Custom Fabrication

Metal fabrication parts and roll bar fabrication parts installed on a custom van in Fayetteville Arkansas for safe off road performance.

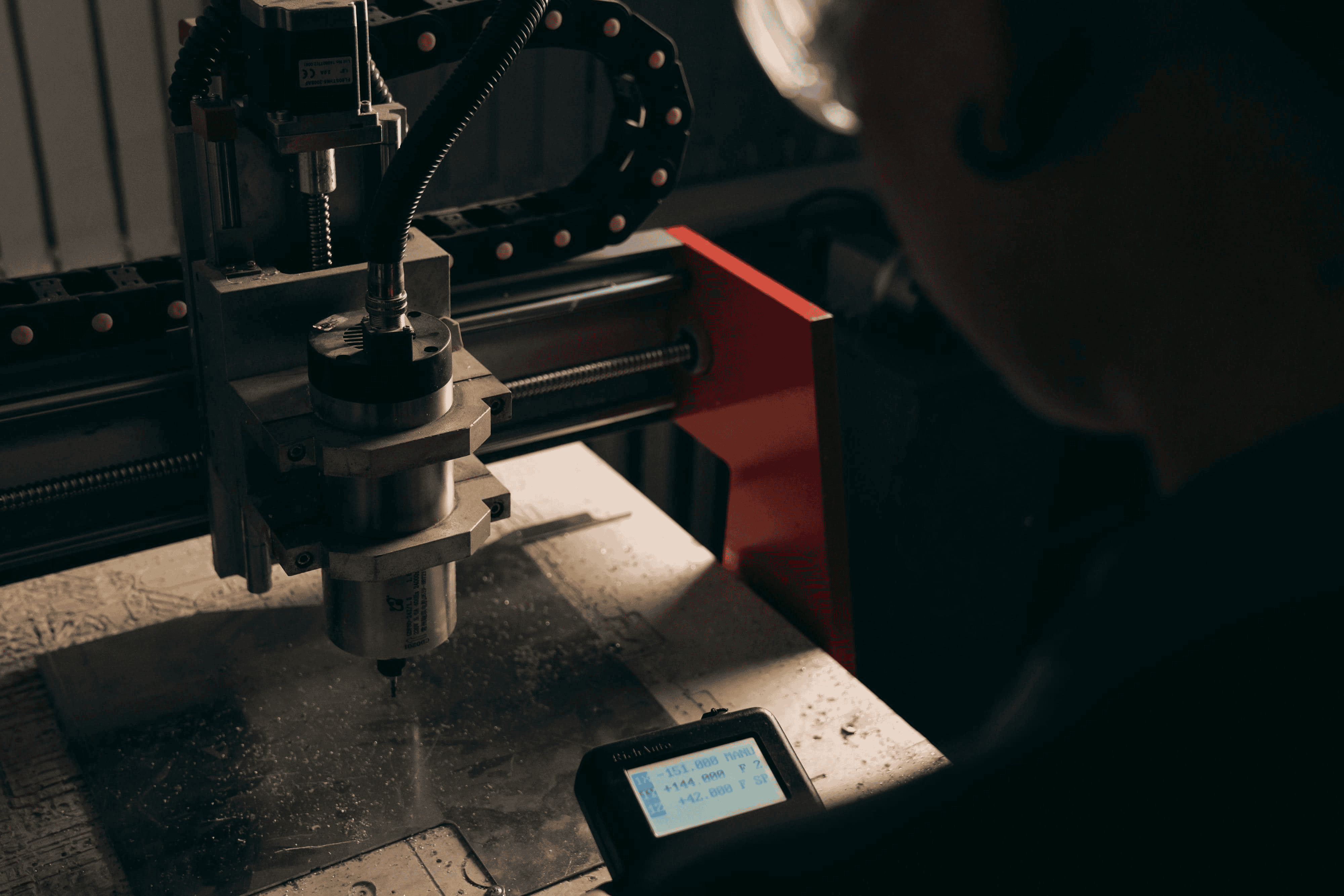

Metal fabrication parts are the building blocks of strength and precision in a vehicle. Brackets, tabs, gussets, tube clamps, base plates, and formed panels turn raw material into structure. The fundamentals are simple to list and easy to miss in practice. Material choice, accurate cuts, clean bends, tight tolerances, and controlled heat input are what separate dependable components from shelf fillers.

Common alloys include mild steel for adaptable welding and forming, chromoly for high strength to weight, stainless for corrosion resistance, and aluminum for light weight panels and non structural elements. Each material responds differently to bending, notching, and welding, so tooling and technique need to match. Plasma, laser, or waterjet can produce clean edges when paired with correct kerf compensation and post processing. Press brakes should deliver crisp, repeatable angles without over thinning the bend radius.

Quality is visible in details. A properly notched tube seats against its mate with full contact. A gusset follows the load path rather than just filling space. Holes are sized for the fastener shank and shoulder, not just the thread. Parts that are square, flat, and deburred install faster and last longer.

For structural tubing, look at diameter, wall thickness, and specification. Drawn over mandrel steel offers good consistency and weldability. Chromoly reduces weight for the same stiffness but calls for careful heat control and post weld treatment. Cutting and forming methods matter as well. Tube bends should be wrinkle free with consistent outside diameter and minimal springback. CNC cutting gives accurate repeats, and calibrated fixtures ensure symmetry from left to right components.

Good design reduces stress concentration and spreads loads smoothly. That shows up as larger base plates with proper backing, radiused gussets instead of sharp corners, and joints that avoid thin heat affected zones. Bolt holes should be spaced to prevent tear out, and welds should be placed where the joint sees shear rather than peel. Pay attention to how parts meet the chassis. Unibody vehicles may require reinforcement to tie into factory hard points safely.

Dry fit before welding or final torque. Clean mill scale where welds will go. Use the correct fastener grades and lengths, and never rely on sheet metal alone for main load paths. Where possible, pair bolts with backing plates and crush sleeves to maintain clamping force. Once installed, mark fasteners and set a schedule to recheck torque and inspect welds after the first few hundred miles.

Roll bar fabrication parts and roll cage fabrication parts raise the bar for selection and inspection. Critical items include main hoop tubing, halo and A pillar tubes, base plates, cross braces, harness bars, diagonal braces, node gussets, and tube clamps. The system must work as a unit, not as a collection of pretty pieces.

Motorsport bodies publish minimums for tubing size and material, and even if you are not racing, those specs offer a reliable baseline. Bracing geometry matters. Diagonals prevent rhombus shaped distortion, and harness bars need correct height and angle to support belts. Base plates should spread load into floor structure or frame rails with reinforcement beneath. Removable joints require high quality clamps or sleeves with proper plug welds and bolts sized to carry shear loads.

Aim for continuous load paths from roof to floor, and from front to rear. Keep nodes simple and direct. Avoid placing welds near tight bends. If the build targets a sanctioning rulebook, verify tube sizes, bend angles, and mounting plates ahead of time to prevent rework. For trail focused rigs, consider head clearance, seat travel, and visibility along with strength.

A good process starts with measurements and modeling. CAD and, when available, scanning help produce tight fitting notches and bends, reduce waste, and speed repeatability. Jigs hold orientation so both sides match. Weld sequencing minimizes distortion and keeps parts true. After fabrication, finishing protects and beautifies. Powder coat offers durable coverage, e coat reaches hidden cavities, and paint allows quick touch ups. Stainless may need only a brushed finish if weight and cost make sense.

Surface prep is where finishes earn their keep. Clean edges, proper blasting profile, and contamination free surfaces lead to coatings that resist chips and weather. For daily drivers and off road builds, choose coatings that balance durability with serviceability so touched areas can be repaired without stripping the entire part.

Ongoing maintenance keeps the system ready. Check fastener marks, inspect weld toes for cracks, and watch for coating damage at high impact points. Update documentation with any changes so future service techs know what materials and processes were used.

When you are ready to turn plans into parts, our team in Fayetteville Arkansas can handle the entire chain from design to install. Explore our custom fabrication services to see how precision work and thoughtful engineering come together. For a deeper look at tools, processes, and materials, review our fabrication capabilities. Curious about our approach, shop culture, and client experience. Visit Why choose OZK Customs and see how we build for performance and peace of mind.

Tell us about your vehicle, use case, and timeline. We can craft metal fabrication parts, roll bar fabrication parts, and roll cage fabrication parts that fit precisely and stand up to real roads and real trails. From first concept to final torque, we will guide the process so you get a safer, cleaner build without surprises.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready for parts that fit right, weld clean, and hold strong when it counts. Tell us about your vehicle and goals. OZK Customs designs, fabricates, and installs precision metal components and full protection systems in Fayetteville Arkansas. Fill out the form and let’s engineer a solution that meets your timelines, budget, and safety standards.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com