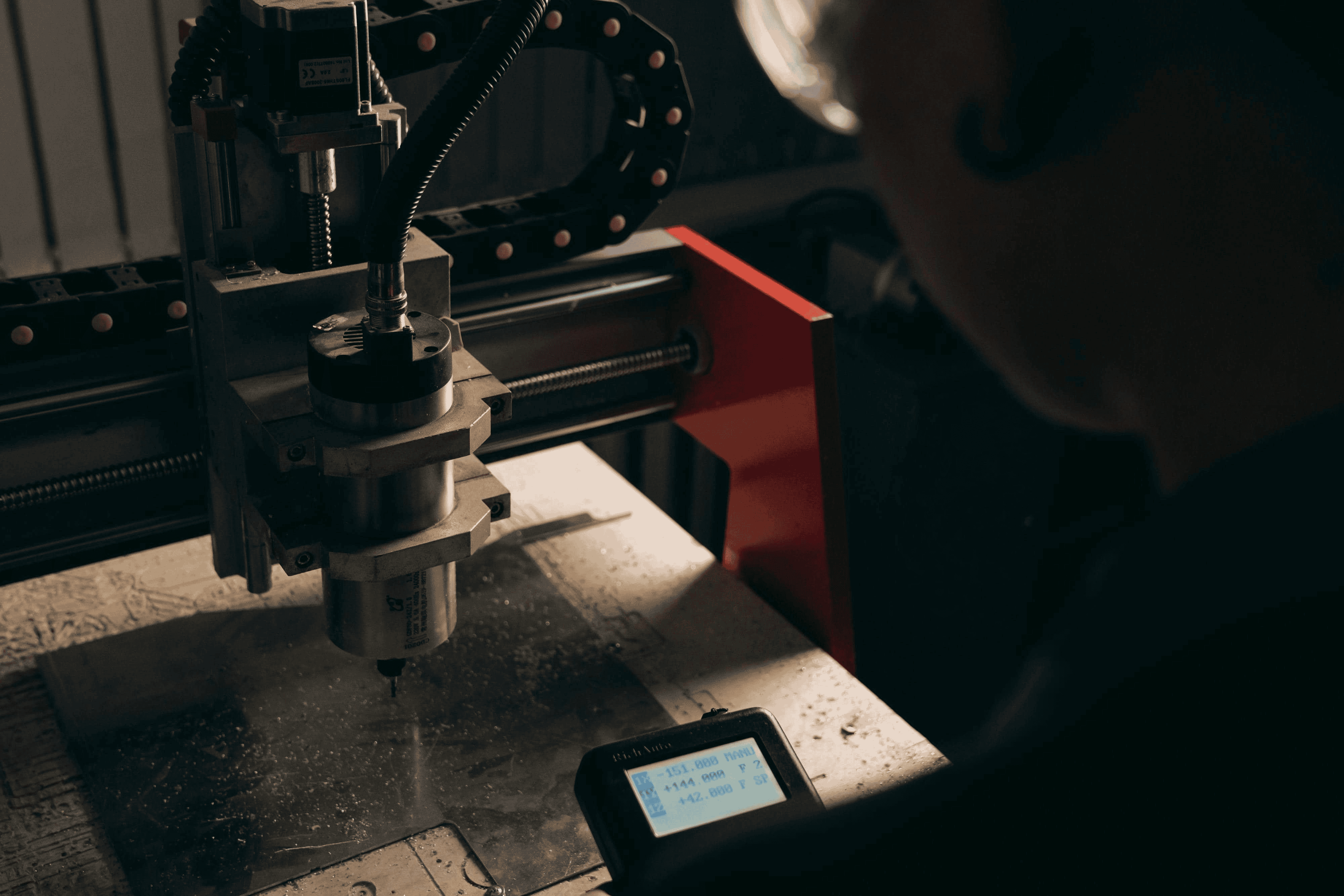

Custom Fabrication

Metal picnic tables are a staple in parks, campuses, and trailheads because they resist wear, clean quickly, and hold up under constant use. Most frames and tops use steel tubing or expanded steel for strength and drainage, with designs that shed water and deter vandalism. The real difference maker is the finish. Coatings protect the substrate from rust, abrasion, and sunlight while shaping the texture users feel every day.

Plastic coated picnic tables deliver a thick, seamless shell over the steel that seals moisture out and softens edges. When the substrate is steel, you will see them described as plastic coated steel picnic tables or plastic coated metal picnic tables. The coating is usually polyethylene or plastisol applied with generous thickness, which cushions impact and shrugs off chips better than thin paint films. Thermoplastic coated picnic tables perform similarly, using heat bonded material that builds a sturdy layer with color that runs through the coating, not just on the surface.

Powder coated picnic tables use electrostatically applied powder cured into a continuous film. The result is crisp color, good chemical resistance, and straightforward touch ups if a scratch happens. Though thinner than plastic layers, quality powder over a galvanized base offers a reliable balance of durability and design flexibility. Rubber coated picnic tables and rubber coated metal picnic tables add a grippy, comfortable feel, especially helpful on edges and seat fronts where comfort matters in colder weather. These coatings can also dampen noise when items set down on the tabletop.

Coated picnic tables should be evaluated by the coating thickness, adhesion, UV stability, and the corrosion protection beneath the color. Galvanized steel, zinc rich primer, or both, act as a backstop when the outer layer gets scuffed. Coated metal picnic tables that combine a corrosion resistant base with a high performance shell last longer between maintenance cycles and keep colors truer through seasons of sun and rain.

Steel remains the workhorse for frames and tops thanks to strength, weldability, and stable pricing. Expanded steel and perforated steel tops allow airflow and fast drying, reducing puddles and debris buildup. Aluminum appears in some designs for lighter weight and natural corrosion resistance, although it benefits from coating for color and extra surface protection. Look for reinforced seat braces, cross members that resist racking, and mounting plates sized for concrete or soil anchors to keep the table planted.

Plastic and thermoplastic systems build a rugged shell measured in mils, making them ideal when carts, skateboards, or maintenance equipment share the space. Powder offers a smooth surface that wipes clean and allows fine color matching across site amenities. Rubber style coatings emphasize comfort and grip, which can be useful in cooler regions where bare metal feels cold to the touch. Always confirm the coating’s UV package, salt spray performance, and graffiti removal compatibility to match real world use.

Most coated picnic tables need simple care: rinse grit, use mild detergents, and avoid harsh abrasives. Inspect high contact zones a few times each season for chips or cuts. Powder coated surfaces can be spot repaired with compatible touch up paint. Thick plastic layers often tolerate more abuse before needing intervention, and many allow heat based repairs by a professional. The combination of quality substrate prep, sound welds, and the right coating is what ultimately determines lifespan.

For anchoring, embed hardware in concrete pads or use tamper resistant ground stakes. Confirm table dimensions meet accessibility standards, including knee clearance and an accessible seat position. Add protective caps on exposed fasteners to prevent rust stains around bolt heads.

Before you finalize a spec, lock in a few essentials:

If your site needs custom colors, brand accents, integrated signage, or specialty dimensions, OZK Customs can help. Our team designs and fabricates metal components, builds to spec, and finishes parts for tough outdoor environments. See our Custom fabrication for metal, review our Fabrication services, and learn more at Why choose OZK Customs. Share your site plan and usage profile, and we will recommend the right coating and structure so your tables hold up through seasons of sun, storms, and daily crowds.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to spec a table that actually survives your climate and daily traffic? Share your site, budget, and finish requirements. OZK Customs will engineer, fabricate, and finish to your standards, then deliver a rugged setup that looks right and lasts.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com