Custom Fabrication

Metal bike racks succeed or fail on three fundamentals, structure, finish, and fit. Structure is all about geometry and wall thickness, not just the alloy. Steel tube with thoughtful bracing resists racking forces from heavy e bikes and mountain rigs. Aluminum reduces weight and resists corrosion, but needs proper section sizing to avoid flex. Stainless brings corrosion resistance for coastal or high humidity spaces, though it comes at a higher cost.

Finish is the barrier between your rack and real life. Powder coat stands up to abrasion and minor impacts better than basic paint. For outdoor exposure, zinc rich primer under powder coat improves longevity. Galvanized steel remains a solid option for high salt environments, especially when aesthetics are secondary to service life.

Fit is the day to day experience. Tire channels or cradles must accept common sizes, from skinny road tires to plus and fat rubber. Hook styles should avoid sharp edges that mark rims. Spacing matters. Center to center gaps of 16 to 24 inches prevent bar and pedal contact, especially with wide bars. Consider e bike weights when specifying load limits, many modern bikes weigh 50 to 70 pounds.

Rolling bike rack and metal bike rack stand organized for shop storage

A rolling bike rack solves a common problem. You need storage and you also need open floor space on demand. The wheels make the difference, and not all casters are equal. Look for a total load rating that exceeds the combined weight of bikes and rack, then add a buffer. Locking casters on at least two corners keep the rack steady while loading and unloading. Larger wheel diameters roll easier over thresholds and rough concrete, while softer tread materials reduce vibration and noise.

Stability on the move comes from a low center of gravity and wide stance. If the rack holds bikes high, counter that with a wider base or diagonal bracing. Swivel casters make tight turns possible, but too many swivels can feel twitchy. A blend of fixed and swivel wheels gives predictable handling in narrow aisles. For floors that collect dust or trail debris, sealed bearings help keep the motion smooth.

Safety is not a luxury. Add tie points for straps if you plan to move loaded bikes across uneven floors. Avoid sharp corners near walk paths and use capped ends on tube sections. If you store in a shared space, bright color accents improve visibility without shouting.

Choose between single side access for wall adjacency or double side access for central placement. Vertical hanging maximizes density, while horizontal cradles simplify loading for heavy bikes. Modular bays let you scale as your fleet grows.

The tightest spacing wins on paper but slows real life use. If you grab bikes daily, leave more elbow room. If you store seldom used gear, a denser array makes sense.

If you intend to roll with bikes on board, specify stronger casters and reinforce the frame. Test the turning radius with your widest bar width before finalizing dimensions.

A metal bike rack stand anchors your system. Whether bolted to concrete or designed to sit solidly on rubber feet, the stand should feel planted. Floor plates with multiple anchor points distribute loads without cracking the slab. For portable stands without anchors, a longer footprint and cross bracing keep the structure steady under side loads.

Security features change the equation. Integrated loops that accept U locks allow quick locking without awkward angles. If you store outdoors, consider closed tube sections that deter tampering and fasteners that are not easily removed. Indoors, rubberized contact points protect paint and components.

Finish selection again ties to environment. Indoors, durable powder coat resists shop wear. Outdoors, hot dip galvanizing followed by a color topcoat extends service life. In damp basements or coastal regions, stainless fasteners prevent galvanic issues with coated steel frames.

Confirm bar width, wheelbase range, and tire widths for your fleet. Through axle adaptors or wider cradles may be needed for modern mountain and gravel bikes.

Even a freestanding stand benefits from a discreet wall bumper to prevent scuffs. For wall connected designs, use proper anchors matched to the wall substrate.

Inspect casters, anchors, and contact points with a seasonal checklist. Tighten hardware, replace worn feet, and touch up finish before corrosion takes hold.

Start with a simple map of your room, measure clearances, and trace common walking lines. Decide where you need maximum density and where fast access matters. If bikes roll in dirty, create a landing zone with mats before storage. Add lighting above the rack so you can load safely at night. For shared shops, label positions to speed up returns and keep the flow orderly.

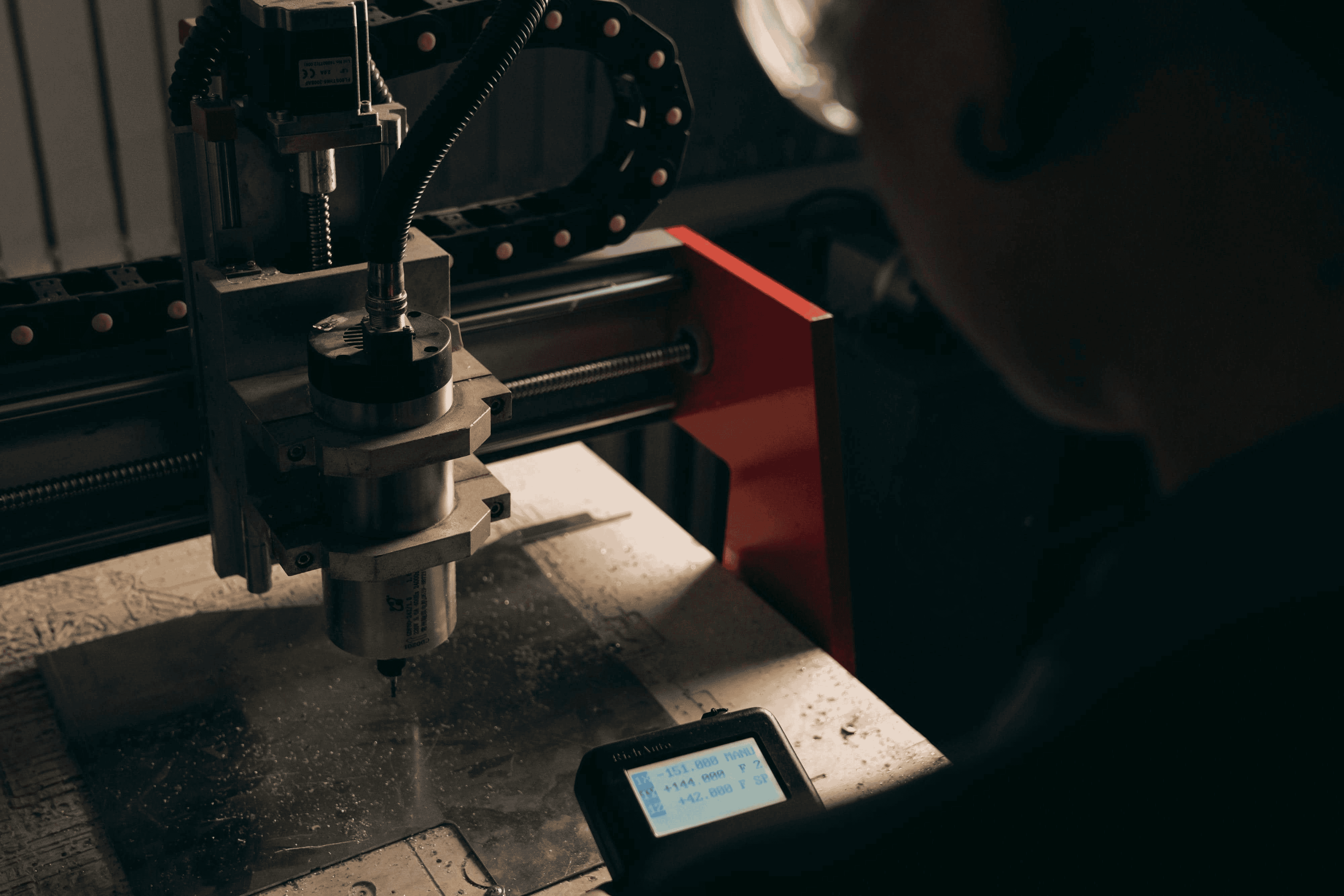

When you are ready to turn a sketch into steel, precision matters. OZK Customs builds metal bike rack solutions that match your bikes, floors, and daily routine. Our team fabricates rolling systems and stand based storage with the right mix of structure, finish, and fit for long service life in real world conditions. Explore our custom fabrication, review the range of fabrication services, and see what sets us apart at why choose OZK. Whether you need a compact metal bike rack stand for a home garage or a high capacity rolling bike rack for a busy shop in Fayetteville, we will design and fabricate a solution that works hard and looks right.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready for a rack that fits your exact space, fleet, and workflow? OZK Customs designs and fabricates metal bike racks that roll smoothly, stand solidly, and last. Tell us about your bikes, footprint, and security goals. We will blueprint the right solution and build it with precision.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com