Custom Fabrication

Sheet metal bending transforms flat stock into angles, channels, and complex profiles without removing material. A press brake aligns a punch and die to form the bend line while clamping pressure and tonnage shape the metal. Accuracy depends on precise tooling, consistent material thickness, and the selected bending method. Tool radius and die opening influence bend allowance, springback, and minimum inside radius, which all determine how closely a final part matches the drawing.

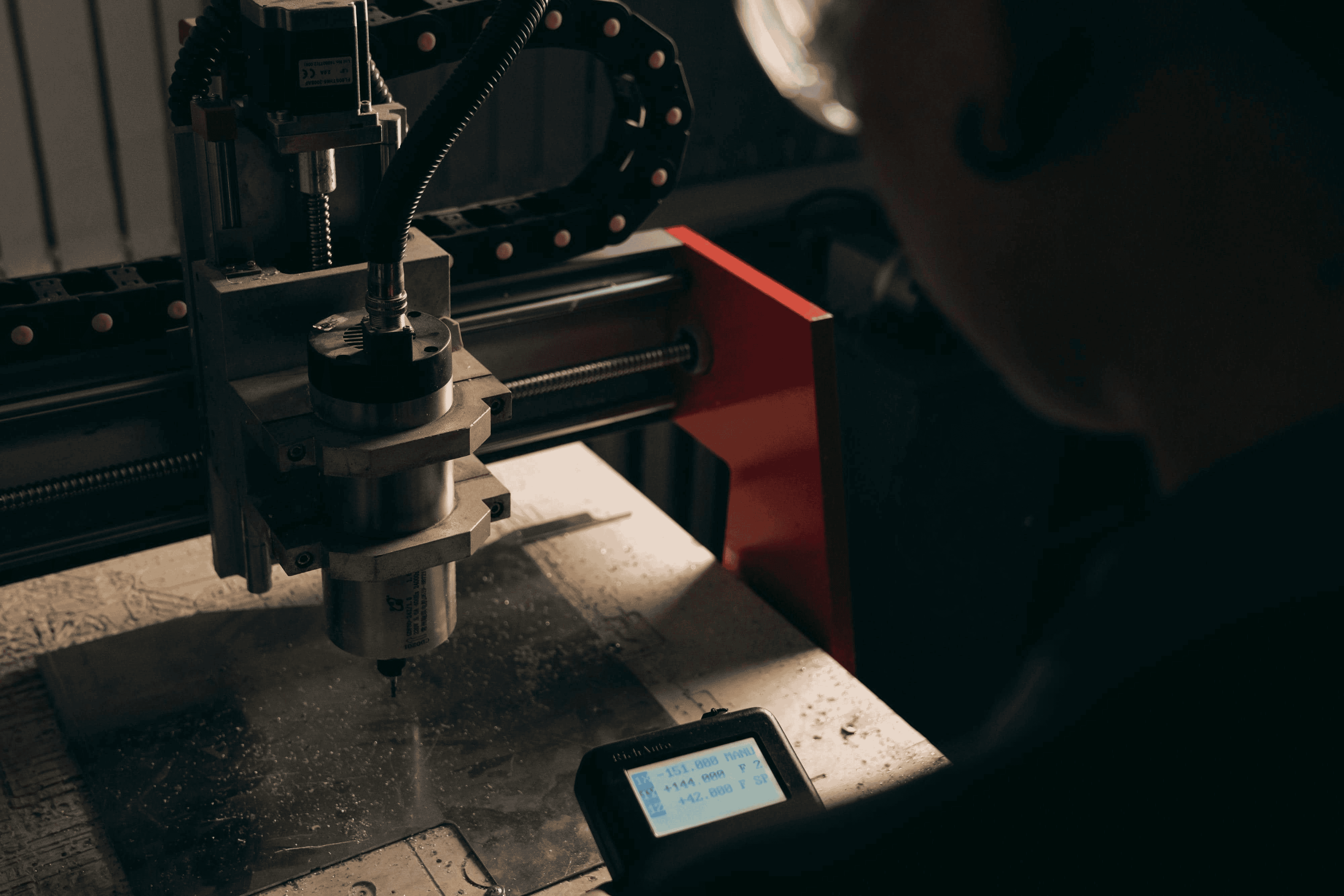

Sheet metal bending services and laser cutting on stainless steel parts for consistent angles and clean edges

Air bending, bottoming, and coining are the three common techniques for sheet bending. With air bending, the punch does not fully seat the material into the die, which allows flexible angle control but increases springback. Bottoming drives the material into the die to a defined angle, reducing springback and improving repeatability. Coining compresses the bend line at higher pressure to imprint the punch radius, producing very tight angles and minimal springback at the cost of higher tonnage and more tool wear.

Material behavior shapes every decision. Mild steel is forgiving and supports tight inside radii relative to thickness. Bending stainless steel sheet metal requires larger radii because stainless work hardens quickly and resists deformation. Aluminum bends easily but can crack if the inside radius is too small. Grain direction matters as well. Bending across the grain reduces cracking risk, while bending with the grain can require a larger radius to prevent fractures in a bent metal sheet.

Thickness and die selection go hand in hand. A common starting point for V die opening is eight times material thickness for air bending. Tooling charts and manufacturer data refine this rule for steel sheet bending and aluminum variants. Press brake tonnage calculations account for material type, tensile strength, and die opening, preventing deflection that would otherwise distort angles and flange lengths.

Designers should plan for bend allowance and bend deduction. The neutral axis shifts during bending, so flat patterns must include compensation to produce accurate finished dimensions. Springback correction is another constant. Softer alloys show less springback, while higher strength materials require overbending to hit the target angle. Practical checks like test coupons confirm calculated values before a production run.

CNC sheet metal bending pairs programmable angles with controlled backgauge movement, producing repeatable flange lengths in fast cycles. Multi axis backgauges support staged bends and complex sequences that limit material handling. Tool libraries store punch and die combinations, while offline programming builds bend sequences that avoid collisions and maintain datum references.

Angle sensors and crowning systems correct for press brake deflection, particularly on long parts where the center can drift from spec. Quality checks focus on angle tolerance, flange length, and surface finish at the bend line. When a drawing calls for tight flatness or perpendicularity, consistent tooling height, proper shimming, and correct crowning help hold those numbers. For aesthetic parts, using a larger nose radius reduces marking and preserves surface coatings.

Tolerances must be realistic. As angles tighten and tolerances shrink, forming becomes sensitive to batch variations in material thickness and tensile strength. Standardizing suppliers and documenting actual material data builds predictability. For stainless, using a larger inside radius and careful tool pressure minimizes galling and micro cracking, protecting both the part and the tooling.

Metal laser cutting services and forming complement each other. Clean, consistent kerf and minimal burr allow accurate gauging in the press brake. Precise cut geometry sets reliable bend locations, especially for tabs, slots, and reliefs that guide forming. Fiber lasers excel on stainless and thin gauge steel, delivering tight tolerance blanks with limited heat affected zones. When a part demands cosmetic edges or intricate features, laser cut blanks create predictable results at the brake.

Edge quality affects form. A rough or heat distorted edge can change springback and affect the neutral axis. With controlled cutting parameters, the bend responds as expected and angle corrections remain stable across a batch. For complex parts, combining cutting and forming in a single workflow keeps datum references consistent and reduces scrap.

When the job calls for repeatable sheet metal bending across multiple materials, pairing precise laser cut blanks with dialed in forming programs shortens setup time and improves first article success. This is especially true for steel sheet bending and bending stainless steel sheet metal where material properties can shift angle outcomes.

OZK Customs offers end to end metal bending services and laser cutting that follow these process principles. Our team programs flat patterns, selects tooling for your alloy and thickness, and validates bend allowances with test pieces before production. Explore our custom fabrication capabilities, review the range of fabrication services we provide, and learn more about our approach on why choose OZK.

From prototypes to production, we cut, form, and finish parts that fit the first time. Whether your scope is cnc sheet metal bending, complex laser cut features, or both, we align tooling, material selection, and inspection to your tolerance goals. Share your drawings and desired outcomes, and we will create a process plan that turns flat stock into accurate, repeatable components.

We're happy to talk specs, fitment, or just bounce ideas around.

Need tight tolerance bends and clean cut edges on your next run of parts? OZK Customs delivers CNC press brake forming and in house laser cutting for stainless, steel, and aluminum with fast quoting and consistent results. Share your prints and required tolerances, and we will produce parts that fit on the first try.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com