Custom Fabrication

Welding certification is formal proof that a welder can produce sound, code compliant welds under defined conditions. It protects safety, reduces liability, and standardizes quality across industries like structural steel, pressure piping, and aerospace. Employers use certification records to match qualified people to specific procedures, base metals, and positions, which keeps projects on schedule and inspections predictable.

A common framework is the distinction between procedure and performance. A Welding Procedure Specification lays out the recipe for success, including process, polarity, amperage range, shielding gas, filler, preheat, and travel speed guidance. A Procedure Qualification Record proves that recipe can produce acceptable mechanical properties. Performance qualification shows the person can follow the recipe and meet visual and bend test criteria.

Certified TIG welder demonstrating GTAW technique during a welding certification test

Across the United States, the most cited standards include AWS D1.1 for structural steel, AWS D1.2 for aluminum, ASME Section IX for boilers and pressure piping, and API 1104 for pipelines. Each code carries unique essential variables and acceptance criteria. This is why two certifications might look similar but qualify different scopes of work.

TIG, also called GTAW, is favored for clean, precise welds on stainless, aluminum, and thin wall materials. A tig welding certification emphasizes control. Torch angle, arc length, heat input, filler timing, and shielding gas coverage all must be consistent. On stainless, purge gas on the root side often matters as much as the torch side. On aluminum, AC balance, frequency, and tungsten preparation become critical to clear oxide and maintain puddle control.

Test joints vary by code and application. Plate tests commonly use 3G vertical and 4G overhead positions to earn all position plate qualifications. Pipe tests often use 5G fixed pipe or 6G fixed pipe at a forty five degree incline for the broadest all position range. Thickness and diameter establish the base range of qualification, so the chosen coupon must match the intended production work.

For structural plate, AWS D1.1 tig certification can cover carbon steel with defined thickness ranges. For stainless plate, AWS D1.6 governs GTAW procedures and acceptance criteria. For pressure piping, ASME Section IX tests define essential variables like base metal P numbers, filler classifications, current type, shielding gas, and backing. The 6G position remains the gold standard for pipe because it forces the welder to manage gravity transitions while holding consistent fusion and reinforcement.

Success in tig welding certification starts with preparation. Clean the joint thoroughly, remove mill scale or oxide, and ensure tight, consistent fit up with the specified root opening. Dress tungsten to a crisp point for DC work or a smooth truncated tip for AC on aluminum. Use a gas lens when possible for better coverage and longer stickout around tight joints. Practice on the exact base metal and thickness range you plan to test on, and map out tack locations to control heat and alignment.

Inspectors usually begin with visual examination, checking bead profile, reinforcement limits, undercut, and surface porosity. Guided bend tests then reveal internal fusion and discontinuities; coupons are bent in face and root orientations to expose lack of fusion or inclusions. Some procedures use radiographic or ultrasonic testing to verify internal soundness. Acceptance criteria come straight from the chosen code, so understanding those limits before striking an arc is part of smart preparation.

Certification exams are administered by accredited test facilities, third party labs, or employer based programs with a Certified Welding Inspector overseeing the process. Documentation matters. Your test record will list the process, joint type, base metal, filler, position, thickness, and results, then define your qualified range. To keep the certification active, many programs require continuity logs that prove you have welded with that process at least once every six months. If continuity lapses or codes change, a quick retest brings you back into good standing.

The career benefits are tangible. A certified TIG welder is trusted with thin gauge stainless, food grade tubing, and visible cosmetic joints where quality cannot hide. In automotive and motorsport fabrication, TIG opens the door to chromoly and aluminum assemblies with strict fit and finish expectations. In structural and process piping, it enables high integrity root passes before switching to other processes for fill and cap, maximizing productivity and quality together.

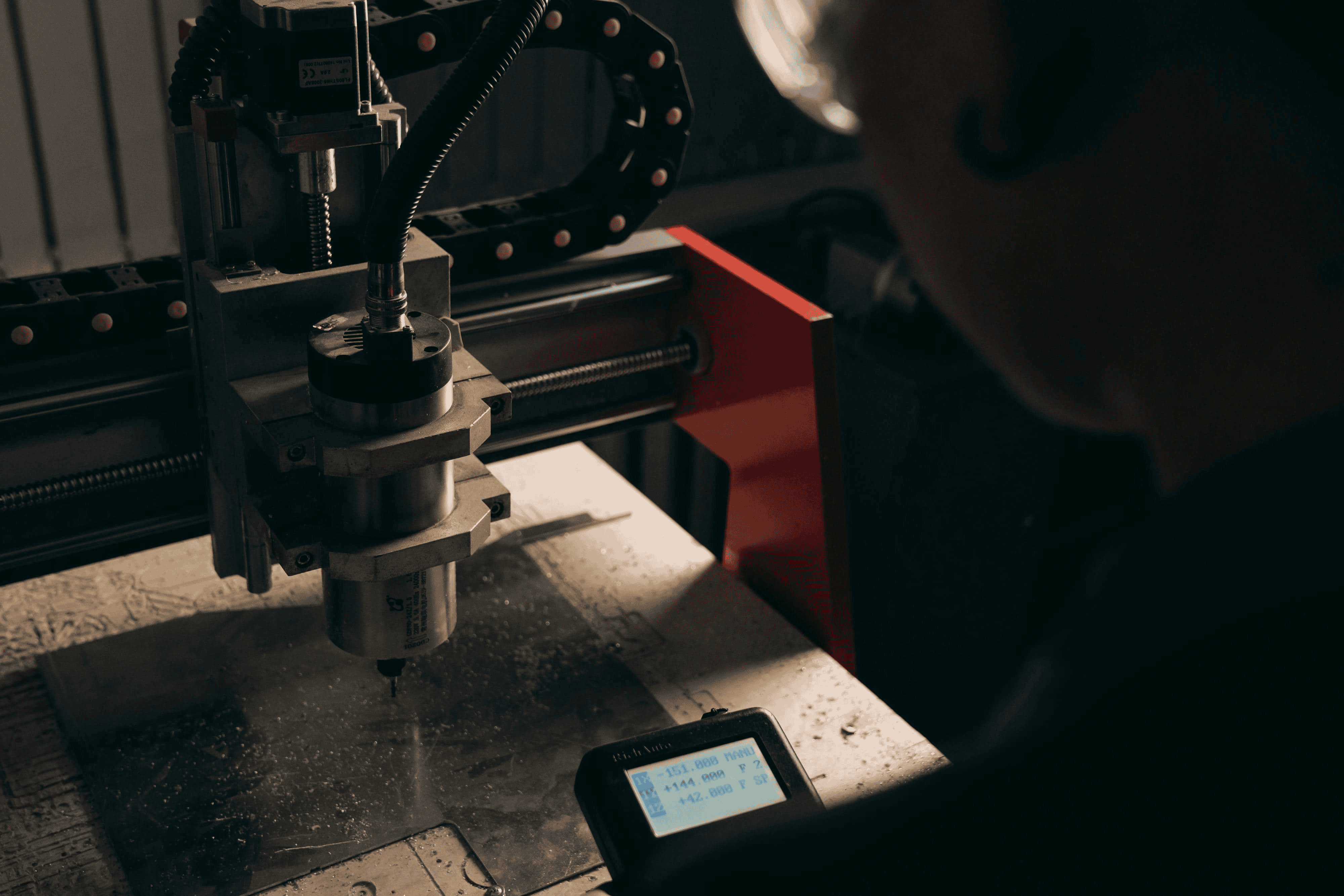

Real world success also depends on the environment you choose. Clean prep areas, stable fixtures, and purpose built jigs improve bead quality and consistency. That is why professional shops invest in fixturing tables, purge setups, and dedicated zones for stainless or aluminum. If you are seeking a team to bring certified precision to complex assemblies, explore our custom fabrication work, where certification is matched with design and repeatability.

At OZK Customs in Fayetteville Arkansas, TIG expertise supports projects ranging from van interior structures to bespoke exterior components and commercial assemblies. Our fabrication services include CAD driven design, precision cutting, and fixture based welding that keeps tolerances tight and finishes clean. If you want to understand how we approach quality, culture, and client communication, start with why choose OZK and see how our process translates into durable results on the road.

When you combine certification with thoughtful engineering and repeatable shop practices, TIG becomes more than a skill. It becomes a guarantee that the weld you approved on day one is the weld you rely on thousands of miles later. That is the promise we bring to every custom build and every component that leaves our floor.

Achieve the finish and strength your project deserves. Share your goals, materials, and timelines, and our certified TIG team will turn them into fixtures, procedures, and welds that pass inspection and look the part. From adventure vans to overland systems and commercial upfits, we design for real use and deliver with care.

We're happy to talk specs, fitment, or just bounce ideas around.

Planning a precision build that demands code compliant welds and clean TIG finishes? Our certified TIG team designs and fabricates for real world duty across vans, overland rigs, and commercial projects. Share your goals and we will map the safest, strongest path from concept to finished rig.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com