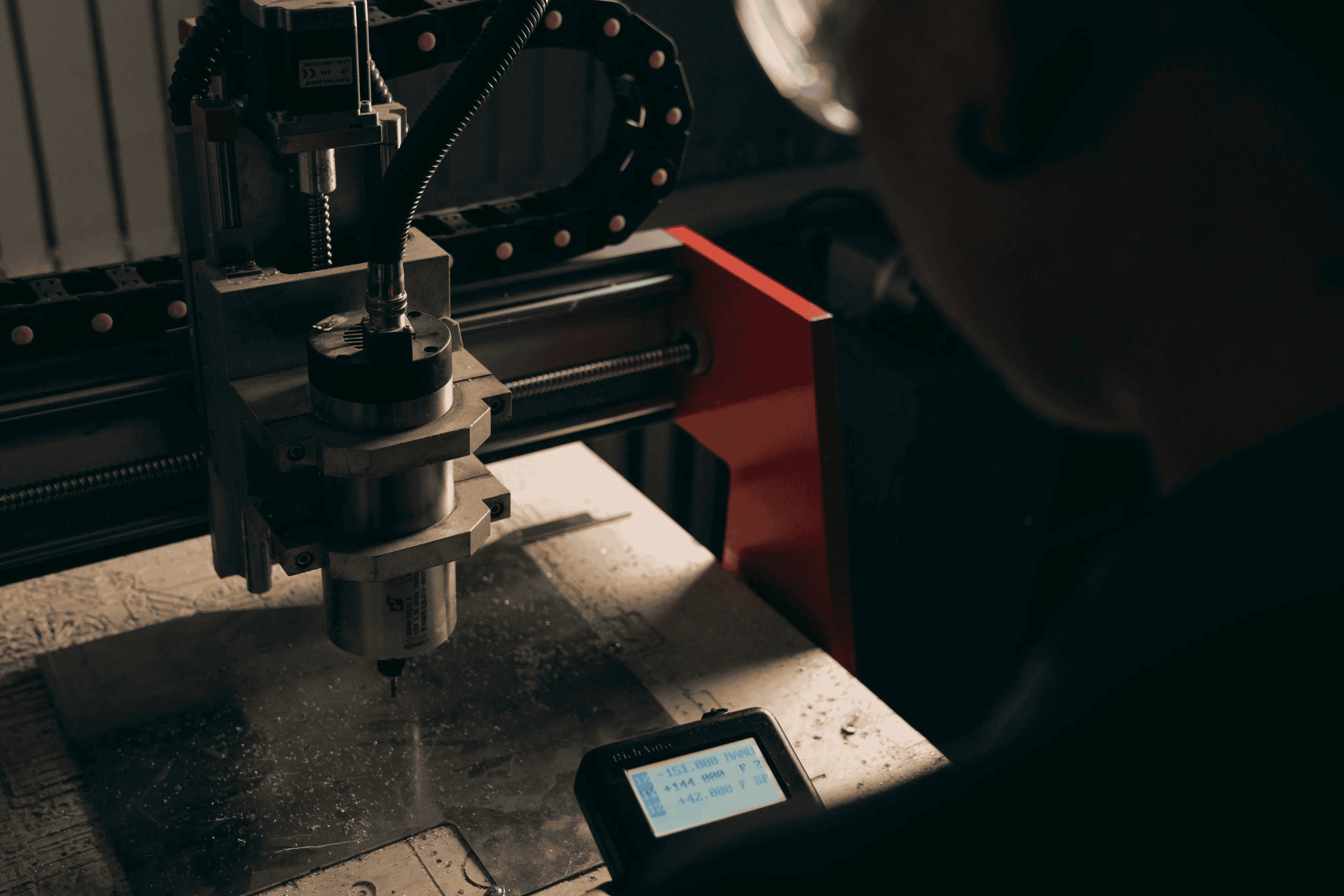

Some locations have unique needs. You might need bear resistant doors, ADA tailored reach heights, or a footprint that fits a narrow plaza. That is where custom work shines. Our team builds site furniture in steel and stainless to match exact dimensions, liners, and finishes. Explore our Custom fabrication to see how we tailor housings, lids, and anchoring to your environment. If you prefer a more detailed breakdown of processes, materials, and joinery, review our Fabrication services. Curious about our standards, handoff process, and client experience across public projects and commercial sites? Learn more at Why choose OZK Customs.

Tell us how your receptacles will be used, cleaned, and anchored, and we will design a steel or stainless solution that aligns with your maintenance program and budget. From powder coated galvanized bodies to marine grade stainless housings, we engineer for weather, wear, and daily service. Share your capacity target, lid style, and branding needs and we will build a metal trash receptacle that looks right on day one and still works years later.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to spec or build a steel or stainless receptacle that fits your site, brand, and budget? Tell us your dimensions, capacity, and finish needs. OZK Customs will design and fabricate a solution that handles weather, wear, and daily service with ease.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com