Custom Fabrication

Welding certification is a performance based credential that proves you can make repeatable, code compliant welds under defined conditions. Instead of a classroom quiz, you complete a supervised weld on a test coupon in a specific process, position, and material. The part is inspected visually and often with bend tests or other nondestructive methods. When you pass, the sponsoring facility records your qualifications so employers and clients can trust your skills.

Welding certification training and classes in a Fayetteville Arkansas fabrication shop

Codes and standards guide these tests. For structural steel and aluminum, many follow American Welding Society structural codes. Pressure piping and pressure vessels commonly reference ASME standards. A test will specify the process like shielded metal arc welding, gas metal arc welding, gas tungsten arc welding, or flux cored arc welding, the material type and thickness, and the position like flat, horizontal, vertical, or all position. Accredited Test Facilities register the results and issue documentation.

A solid foundation covers safety, power sources, joint prep, and metallurgy basics like heat affected zone and distortion control. In practical terms, you will learn:

Each process has nuances in travel speed, arc length, shielding, and parameter tuning. Mastering consistency is what earns the credential.

Expect a visual inspection for bead profile, fusion, and defect indications. Then the coupon may be cut and bent to reveal internal fusion. In some cases, radiographic or ultrasonic tests are used. Passing the test qualifies you for a defined range of thickness and position. You must keep a continuity log by making code compliant welds at defined intervals to keep the qualification current.

If you are starting from scratch, a structured training path matters. Search welding classes near me and compare community college labs, union training centers, and private schools. Look for modern power sources, a realistic student to booth ratio, clear safety culture, and time on each process. Ask how many hours are hands on and whether you will practice the exact joint types used in common certification tests.

Job outcomes matter. A strong welding program near me will publish placement rates and connect you with employers in fabrication, structural steel, pipeline, manufacturing, or specialty shops. Evening or weekend options help career changers. For funding, ask about apprenticeships, scholarships, and state programs. Tour the lab, meet instructors, and ask what codes they prep students to pass. Bring gloves and try a brief arc session if allowed to feel the setup and ergonomics.

Use a simple checklist:

A credential opens the door. Real value shows when you apply that discipline to parts that need to fit, seal, and survive in the field. Shops live and die by joint prep, fixturing, and distortion control, plus the skill to choose TIG for a thin aluminum bracket or MIG with pulse for a structural member. That is where certified welders turn training into dependable work.

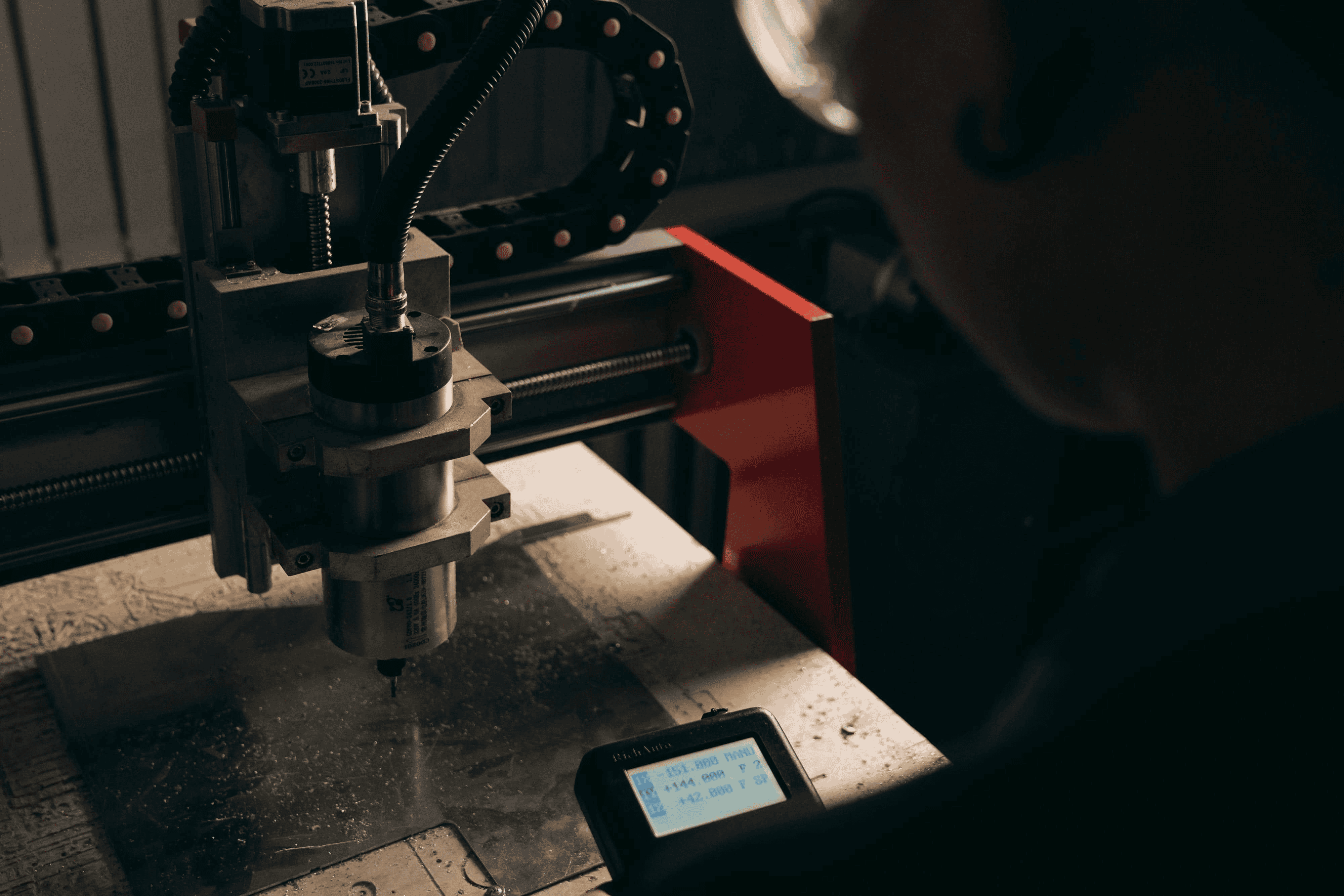

At OZK Customs in Fayetteville Arkansas, our team uses certified processes daily on steel, stainless, and aluminum for brackets, racks, bumpers, enclosures, and full vehicle systems. If you want your project built by people who live the craft, explore our custom fabrication. For a look at how we combine welding with CNC cutting, CAD, and final assembly, review our fabrication services. If you are choosing a partner and want to understand our approach to quality, timelines, and communication, see why choose OZK Customs.

Visit us in Northwest Arkansas to talk through materials, load cases, and finishes. We will translate your drawings into parts, select the right process, and build sample joints before moving to production. You will know exactly how your piece is made and why it will hold up on the trail or on the job.

Certifications tell us you respect procedure and can repeat quality. In a busy shop, that means less rework, cleaner fit ups, and predictable schedules. Bring your certification paperwork if you are collaborating with us on a specialized task so we can match procedures to your qualifications.

Ready to turn a sketch into something road ready. Share your timeline, materials, and use case. Our Fayetteville Arkansas crew will propose a practical path, from CAD and CNC to certified welds and final fit for a clean, durable result.

We're happy to talk specs, fitment, or just bounce ideas around.

Have a project that needs certified welding and precision fabrication in Northwest Arkansas? Tell us about your goals and timeline. Our team will review your specs and propose a practical path from sketch to road ready reality.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com