Custom Fabrication

Metal forming services reshape material through force rather than cutting, preserving grain structure and strength while delivering precise geometry. The work relies on dies, presses, rollers, and dedicated fixtures that guide the metal as it bends, stretches, or compresses. A sheet metal forming machine can be mechanical, hydraulic, or servo driven, each offering different control over speed, tonnage, and position for repeatable results. When selected properly, sheet metal forming equipment helps reduce waste, lower per part cost, and shorten lead times for both prototypes and production runs.

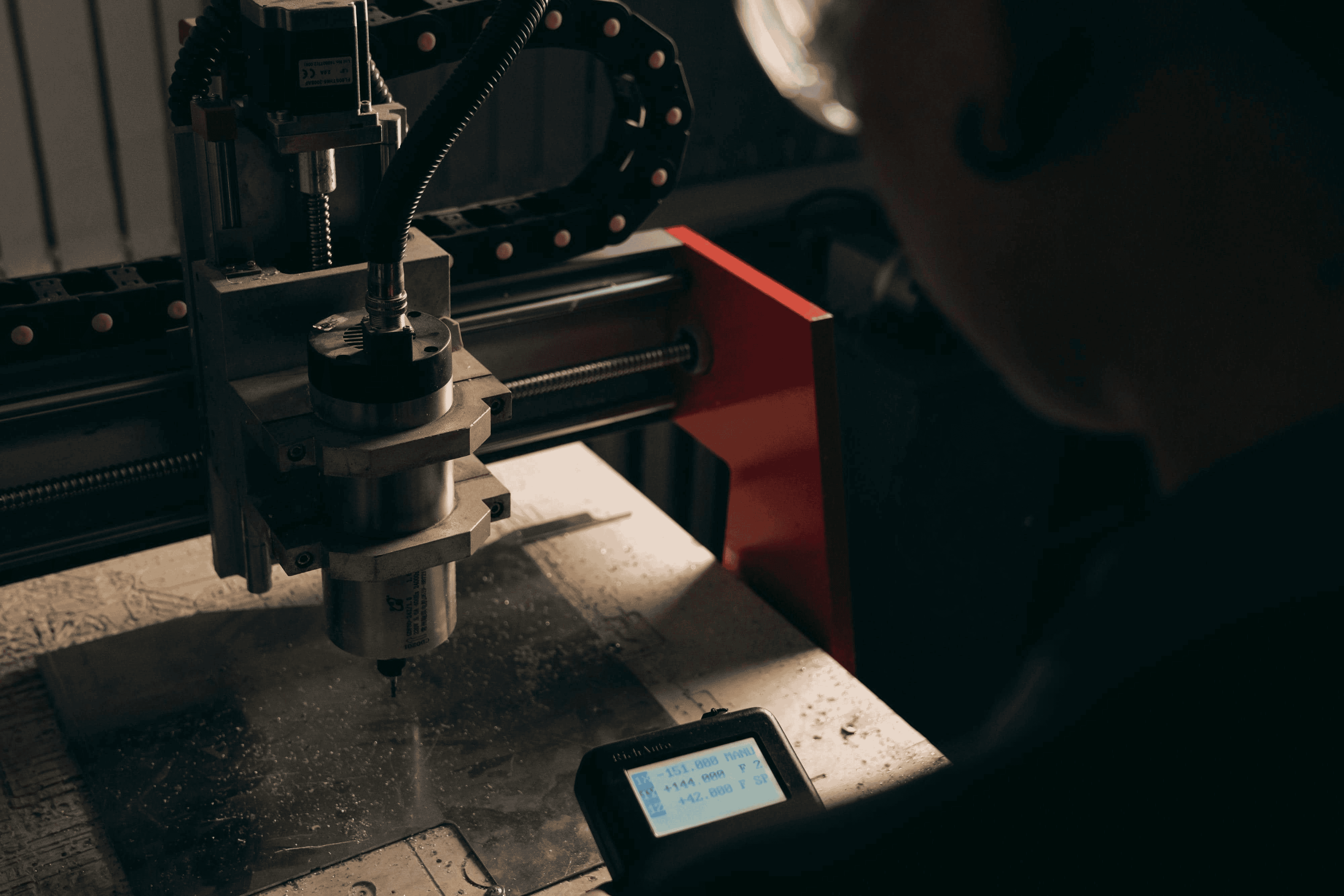

Sheet metal forming machine and equipment shaping an aluminum panel with precision tooling inside a custom fabrication shop in Fayetteville.

Common methods include bending, stamping, deep drawing, roll forming, spinning, and hydroforming. Bending controls angle and radius with matched punches and dies while accounting for springback. Stamping and deep drawing form complex contours using progressive dies and blank holders that prevent wrinkling. Roll forming creates long consistent profiles with a series of calibrated stands. Hydroforming uses fluid pressure to push material into a die, enabling smooth, seamless shapes with excellent surface finish.

Modern metal forming technology extends beyond presses. It includes servo drive controls for precise motion, optical measurement for inline verification, and simulation tools that predict thinning, wrinkling, and failure zones before a die is cut. With good data and the right metalforming tools, teams can dial in formability and cut iterations on the shop floor.

Selecting a sheet metal forming machine begins with part geometry, alloy, thickness, and production volume. Complex shapes with tight radii often benefit from servo press control and staged operations to manage strain. Long channels or architectural profiles may favor roll forming for consistency and speed. If the part needs deep cavities or seamless transitions, hydroforming or multi step draw operations can maintain wall thickness while protecting the surface.

Tooling makes or breaks a forming operation. Die materials and surface treatments reduce galling and heat buildup, especially with stainless and aluminum. Accurate dies, carefully designed draw beads, and polished radii manage friction and material flow. Good fixturing prevents chatter and keeps angles true. For short runs, modular, quick change setups reduce downtime. For production, dedicated progressive dies and automated feed systems raise throughput and stabilize quality.

Quality hinges on controlling springback, thinning, and edge integrity. Process engineers measure bend allowance, select proper inside radii, and use compensation strategies to hit nominal dimensions. Non contact scanners and go or no go gauges confirm profiles. When a forming machine metal operation combines robust fixturing, calibrated tonnage, and real time inspection, tolerances tighten and rework drops. The result is consistent fitment with clean bends, smooth curves, and holes that align during assembly.

Every alloy reacts differently. Aluminum tends to spring back more than mild steel, while high strength steels demand larger bend radii to avoid cracking. Grain direction affects bend performance, so blanks are oriented to favor the tightest bends. Forming limit diagrams and simulation highlight safe strain regions and help teams choose draw steps, bead locations, and lube strategy. Designers who consider these factors early can avoid unnecessary secondary machining and keep parts both light and strong.

Thoughtful design for manufacturability also considers hemmed edges, relief cuts near sharp transitions, and hole placement away from high strain zones. By planning for the capabilities of sheet metal forming equipment, projects maintain a clean surface finish and structural integrity while meeting cosmetic expectations.

Safe forming setups use interlocks, light curtains, and well marked operator zones. Speed comes from minimizing tool changes, using coil or sheet feeders, and aligning press capacity to part size. Cost efficiency is achieved by matching process to volume, investing in the right dies, and reducing scrap through better nesting and accurate blanks. Over time, the upfront investment in sound tooling pays for itself in fewer defects and faster assembly downstream.

If your project needs prototype brackets, panel systems, or structural components, an integrated shop can combine design insight with reliable execution. Complex builds often require more than forming alone, including laser cutting, CNC routing for non metal components, and precision welding to finish assemblies. A partner that understands design for forming can help you lock in the process, validate tolerances, and scale without surprises.

OZK Customs provides a full spectrum of forming and build support inside a modern custom fabrication shop. Our team pairs accurate cutting with precise bending, drawing, and fixturing so parts fit the first time. When your project calls for specialized setups, our in house fabrication services handle tooling, prototypes, and small batch runs before scaling.

We back this with transparent communication and a process built for real world timelines. Learn more about our approach and how we treat every build like a mission by visiting why choose OZK Customs.

Bring your drawings, a sample part, or even a sketch. We will review the best path using a sheet metal forming machine, the right metalforming tools, and the most suitable sheet metal forming equipment to achieve your goals with dependable quality. Share your project details and we will turn them into consistent, production ready parts.

We're happy to talk specs, fitment, or just bounce ideas around.

Bring your concept and leave with production ready parts. Submit the form and our team will review your drawings, recommend the right forming approach, and quote fast so your build stays on schedule.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com