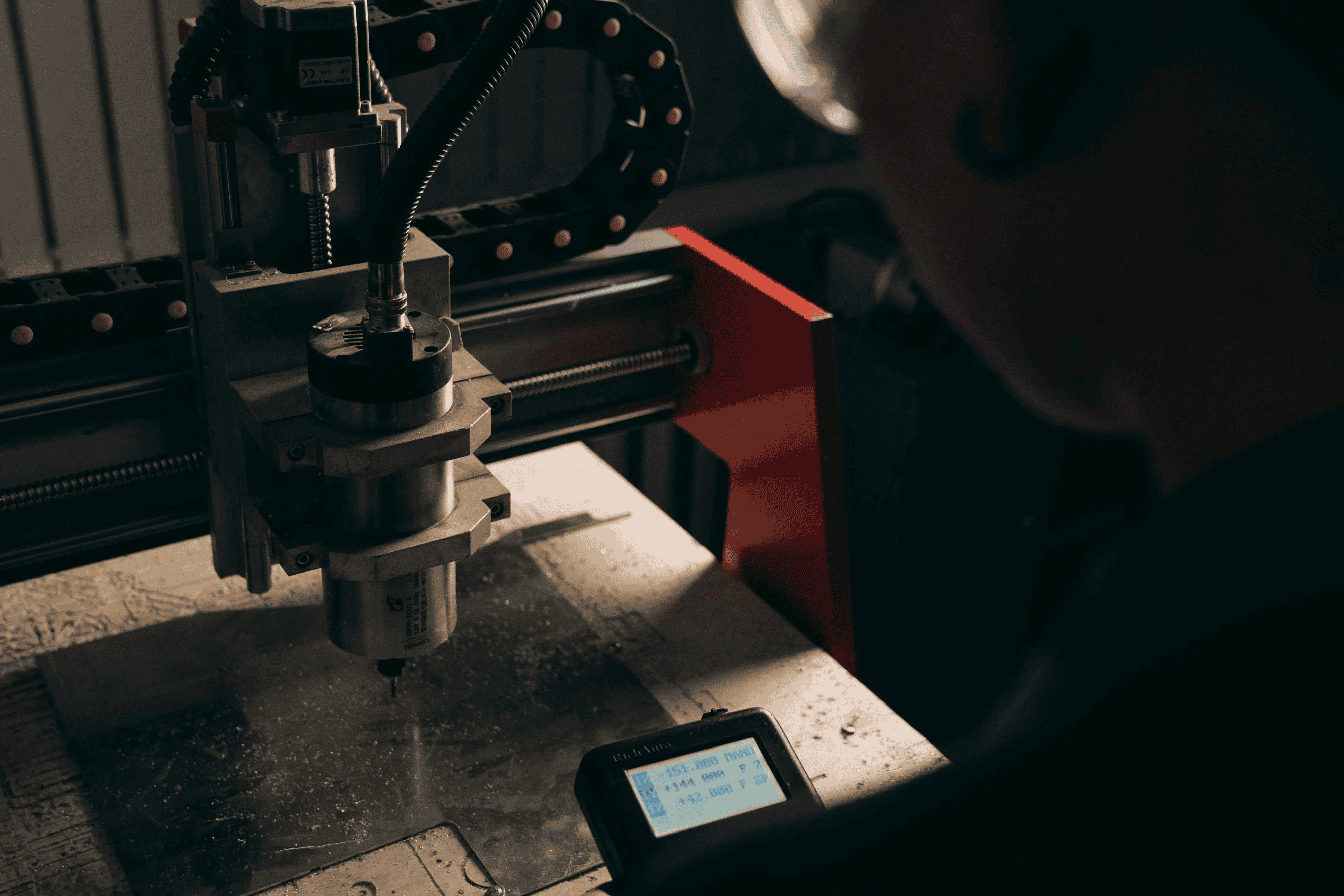

Custom Fabrication

Welding certification test plate prepped in a professional fabrication bay at OZK Customs, ready for procedure qualification

Welding certification is a performance based credential that shows you can make reliable welds to a defined procedure and code. In the United States, common codes include AWS D1.1 for steel structures, AWS D17.1 for aerospace, ASME Section IX for pressure work, and API 1104 for pipelines. A test supervisor records your identity, the process, filler, base metal, position, and parameters. Then your weld is evaluated by visual inspection and destructive or nondestructive testing such as bend tests, fillet breaks, radiography, or ultrasonic examination.

You do not need a degree to be a welder. Employers look for repeatable technique, safety awareness, and the ability to read drawings and follow a welding procedure specification. Many candidates ask what training do I need to be a welder. The path combines classroom basics with plenty of arc time. If you are wondering how hard is it to become a welder, the answer depends on coordination, patience, and practice.

How long does it take to become a welder varies widely. If you already have shop experience and strong hand skills, you might pass an entry certification in weeks. Starting from scratch, expect several months to a year to build consistency across positions. That covers flat, horizontal, vertical, and overhead for common processes like SMAW, GMAW, FCAW, and GTAW.

People often ask how long does it take to get a welding certificate or welding certification how long does it take. For a single process and position, some schools prepare students in six to twelve weeks. Multi process or code specific test prep can take longer. Apprenticeships stretch the timeline but add paid experience and broader exposure. Your timeline also depends on the test itself. Plate tests usually come faster than pipe, and open root pipe takes more practice.

What do you need to be a welder day to day. Start with personal protective equipment, a safety mindset, and the ability to control heat, travel speed, and filler deposition. What education is needed to become a welder is usually a high school diploma or equivalent, shop math, and basic metallurgy. Welding school requirements will include safety, electrical principles, joint design, and blueprint reading. Many schools include AWS sense aligned curricula. Do you need a diploma for welding. Most shops prefer at least a diploma or GED because it signals readiness for written procedures and documentation.

If your goal is entry level structural plate, you may certify within two to three months. Pressure pipe can take six months or more. How long to become a welder also hinges on attendance, instructor quality, and the hours you spend under the hood. The steps to become a welder are straightforward. Learn safety, pick a process, master positions, pass visual and bend tests, then maintain continuity logs to keep your certs active.

Welder education requirements are practical. You will study symbols, tolerances, materials, and quality control. Education needed for a welder rarely means a college degree, but advanced roles like welding engineering do require one. How much education does a welder need beyond school depends on your sector. Aerospace and pressure vessel work add more theory and documentation. Prerequisites for welding programs usually include basic math and the ability to lift and stand for extended shifts.

Qualifications to be a welder include passing a performance test and proving you can follow a procedure. Requirements to become a welder at many shops include a drug screen, fit test for respirators, and safety training. How to get into welding can start with a local technical school, community college, or entry position as a helper. What do you need to become a welder beyond school. A portfolio helps. Keep photos of root passes, caps, and test results.

What does it take to become a welder on the job. Speed with discipline. Shops value welders who prep joints correctly, control distortion, and communicate about fit up before the weld. How to become a welder who advances quickly. Cross train on processes, learn inspection tools, and understand why procedures specify amperage, voltage, preheat, and interpass control.

What training do I need to be a welder if I want stainless or aluminum. Plan to add GTAW and pulsed GMAW, plus cleaning and contamination control. How long does it take to be a welder comfortable with thin sheet and heavy plate. Expect different learning curves. Thin material punishes heat errors. Heavy sections require bevels, multiple passes, and attention to interpass temperatures.

Do you need a degree to be a welder. No. What education requirements for welders matter most. The ability to read prints, interpret symbols, and document work for quality. Education requirements for welders include safety, metallurgy basics, and process control. Welding school requirements will outline these modules before you touch a booth.

If you want a look inside a professional shop environment, explore our custom fabrication work. We bring certified welding, precision fitment, and inspection ready joints to vehicle frames, brackets, racks, and structural components. For a breakdown of capabilities from metals to finishes, see our fabrication services. Curious how we operate and why builders trust us with critical parts. Read why choose OZK to learn how we plan, build, and validate every piece before it leaves the bay.

Whether you are mapping the steps to become a welder or you already carry current certs, your skills can shape real world solutions. Bring us your design challenge and we will help you translate it into a welded component that performs on trail and on the clock.

We're happy to talk specs, fitment, or just bounce ideas around.

Ready to turn your skills into metal that matters? OZK Customs designs and builds serious adventure rigs and commercial solutions with certified welds, precision fitment, and in house fabrication. Tell us about your project and we will help you choose materials, joints, finishes, and a build plan that fits your use case and budget.

ADDRESS:

6159 E Huntsville Rd, Fayetteville, AR 72701

PHONE:

(479) 326-9200

EMAIL:

info@ozkvans.com