Custom Fabrication

When people search welding shop near me, they are usually comparing skill, speed, and repeatable quality. Look for shops that publish material specialties, common tolerances, and inspection methods. A capable team will handle stainless, aluminum, and carbon steel, and will explain when to use TIG or MIG based on thickness, finish, and strength needs. Ask to see sample welds across multiple materials and positions, along with photos of finished assemblies to judge consistency.

Cleanliness and prep drive results. For stainless steel welding near me, contamination control prevents discoloration and pitting. For aluminum fabrication near me, oxide removal and tight gas coverage reduce porosity. Expect the shop to outline heat input control, fixture strategies to manage distortion, and how they verify critical dimensions. If they can talk through weld symbols, joint design, and finishing steps in plain language, you are in good hands.

Stainless welding near me often means sanitary, corrosion resistant, or architectural work. TIG is the common choice for precision beads on 304 or 316, especially when appearance matters. Back purging with argon protects the root side on tubing and thin sheet, minimizing sugar and preserving corrosion resistance. After welding, passivation or pickling restores the chromium rich surface, helping the part resist rust in kitchens, breweries, marine settings, or high humidity environments. Ask for documentation on surface finish and any post weld treatment so your parts perform as intended.

Aluminum demands careful technique because the oxide layer melts at a higher temperature than the base metal. AC TIG breaks that oxide and provides fine puddle control for thin parts and visible seams. Pulse MIG is efficient on thicker sections and can limit heat input while maintaining deposition. Look for shops that discuss filler selection for 5052 or 6061, preheating on heavy sections, and fixturing to reduce warping. If you need powder coat or anodize, confirm how the team prepares surfaces to ensure even finishes without trapped contaminants.

Start with certifications and process control. Many reputable teams work to AWS standards for structural, aluminum, or sanitary applications. Ask about written procedures, welder qualifications, and what inspection steps they use, such as visual inspection under proper lighting, dye penetrant for stainless, or fit checks on a fixture. Good shops are proud of their inspection flow and will walk you through it.

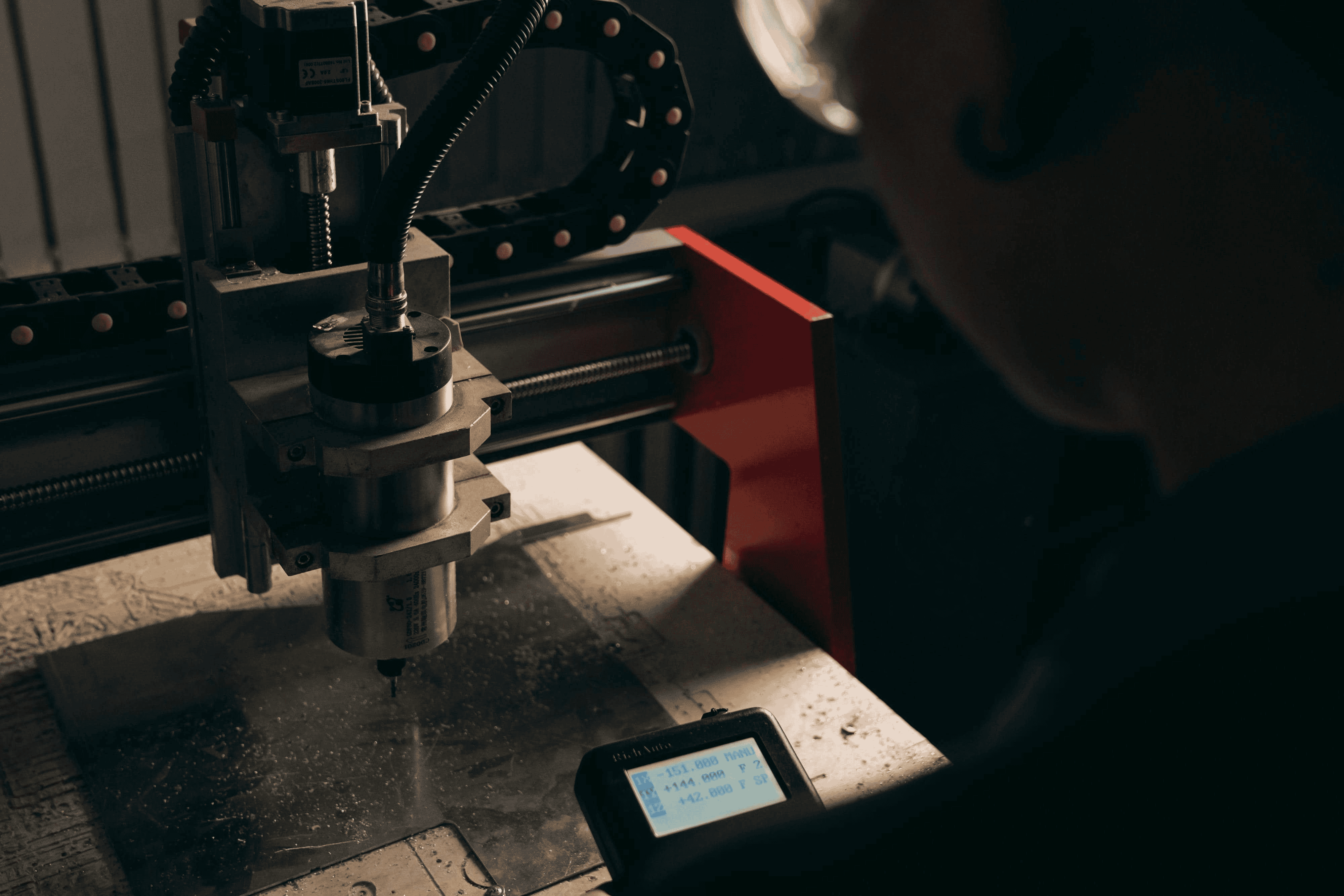

Equipment breadth matters. A well rounded operation will list TIG and MIG machines, a dedicated stainless bench to avoid cross contamination, precision saws, a press brake, a tube bender, and cutting systems such as CNC plasma or waterjet. For repeat parts, fixture tables and positioners improve accuracy and speed. If your project involves assemblies, confirm their ability to cut, form, weld, and finish under one roof to reduce lead time and hand offs.

Lead time and communication will make or break your schedule. Request a written quote that shows material, fabrication labor, finishing, and any engineering time. Clear terms make cost comparison easier and set expectations about deposits and delivery. For local projects in Fayetteville Arkansas and Northwest Arkansas, proximity can save days on pickup, fit checks, or prototype tweaks.

Accurate inputs produce accurate pricing. Provide drawings or step files, material type and thickness, weld symbols to AWS A2.4 if available, target tolerances, and finishing requirements such as passivation for stainless or powder coating for aluminum. Note any critical surfaces or dimensions that affect assembly. If you have performance requirements like pressure hold or food grade contact, state them early so the shop proposes the right process and inspection plan.

Once you have your shortlist, visit the facility if you can. Seeing fixtures, cleanliness, and flow in person tells you more than a dozen emails. A team that builds a variety of projects with consistent fit and finish is ready for complex parts, prototypes, or one off repairs. In Fayetteville Arkansas you can find a partner that understands both stainless and aluminum, supports short runs, and delivers the surface treatments your environment requires.

If you need a partner who can move from concept to built part with accountability, explore our Custom fabrication capabilities. We detail processes, materials, and shop strengths in our Fabrication services overview so you can match your project to the right workflow. Curious how we approach communication, quality checks, and delivery in Northwest Arkansas? Read more at Why choose OZK.

Whether you searched stainless steel welding near me, aluminum fabrication near me, or a general welding shop near me, the right checklist stays the same. Verify expertise on your material, look for disciplined prep and fixturing, ask about inspection steps, and get a clear schedule. With the right shop, your drawings become dependable parts that install smoothly and look as good as they function.

Ready to move from idea to finished work in Fayetteville Arkansas? Share your drawing set, material spec, and target delivery date. We will respond with a guided quote, confirm the critical details, and build stainless or aluminum components that meet your spec without surprises.

We're happy to talk specs, fitment, or just bounce ideas around.

Your parts deserve clean beads, accurate fitment, and timelines you can plan around. Tell us about your stainless or aluminum project and get a clear, fast quote from our Fayetteville Arkansas team. Submit the form and we will confirm scope, budget, and schedule so you can move from idea to finished part without guesswork.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com